CONV-2000

Generalities

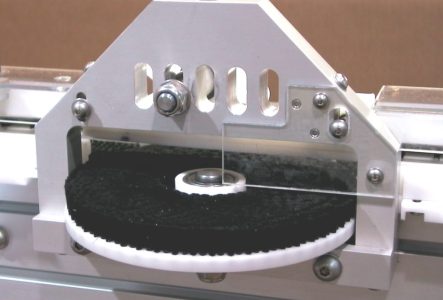

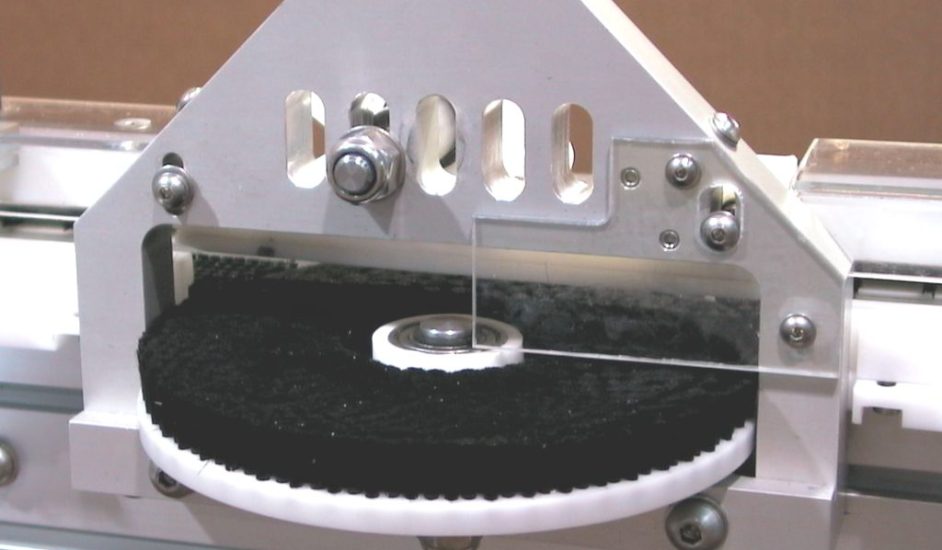

CONV-2000 is a brush conveyor, which can use one or two bristle belts.

The pieces slide over a low-friction surface that is also bristled. Size change is very easily achieved by changing the width of the transport channel. With this system, high flow rates are achieved, exceeding 1500 pieces/min per channel.

Videos and images

GALLERY

Do you want to request an offer?

Are you interested in receiving more information and being contacted by one of our specialized operators?

Request your offer now

Do you want to request an offer?

Are you interested in receiving more information and being contacted by one of our specialized operators?

Request your offer now

Frequently asked questions

Toggle title

These are machines that use technical brushes in their production process.

What are the main types of brush machines?

Dedusters, orienters, elevators, conveyors.

What are the advantages of this type of machine?

Industrial brushes are characterized by great adaptability to surfaces, great flexibility of use, and virtually unlimited variety of shapes and hardness. Therefore, the use of brushes in machines succeeds in being very efficient in many industrial processes.

In particular, dust collectors with brushes are more efficient than traditional non-contact dust collectors, while in the case of orienters, brushes replace other techniques (compressed air, vibration, etc.) managing to treat parts with low energy consumption, gently and quietly. The small footprint is another important advantage.

Can the brushes contained in the machines cause product contamination through filament loss?

It can happen only if the brush is damaged due to an unforeseeable cause, such as a defective product that enters the machine and gets stuck in the brush destroying it, as on the other hand can happen with any other type of part in the machine. It should be mentioned that the same type of brush is currently used in pharmaceuticals and food without any problems.

Are your machines economically competitive?

Speaking of dust collectors, they are definitely cheaper than the main competitors.

As far as the orienters are concerned, they are aligned, but when looking at energy and space savings they are also more advantageous.

How often should the brushes be replaced?

There is no one answer, as this time depends on many factors, such as product speed, materials, pressure, shifts, etc. As a broad indication, it can be said that a set of brushes can last between one and two years, sometimes longer.