Micro Cleaner Bar

Micro Cleaner Bar

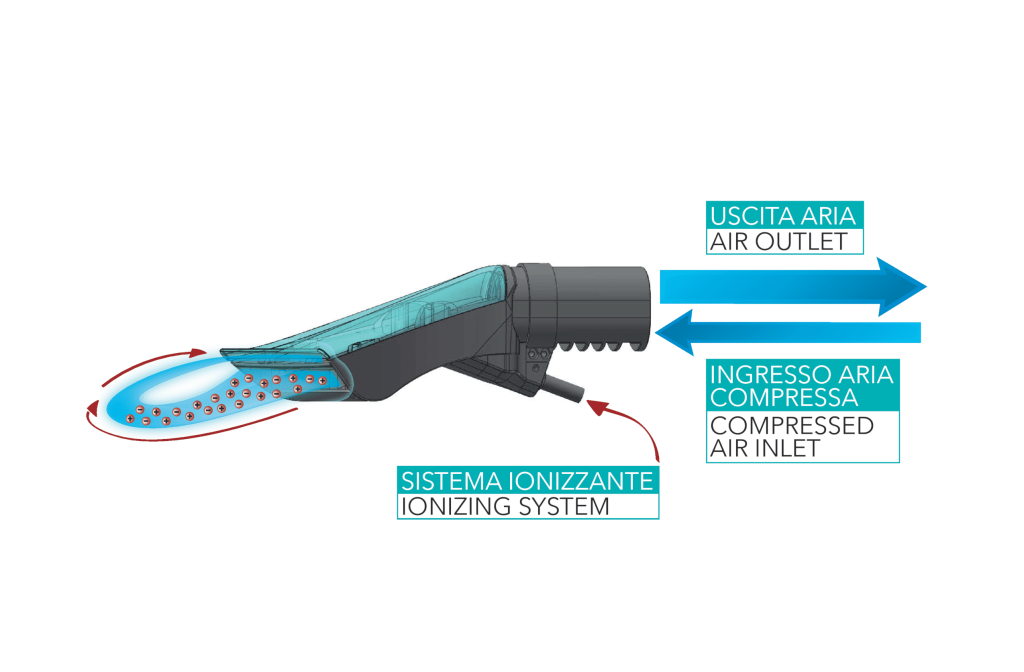

Principio di funzionamento

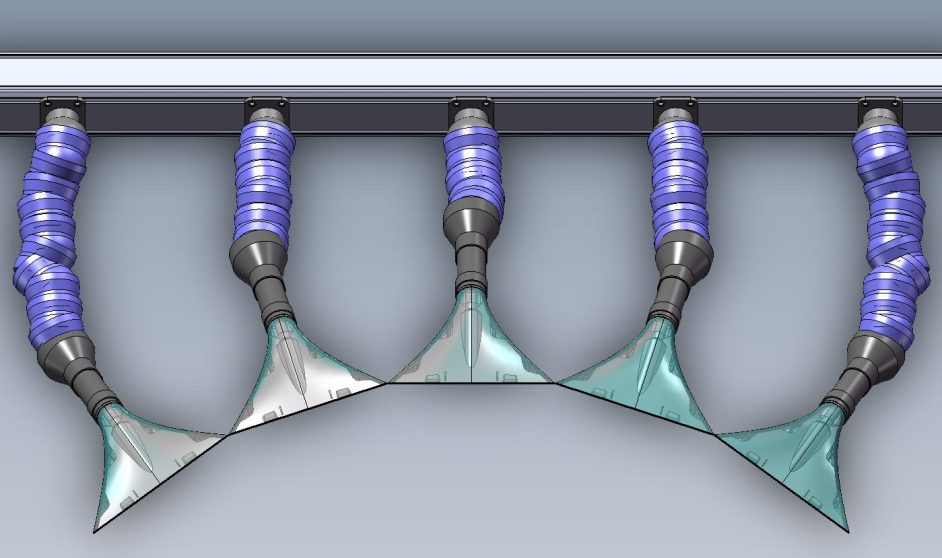

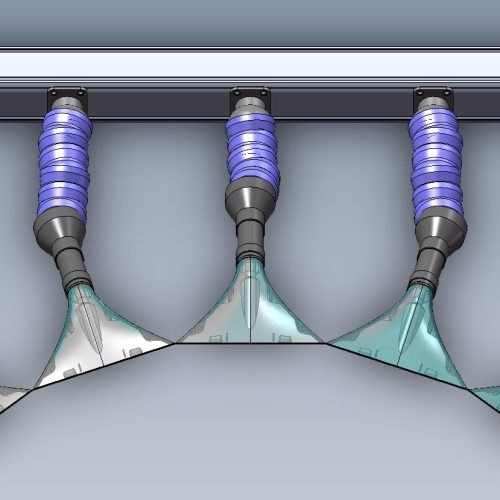

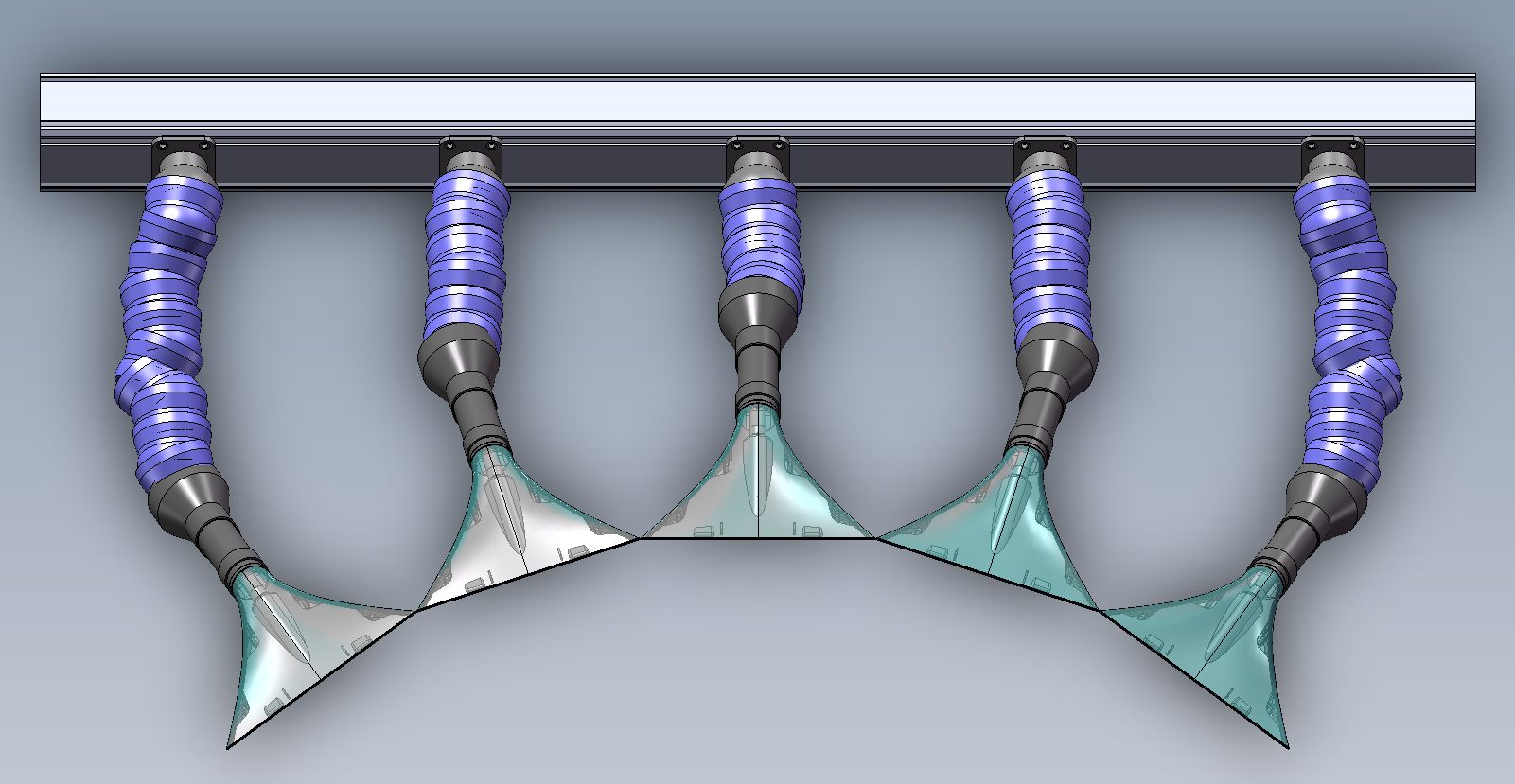

Vari elementi di pulizia possono essere montati su una barra soffiante/ aspirante realizzando un sistema per la depolverazione di pannelli in una linea automatica.

Sfruttando le molte cappe aspiranti, Micro Cleaner Bar può essere utilizzato per trattare pannelli curvi, adattando le cappe aspiranti per mezzo dei condotti snodati.

Vuoi richiedere un’offerta?

Sei interessato a ricevere maggiori informazioni e ad essere ricontattato da un nostro operatore specializzato?

Richiedi ora la tua offerta

Vuoi richiedere un’offerta?

Sei interessato a ricevere maggiori informazioni e ad essere ricontattato da un nostro operatore specializzato?

Richiedi ora la tua offerta

Domande frequenti

Sono macchine che utilizzano spazzole tecniche nel loro processo produttivo.

Depolveratori, orientatori, elevatori, trasportatori.

