Compressed Air Accessories

Compressed Air Accessories

Generalities

Nex Flow® specializes in manufacturing compressed air accessories for blowing, drying, cleaning, cooling and handling operations. We also provide technologies for optimizing compressed air use-on/off control, noise monitoring, flow measurement, and leak detection.

All accessories available

Nex Flow® specializes in manufacturing compressed air accessories for blowing, drying, cleaning, cooling and handling operations. We also provide technologies for optimizing compressed air use-on/off control, noise monitoring, flow measurement, and leak detection.

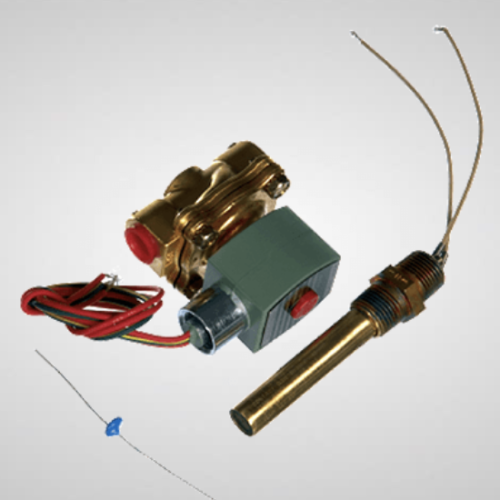

Electronic thermostat for Frigid-X

The ELC (Electronic Control Digital Thermostat) is a precise way to control one or two Frigid-X® cabinet coolers from Nex Flow® when you want to turn them on or off to save compressed air. While many applications require only a thermostat and solenoid system to regulate on/off, the ELC system offers more flexibility in control. On page 12 of the data sheet.

Pneumatic liquid and oil separators

The “super liquid separator” is a new pneumatic vapor removal system that does not use filters. The “pneumatic liquid separator without additional components” uses a special centrifugal technique together with specially designed “multiple radial nozzles,” creating a powerful rotational motion as compressed air passes through the unit. As the compressed air rotates, any liquid, oil or particles settle to the bottom of the separator.

Rigid Flex Hoses

Nex Flow’s RIGID FLEX hose has a unique, stainless steel construction that will not break after a few uses like rubber hoses with copper ends. It is resistant to leakage and bending. The product consists of the inner stainless steel tube, which is flexible but rigid, and an outer stainless coating to strengthen it and make it resistant to high pressures. The connections at each end are soldered to create a solid, high-quality system.

Articulated sleeves

When using blowing products, such as air nozzles, these may need to be mounted so that they have an adjustable blowing direction. High-quality, stainless-steel hinges for nozzles, sprayers, small air blades, and air amplifiers allow 25° movement from the central axis (a total movement of 50°) to direct and then secure the unit’s blow. On page 12 of the data sheet.

Pressure regulators with indicator

Pressure regulators are used to adjust compressed air pressure to the minimum necessary to operate a system properly. In many cases, companies install blowing products such as air blades, air amplifiers, etc. without a regulator, letting the product operate with any kind of pressure.

Self-draining filters

All Nex Flow® products used for blowing, cooling and conveying-be they air nozzles, air amplifiers, air conveyors, vortex tubes, panel coolers, tool coolers, etc. – require compressed air to operate. Therefore, it is important to use filters to remove liquids and oil from compressed air lines before installing the product. Filters are installed upstream of the product to be used.

Manual valves

Manual shut-off valves are offered as an option to turn on or off the air supply to any Nex Flow® product. These are simply two-way brass manual shut-off valves.

Mechanical thermostat for Frigid-X

The ELC (Electronic Control Digital Thermostat) is a precise way to control one or two Frigid-X® cabinet coolers from Nex Flow® when you want to turn them on or off to save compressed air. While many applications require only a thermostat and solenoid system to regulate on/off, the ELC system offers more flexibility in control. On page 12 of the data sheet.

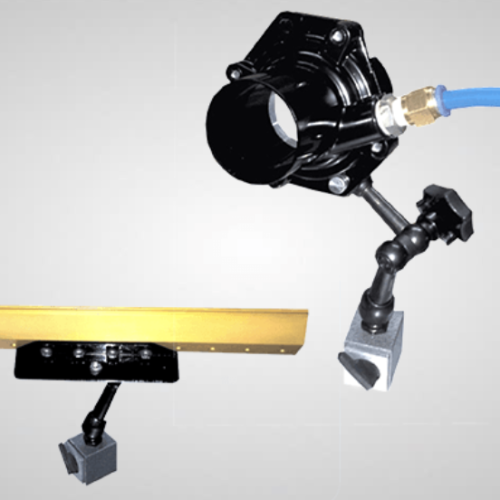

Mounting kit

Mounting systems for blades and air amplifiers provide a convenient and flexible way to use your cooling and blowing systems. All mounting systems are made of powder-coated steel. A knob locks the system after the air blade or amplifier is correctly positioned. An optional magnetic base can attach it to a ferromagnetic base. On page 3-4 of the data sheet.

