Our story

Our story

Simoni srl has been manufacturing brushes for 7 generations, since 1830. All these years of activity are a source of great pride for the Simoni family and, above all, represent a rare achievement, made possible only through passion passed on from generation to generation.

Technical capabilities have increased with the succession of generations that have evolved over time with the advancement of technology and new market requirements.

It is surprising how many different applications brushes can have in industry, and we can say that the ‘modern brushmaker’ must also have the ability to propose new solutions to the customer that always improve existing ones. It is easy to imagine that in this sea of shapes, materials and movements the customer often makes ‘impossible’ demands of us. We frequently hear that ‘the more impossible they are, the more fun we have’. This is perhaps the best summary of our company policy: while always striving for maximum simplification, we willingly accept to evaluate every customer proposal. Often, an ‘impossible’ request results in an interesting solution, which then has developments in other applications.

“In difficult times like these, my commitment is to continue the tradition, if possible introducing some innovations in the factory and well remembering the teachings of my father Paolo, who wanted first and foremost a company based on honesty and loyalty to others.”

The experience of an ancient tradition

1830

Foundation of the company in Calcara (Bologna), specialising in the production of hand brushes

1870

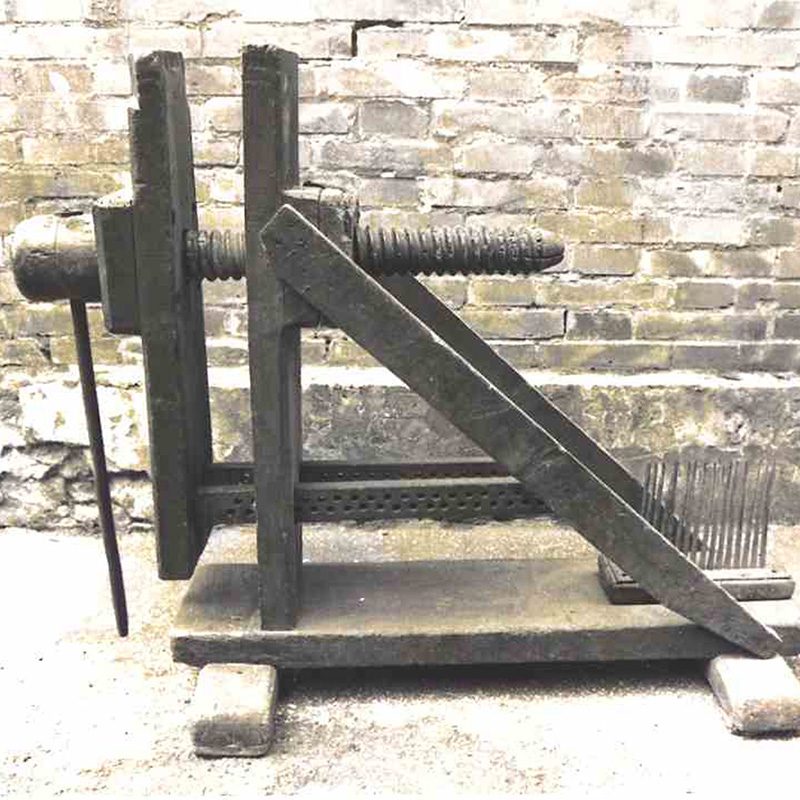

Introduction of the first brush-making machines

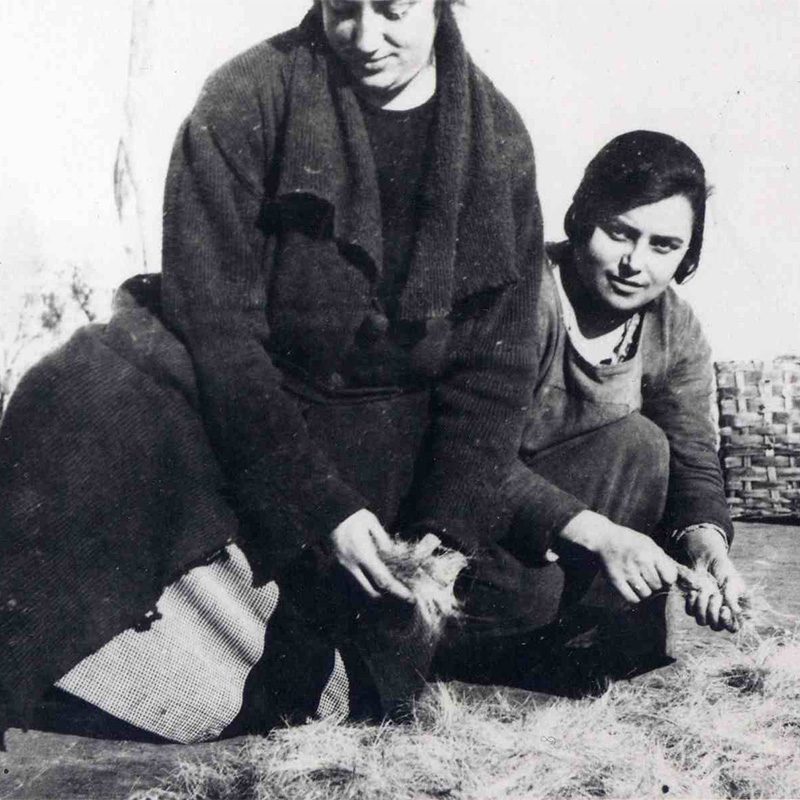

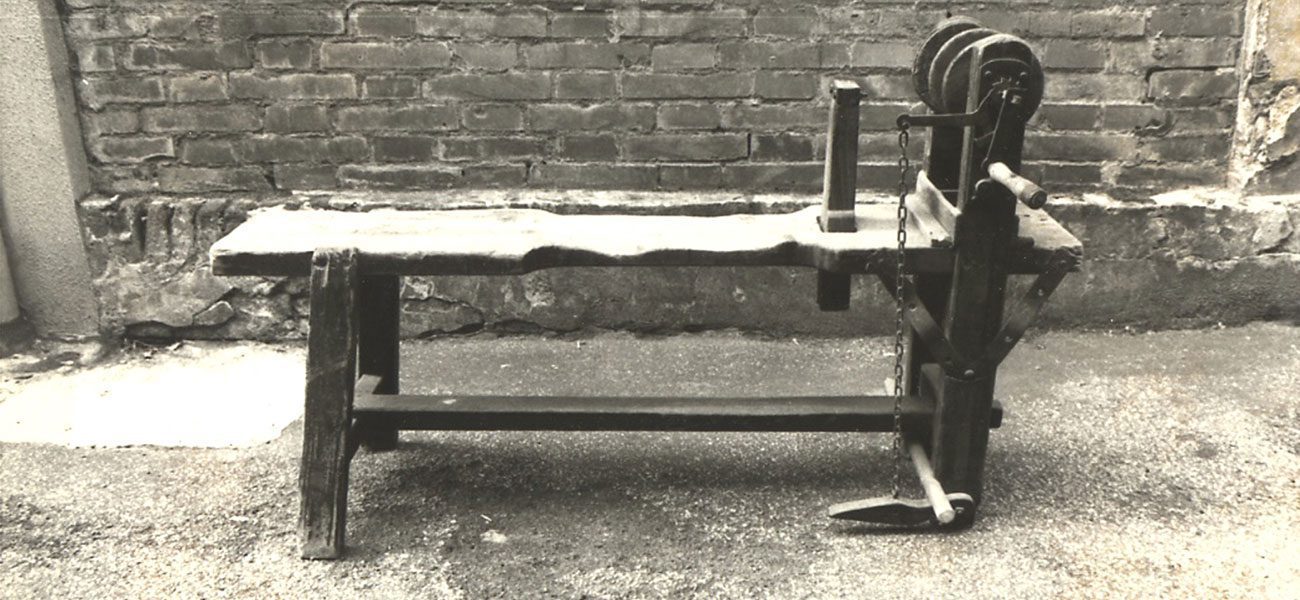

The first equipment dedicated to the manufacture of brushes was built in the mid-19th century. They were rudimentary, made entirely of wood and were operated manually.

The filaments of the brushes were assembled by hand on the pre-drilled wooden boards, in an operation known as ‘stitching’. A wire or hemp thread held the bundles on the plank. This method is still used today when one wants to give a greater guarantee of tightness (anchorage) to the bundles.

1960

Start of special production on drawings, as is still the case today.