Le spazzole industriali sono caratterizzate da una grande adattabilità alle superfici, da grande flessibilità di utilizzo e varietà di forme e durezza praticamente illimitata. Per questo l’uso di spazzole nelle macchine riesce ad essere molto efficiente in numerosi processi industriali.

In particolare i depolveratori con spazzole sono più efficienti di quelli tradizionali senza contatto, mentre nel caso degli orientatori le spazzole sostituiscono altre tecniche (aria compressa, vibrazione ecc.) riuscendo a trattare i pezzi con bassi consumi energetici, in modo delicato e silenzioso. L’ingombro ridotto è un altro importante vantaggio.

Può succedere solo se la spazzola si danneggia per una causa imprevedibile, come un prodotto difettoso che entra nella macchina e si incastra nella spazzola distruggendola, come d’altra parte può avvenire per ogni altro tipo di particolare presente nella macchina. Va ricordato che lo stesso tipo di spazzola viene correntemente utilizzato in campo farmaceutico ed alimentare senza problemi.

Parlando dei depolveratori sono sicuramente più economiche rispetto ai principali concorrenti.

Per quanto riguarda gli orientatori sono allineati, ma se si guarda al risparmio energetico e di spazio risultano anch’essi più vantaggiosi.

Il cliente ci invia qualche pannello (lastra, film, ecc.) che viene trattato in laboratorio con vari depolveratori, in modo da scegliere quello che dà i migliori risultati. I campioni trattati vengono poi esaminati dal cliente per approvazione.

Generalmente abbiamo a disposizione dei depolveratori per test sul campo, che possono essere inviati al cliente per limitati periodi di tempo.

No, l’installazione viene fatta direttamente dal cliente vista la sua estrema semplicità. Naturalmente occorre prima valutare gli spazi disponibili sulla linea, che a volte contribuiscono alla scelta del depolveratore stesso.

Non esiste una risposta univoca, dipendendo questo tempo da molti fattori, come velocità del prodotto, materiali, pressione, turni di lavoro, ecc. Come indicazione di larga massima si può dire che un set di spazzole può durare tra uno e due anni, a volte di più.