Micro Cleaner Gun

Micro Cleaner Gun

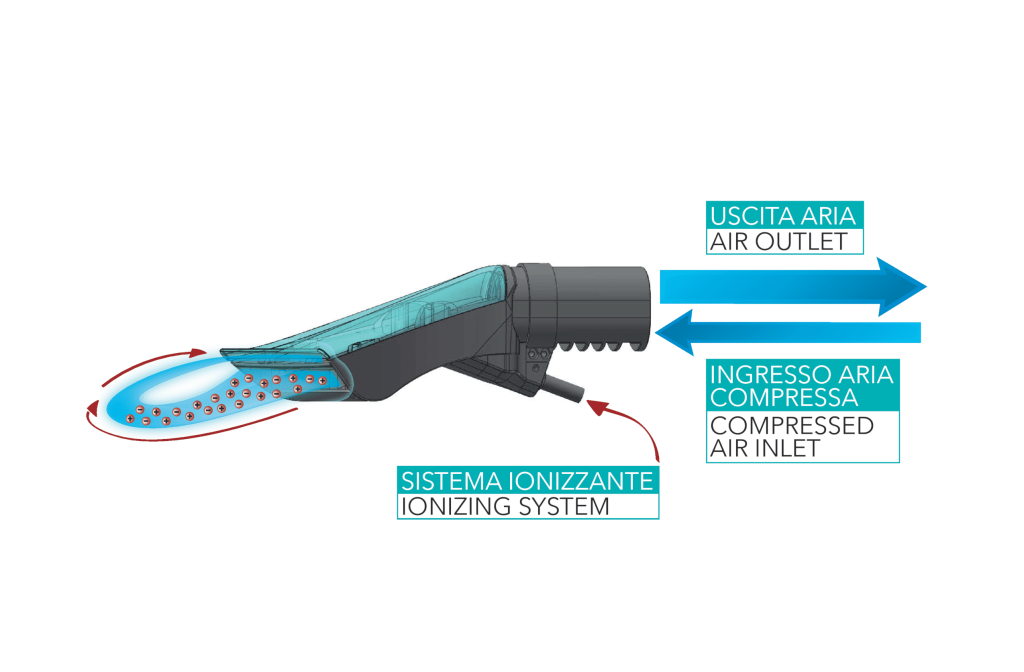

Operating principle

Micro Cleaner Gun is a manual dedusting system suitable for cleaning three-dimensional parts or complex surfaces with corners, ledges and holes.

The cleaning element, in one operation, blows ionized compressed air that removes dust, which is immediately vacuumed up. Ergonomic handle has switch that via solenoid valve turns compressed air on and off. Light weight makes Micro Cleaner Gun very convenient and easy to use.

The cleaning element is connected to an apparatus that independently provides compressed air, ionization, and suction. Three functions in one that enable maximum dedusting performance. The whole thing is enclosed in a metal cabinet on wheels, so it is easily moved.

The cleaning element is designed to reduce pressure drop and increase suction efficiency. It has three inputs (ionizer, compressed air, solenoid valve signal) and one output (aspirated air).

The discharge system consists of an ionizing element and a HAUG power supply. Compressed air, controlled by the solenoid valve, exits from the bottom of the cleaning element, here it is ionized and reaches the surface to be cleaned. The suction folds the airflow and directs it to the top where a tube takes it to the filter.

Turbulence is formed in the area where the flow is folded, which is very efficient in moving the powder, even to the most difficult places such as, for example, the inside of blind holes or edges.

| DATI | TECNICI | ||||

|---|---|---|---|---|---|

| Compressore: Serbatoio 6 L Pressione di esercizio regolabile (consigliata 2-3 bar) Potenza assorbita 0,55 KW | |||||

| Aspiratore: Capacità 20 L Prevalenza 20 KPa Potenza assorbita 1 KW | |||||

| Ionizzatore: Potenza assorbita 0,04 KW | |||||

| Peso totale 65 Kg Potenza assorbita totale 1,6 KW | |||||

| DATI | TECNICI | ELEMENTO | DI | PULIZIA | |

| W=100mm / 200 mm | |||||

| Peso 0,5 Kg (senza tubo) | |||||

| Aria | compressa | 2-3 | bar | ||

| Ionizzatore: OPI by HAUG cod.03.8510.000 | |||||

| Alimentatore: | EN-SL | LC | by | HAUG | cod.01.7833.300 |

- Three-dimensional surfaces such as plastic shells or painted sheet metal guards

- Wooden panels with ledges and blind holes

- Smooth but curved surfaces that cannot be treated with an automatic line

Videos and images

GALLERY

Do you want to request an offer?

Are you interested in receiving more information and being contacted by one of our specialized operators?

Request your offer now

Do you want to request an offer?

Are you interested in receiving more information and being contacted by one of our specialized operators?

Request your offer now

Frequently asked questions

These are machines that use technical brushes in their production process.

Dedusters, orienters, elevators, conveyors.

Industrial brushes are characterized by great adaptability to surfaces, great flexibility of use, and virtually unlimited variety of shapes and hardness. Therefore, the use of brushes in machines succeeds in being very efficient in many industrial processes.

In particular, dust collectors with brushes are more efficient than traditional non-contact dust collectors, while in the case of orienters, brushes replace other techniques (compressed air, vibration, etc.) managing to treat parts with low energy consumption, gently and quietly. The small footprint is another important advantage.

It can happen only if the brush is damaged due to an unforeseeable cause, such as a defective product that enters the machine and gets stuck in the brush destroying it, as on the other hand can happen with any other type of part in the machine. It should be mentioned that the same type of brush is currently used in pharmaceuticals and food without any problems.

Speaking of dust collectors, they are definitely cheaper than the main competitors.

As far as the orienters are concerned, they are aligned, but when looking at energy and space savings they are also more advantageous.

The customer sends us a few panels (sheet, film, etc.) that are treated in the lab with various dust collectors so that we can choose the one that gives the best results. The processed samples are then reviewed by the client for approval.

We generally have field test dust collectors available, which can be sent to the customer for limited periods of time.

No, the installation is done directly by the customer given its extreme simplicity. One must first evaluate the available spaces on the line, which sometimes contribute to the choice of the dust collector itself.

There is no one answer, as this time depends on many factors, such as product speed, materials, pressure, shifts, etc. As a broad indication, it can be said that a set of brushes can last between one and two years, sometimes longer.