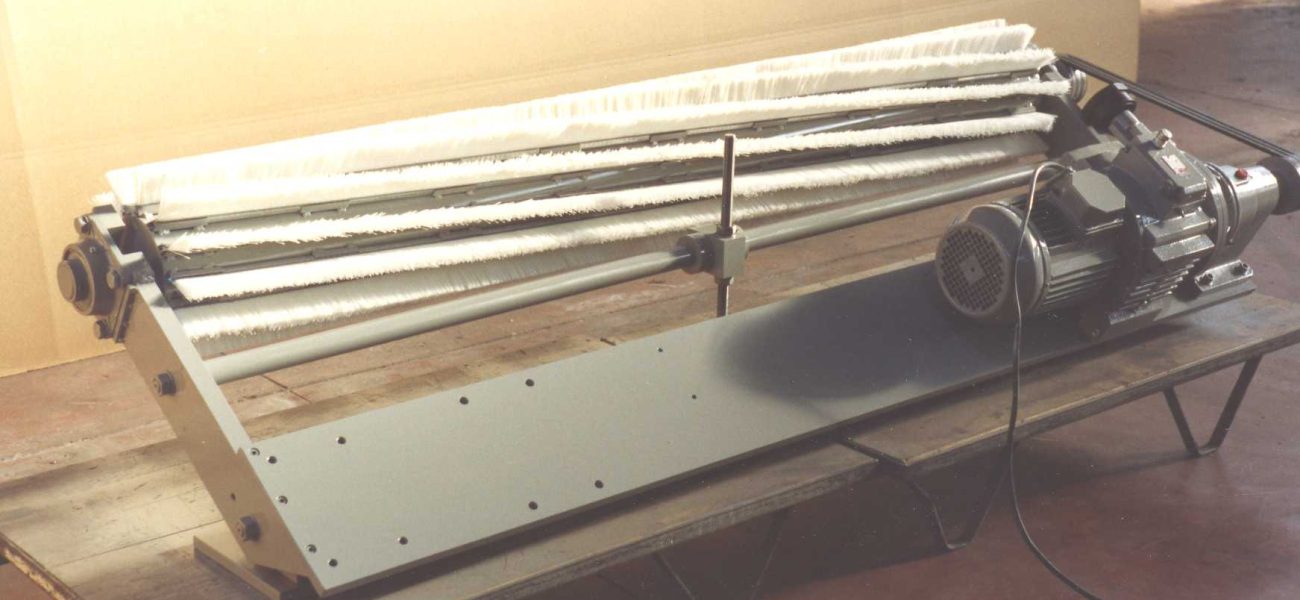

Introduction of the first ‘strip’ machine

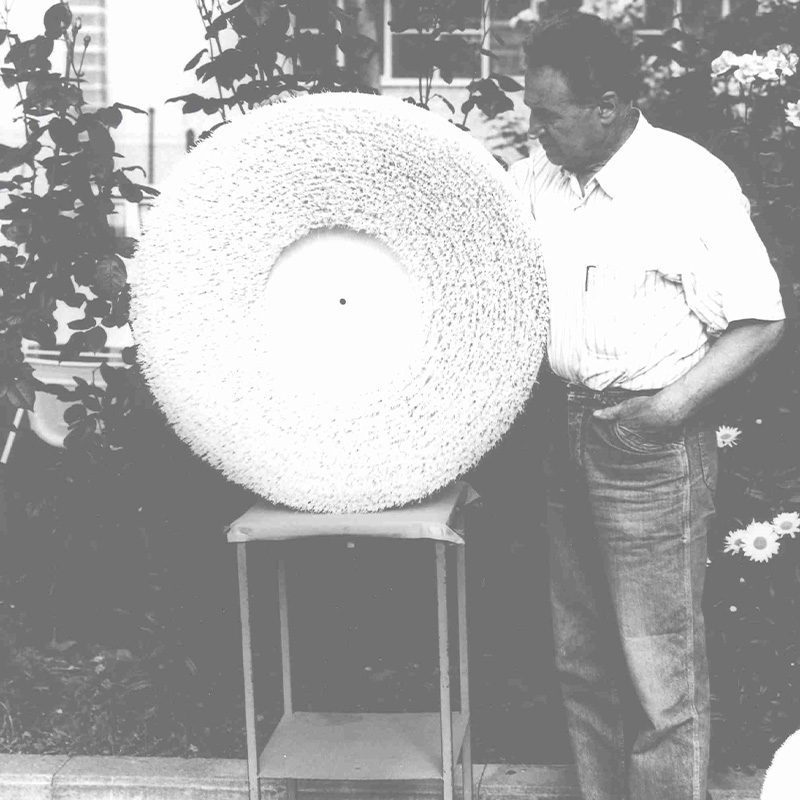

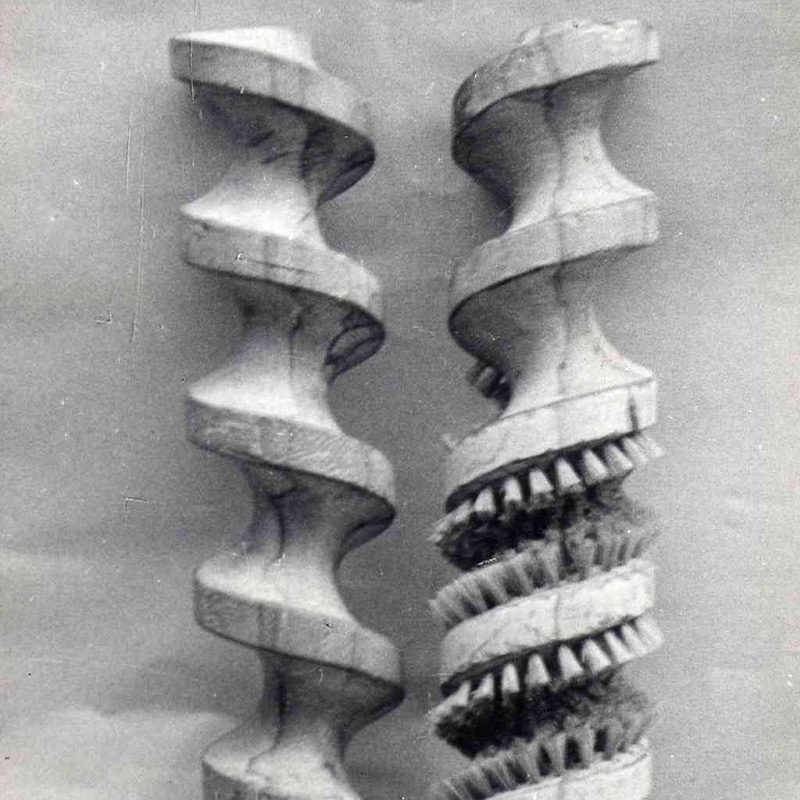

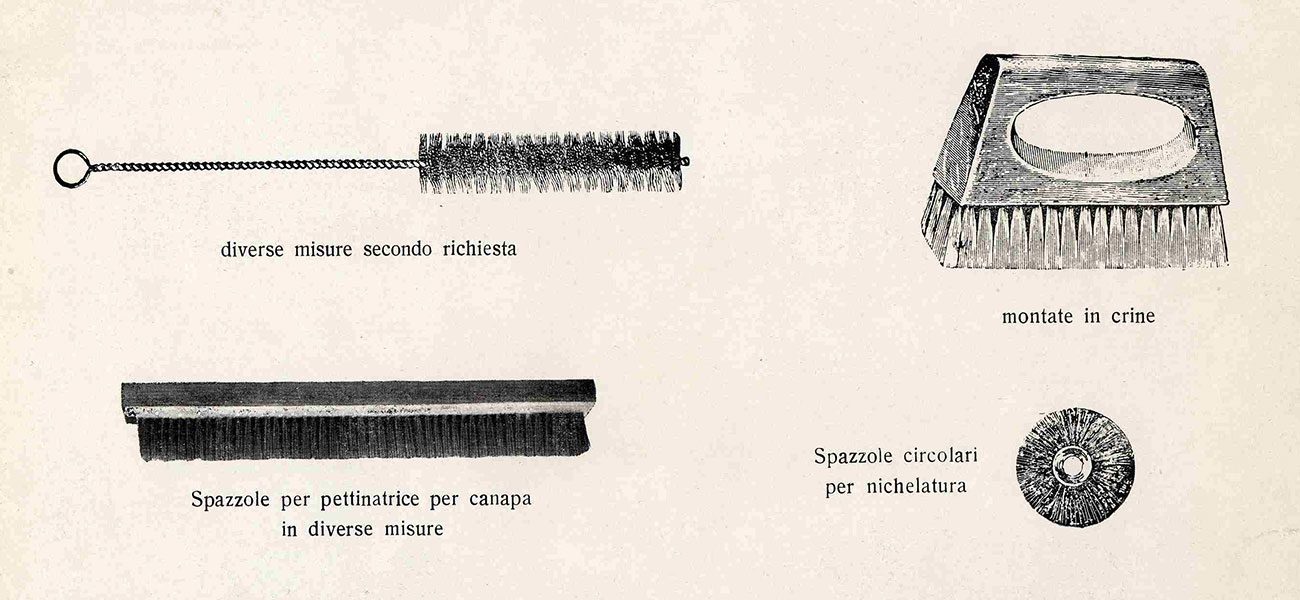

Following the economic boom of the 1960s, the company began the phase of special ‘customised’ production, which at the time led to an increasingly made-to-order and less and less catalogue-based business.

