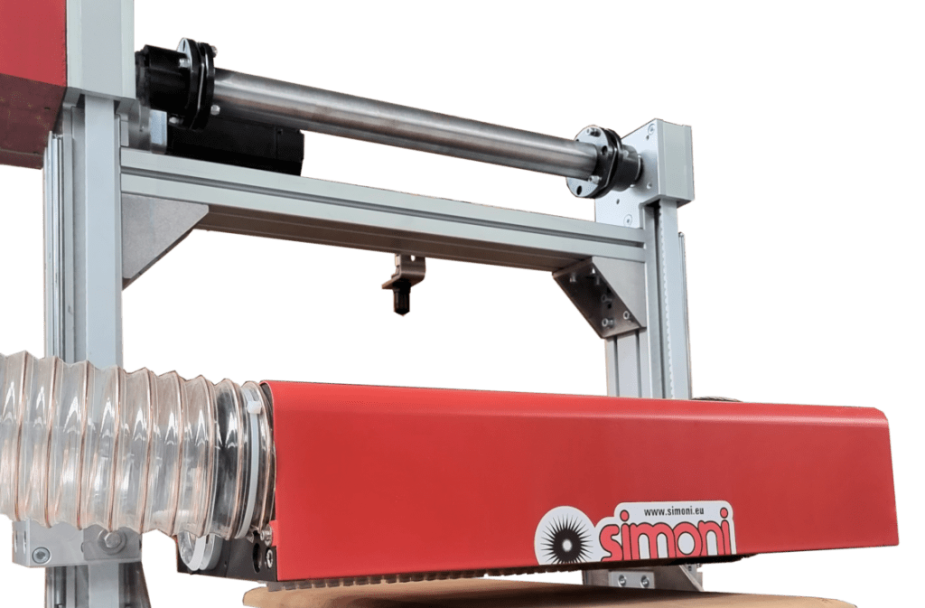

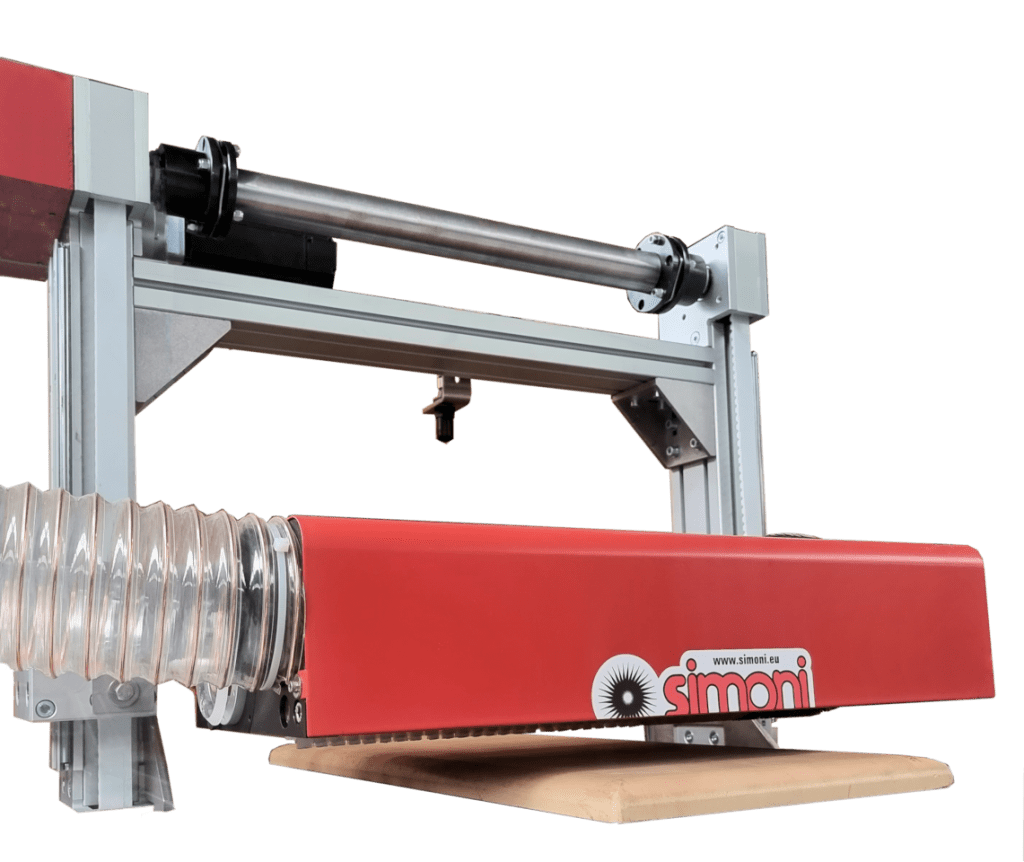

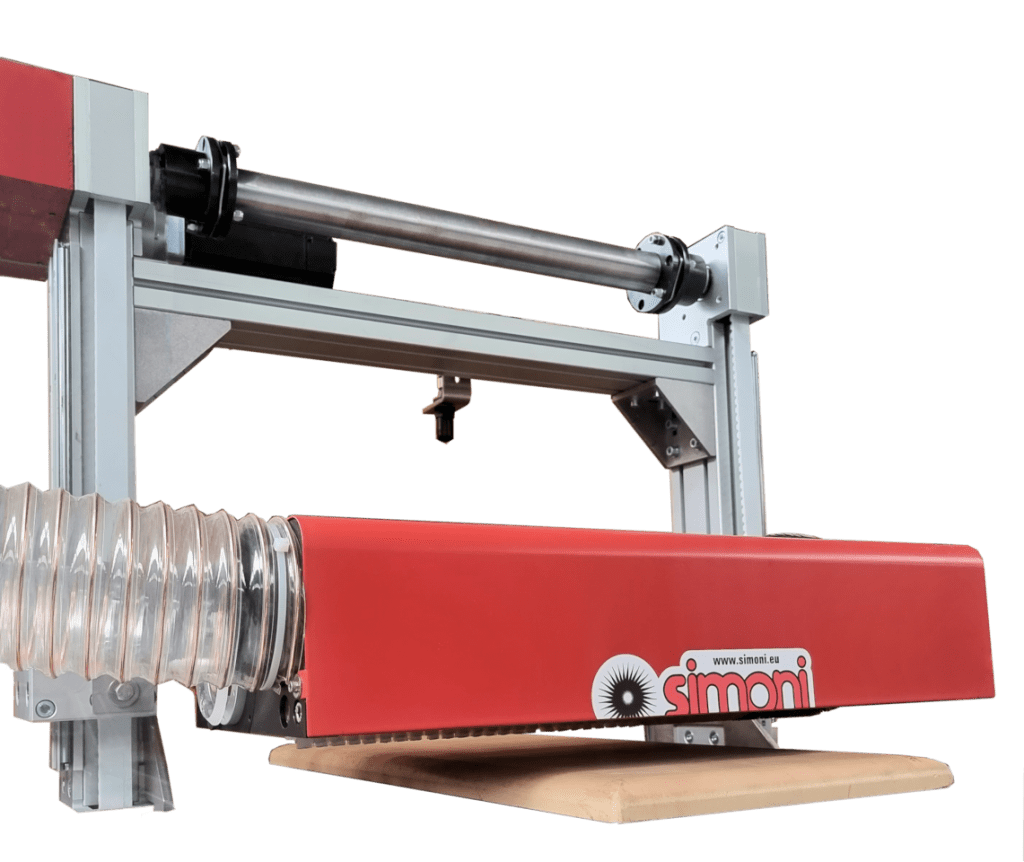

DEP120

Generalities

DEP120 is adust collectorfor the complete removal of dust from surfaces.

The brush is 120 mm in diameter and consists of interchangeable 100 mm long modules. Filaments may vary depending on the materials to be processed and the result to be obtained.

