Brooms

Generalities

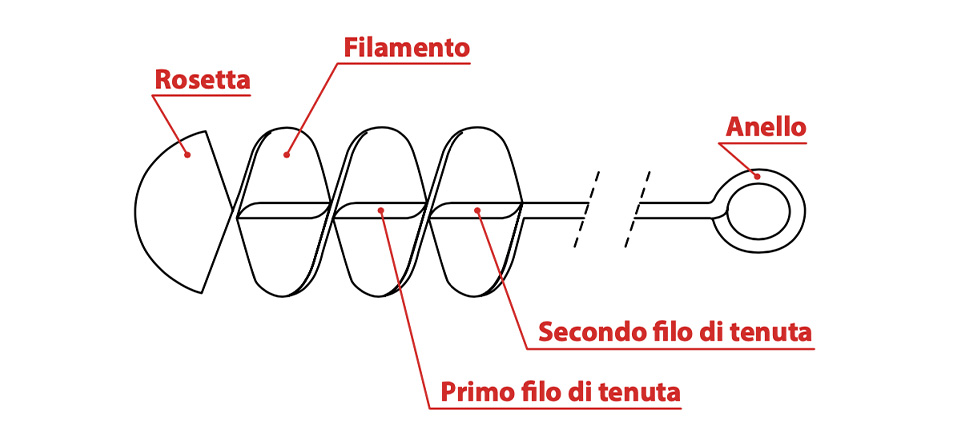

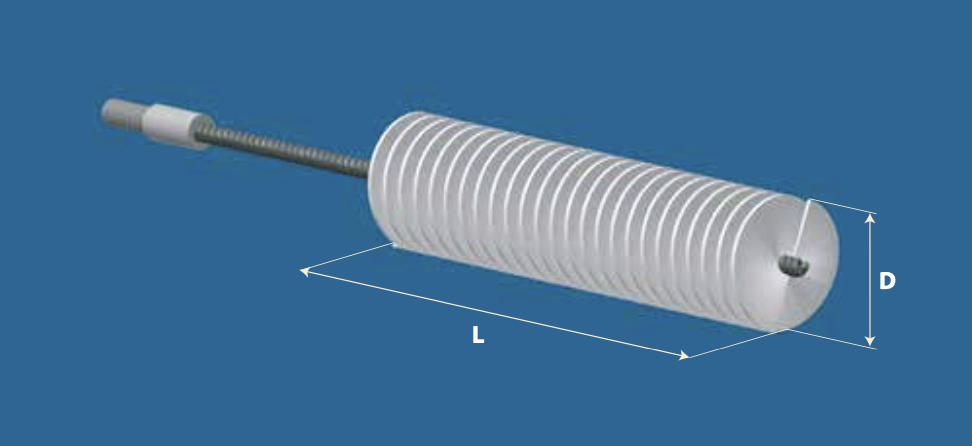

Brooms are brushes consisting of filament clamped between two metal wires twisted together. The result is a propeller-shaped brush (see Figure). If the brush is to be mounted on mechanical equipment, the metal ‘shank’ is usually sheared off on both sides. If, on the other hand, the use is manual, a part of the shank is left free of filament to be used as a handle, usually ending in a circular ring. The end of the brush can be folded over to make a small fan of filaments called a ‘rosette’, which serves to prevent the sheared wire from damaging the parts to be machined.

The main characteristic of pipe cleaners is the small core diameter, which makes them irreplaceable for internal cleaning of pipes, ducts and hard-to-reach crevices.

Brooms are used for:

- Cleaning and deburring holes, especially those smaller than 30 mm in diameter

- Cleaning curved channels, exploiting their flexibility

Videos and images

GALLERY

Do you want to request an offer?

Are you interested in receiving more information and being contacted by one of our specialized operators?

Request your offer now

Do you want to request an offer?

Are you interested in receiving more information and being contacted by one of our specialized operators?

Request your offer now

Frequently asked questions

What is the advantage of using a brush instead of another deformable object?

The special feature of the brush is that the working surface consists of millions of individual elements, which are the ends of individual filaments.

This gives the brush an adaptability that no other element, however deformable, can have.

How much must the brush interfere with the workpiece?

It depends on various factors. In a nutshell, it can be said that 2 mm is a good compromise. The important thing is that the brush filaments work ‘on the tip’ and not on the side.

Can a bundle of filament be detached from the brush body?

Depending on the materials used and the dimensions, there is a limiting tensile load that an individual bundle can withstand.

Beyond this limit, the bundle comes off, so the brush must be calculated according to use. This limit can be greatly increased by constructing ‘sewn’ or ‘tied’ brushes by hand, where instead of a single anchoring element, a continuous steel wire is placed.

Is it possible for a single filament to slip out of the bundle and contaminate the product?

This can only happen if the brush has a manufacturing defect, like any other type of object (e.g. a roller made of silicone flakes, one of which is defective and breaks).

When it is important that no contamination occurs, synthetic (not natural) fibres with a diameter greater than or equal to 0.15 mm should be used.

What softness or hardness of brush can I achieve?

Practically all degrees of hardness are possible, from very soft to very hard. In fact, hardness is a combination of the filament diameter, its free length and the density of the bundles.

Is it possible to have a certified 'food grade' brush?

Of course, we can provide FDA or FOOD GRADE certification and filament traceability.

Is it possible to have an ATEX-certified brush?

Unfortunately not, as it is the machine + brush assembly that needs to be ATEX certified, not the brush alone.

However, it is possible to supply the materials that the certifier requires, e.g. conductive bases, conductive filaments, etc.

Is it possible to 'regenerate' a worn-out brush?

Generally speaking, it is possible, but one has to assess whether it is cost-effective, which is not always the case. In addition, in the case of a punched brush, it is inadvisable to regenerate the brush more than twice, so as not to reduce the tightness of the bundles.