Furthermore, in 1960 the first stripe machine was introduced shortly after the first mechanical automatic machines. Paolo Simoni was the first to apply the strip brush method for fruit processing, offering a solid, inexpensive and quickly replaceable product. Soon the wooden and bristle modules were supplanted by strip, cylindrical and corrugated rollers.

1975

Abandonment of the production of traditional brushes for manual use and relocation to the current site in Zola Predosa (Bologna)

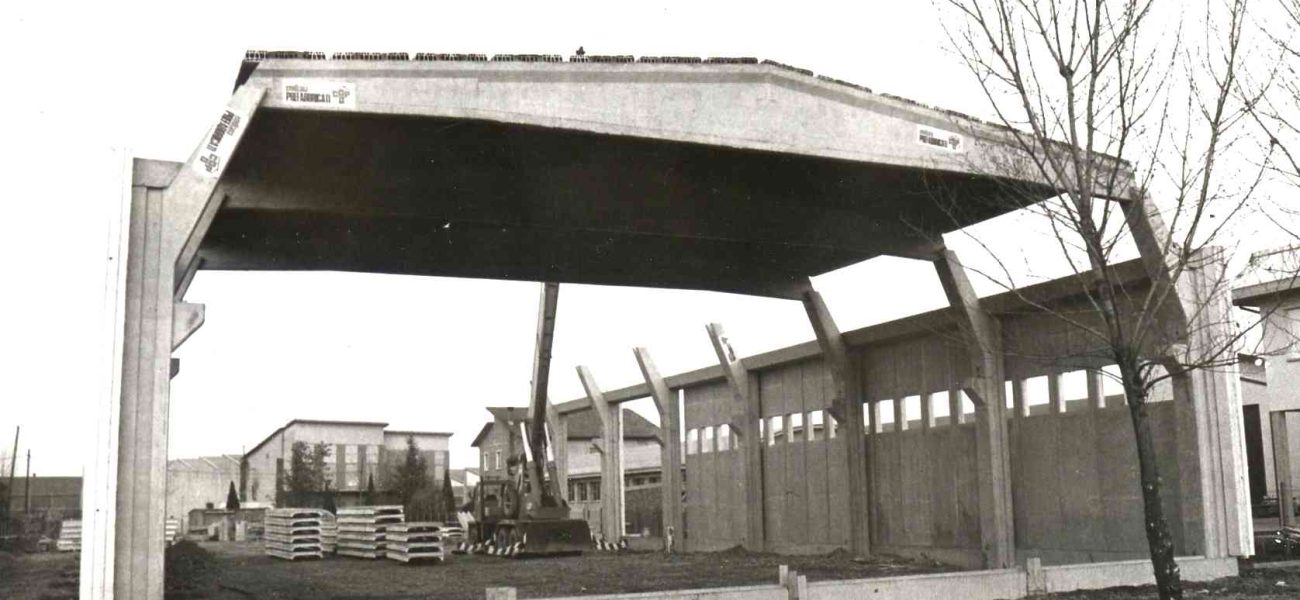

By the end of the 1960s, the factory premises in Via Rappini in Bologna were becoming increasingly cramped. Paolo Simoni began to mature the idea of moving the headquarters to an industrial area, out of the city where, among other things, logistical problems were increasing due to the accessibility of bulky means of transport.

In the mid-1970s, the new factory was built in Zola Predosa, an industrial area, very close to the city, well served by communication routes and rich in green areas.

1980

Introduction of the first numerically controlled punching machines

Since the 1980s, the logic of specialisation has been even more pursued and realised. Mechanical automatic machines had great rigidity and were only suitable for large production runs. This period saw the introduction of the first numerically controlled punching machines, which, with their versatility, opened up life to the manufacture of industrial brushes truly tailor-made for the customer. These machines brought information technology into the company, which then made a real revolution with the introduction of the first Personal Computers.

1983

In-house development of software for calculating quotations and work cycles

Since 1983, we have developed in-house dedicated software for calculating quotations and work cycles. This took several years to analyse and programme, and gave rise in the late 1980s to the legendary (for us) software package called ‘Scheda’, which inevitably underwent continuous technical and methodological updates.

Today, as then, this system allows us to rely on quick and reliable quotations and to keep all stages of production under control.

1999

Obtaining ISO 9001 quality system certification

2003

Acquisition of a new production site adjacent to the headquarters

In 2003, the building next to the Zola Predosa plant was acquired. This has allowed the company a more efficient operational layout and the possibility to introduce new machines to follow the development of production.

Currently, the factory has about 3,500 square metres of floor space over an area of about 7,000 square metres.