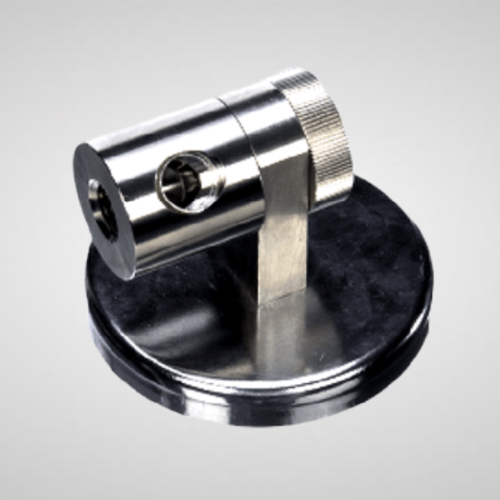

Magnetic Base

The magnetic base allows flexible mounting, either horizontally or vertically. An optional shut-off valve can be provided upon request. The base can have two sizes-one large and one small. The large magnetic base already comes with the adjustable coolers, while the small magnetic base comes with the small coolers. On page 12 of the data sheet.

Silencers

The silencers provide excellent sound reduction-up to 35 dBA-and better than sintered attenuators. They are also used to remove oil vapors. Air expelled from valves and cylinders may contain oil vapors that can have adverse effects on personnel health. Regulation 0SHA 29 CFR 1910.10 limits cumulative exposure to oil vapors to 4.32 parts per million (PPM) per eight-hour work shift.

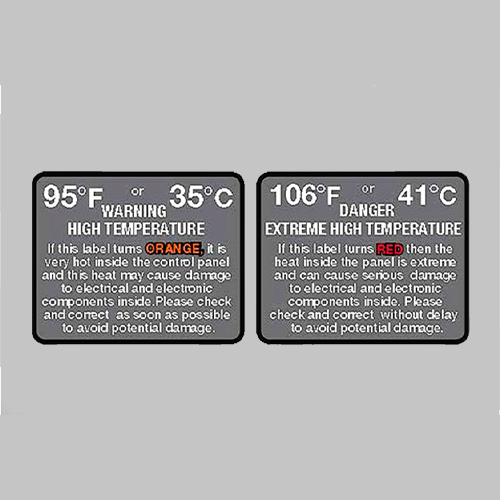

Thermal control adhesives

Electrical panels are vital to any industrial operation. Overheating of switchboards causes many problems, from sensor malfunction to unintended activation of programs. It is therefore essential to prevent them from overheating to avoid downtime and maintenance expenses.

AVG MAG-Drain

There are many types of self-drainage systems, many of which consume a small amount of compressed air to operate, regardless of whether they are float systems or solenoid valve systems. For air-intensive units, the savings are significant, especially when using a self-draining system with no leakage.

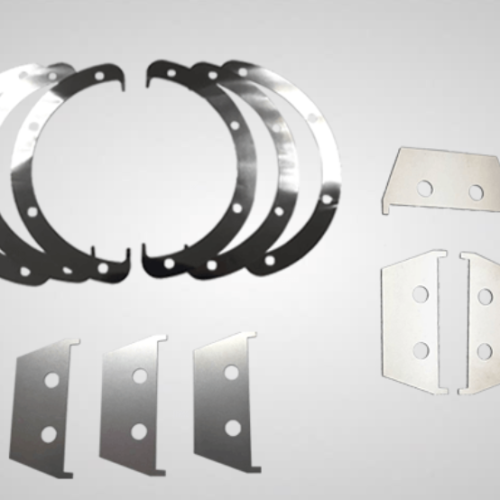

Stainless steel shim kit

Shim kits for Air Edger nozzles, air blades, air amplifiers, and air dryers. They are used to fix the openings of air blades, flat air nozzles, air amplifiers and air dryers. Some companies use plastic shims that deteriorate quickly, especially with moisture and dirt in the air ducts, which can cause uneven flow and downtime for replacement.

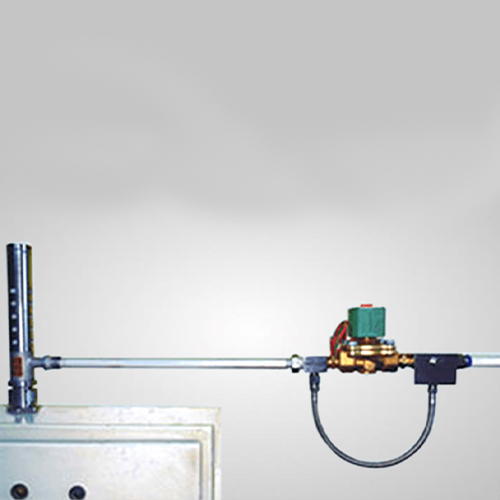

Overpressure of electrical panels

In very dirty environments, it may be advantageous for a small amount of compressed air to enter the control panel when the cooler is not operating (turned off using solenoid and thermostat to conserve electricity). This system maintains a constant overpressure in the electrical cabinet, preventing dust from entering.

End silencers for Frigid-X

A vortex pipe without a silencer can be quite noisy if there is no connection at the cold end to convey the cold air. The Cold End silencer reduces exhaust noise by up to 10 dBA and is a standard part of special vortex tube packages such as the Tool Cooler, Adjustable Spot Cooler and Mini Cooler systems. The Cold End is available in three sizes: one for the small vortex tube, one for the medium vortex tube, and one for the large vortex tube. All silencers are made of stainless steel with natural, environmentally friendly material inside to reduce noise. On page 7-8 of the data sheet.

Do you want to request an offer?

Are you interested in receiving more information and being contacted by one of our specialized operators?

Request your offer now