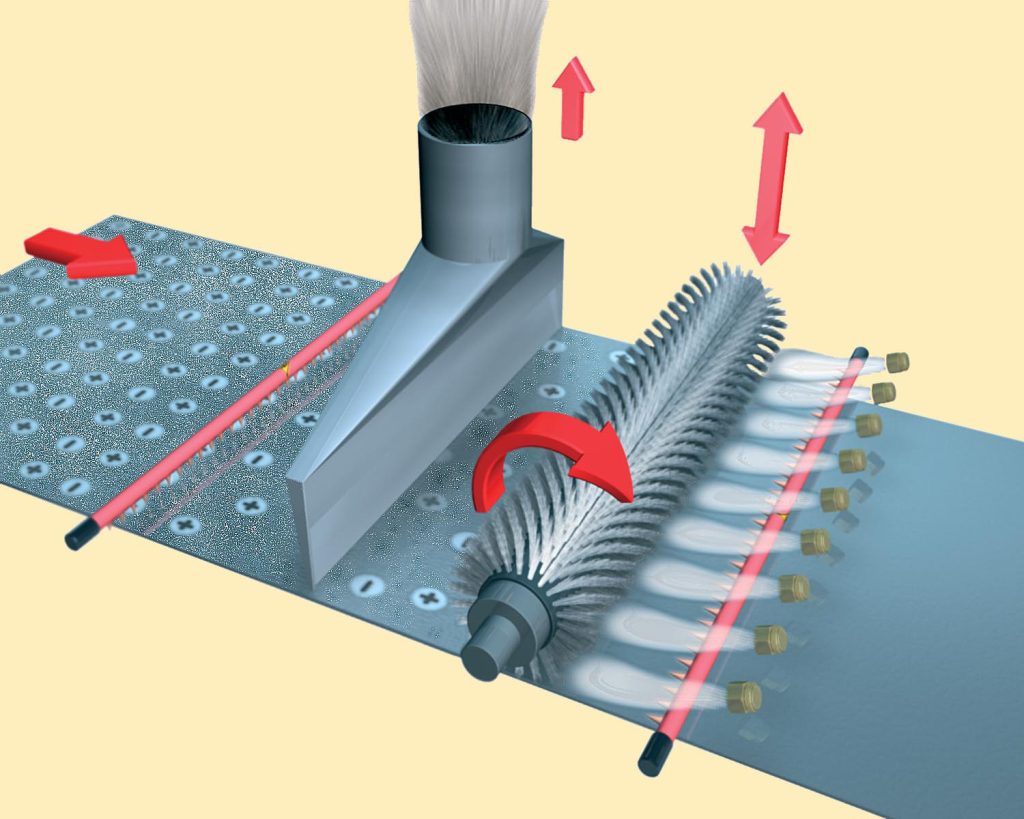

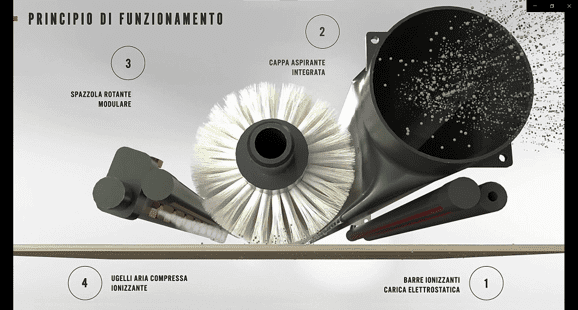

The principle of operation is as follows:

- The powder is de-ionized by an ionizing bar connected to a high-voltage feeder

- A cylindrical brush removes the dust thus neutralized and sends it toward a suction hood built into the machine

- The fume hood captures dust and sends it to a filter or collection system (external to the machine)

- A blast of ionized compressed air placed after the brush produces a barrier effect that captures any dust particles that may have escaped the brush, also performing the cleaning

- Automatically recovers brush wear

DEP120 is equipped with PLC with keyboard and display to control various functions:

- Brush working height, from 0 to 300 mm, for manual adjustment of contact pressure

- brush speed, from 0 to 2,000 rpm

- brush rotation, forward / backward

- operation with / without brush

- Automatic adjustment of the brush working height to the thickness of the material to be treated with wear recovery.

- contact pressure setting from 0 to 100 % DEP120 has limited overall dimensions, with a cross-sectional area of 210 x 270 mm.

The useful working length ranges from 500 to 2,000 mm. It is particularly suitable when complete surface dedusting is required.

We normally have a 500 mm machine to perform material testing.

| CARATTERISTICHE TECNICHE | |

|---|---|

| SPAZZOLA | D = 120 mm L = 500 – 2000 mm V = 0 – 2000 rpm Rotazione nei due sensi |

| MOTORE ELETTRICO | 230 V – 0,4 KW |

| ALIMENTATORE BARRE ANTISTATICHE | Ingresso 230 V Uscita 7000 V |

| VELOCITÀ DI TRATTAMENTO | max 200 m / min |

| DIMENSIONI WxHxL MM | 280x130x(L+180) |

| QUADRO ELETTRICO | 230 V |

| ASPIRAZIONE (A CURA DEL CLIENTE) PER L=1000 MM | V=1600 mc / h P=2500 Pa |

| CONSUMO ARIA COMPRESSA PER L=1000 MM P=2,5 bar | 600 NL/min |

NOTE: Suction characteristics are indicative only, varying drastically with the type of dust, its specific gravity, and environmental conditions (humidity, etc.)

Anti-static bar feeding and compressed air supply occur automatically when the machine is started.

Videos and images

VIDEO

GALLERY

Do you want to request an offer?

Are you interested in receiving more information and being contacted by one of our specialized operators?

Request your offer now

Do you want to request an offer?

Are you interested in receiving more information and being contacted by one of our specialized operators?

Request your offer now

Frequently asked questions

Toggle title

These are machines that use technical brushes in their production process.

What are the main types of brush machines?

Dedusters, orienters, elevators, conveyors.

What are the advantages of this type of machine?

Industrial brushes are characterized by great adaptability to surfaces, great flexibility of use, and virtually unlimited variety of shapes and hardness. Therefore, the use of brushes in machines succeeds in being very efficient in many industrial processes.

In particular, dust collectors with brushes are more efficient than traditional non-contact dust collectors, while in the case of orienters, brushes replace other techniques (compressed air, vibration, etc.) managing to treat parts with low energy consumption, gently and quietly. The small footprint is another important advantage.

Can the brushes contained in the machines cause product contamination through filament loss?

It can happen only if the brush is damaged due to an unforeseeable cause, such as a defective product that enters the machine and gets stuck in the brush destroying it, as on the other hand can happen with any other type of part in the machine. It should be mentioned that the same type of brush is currently used in pharmaceuticals and food without any problems.

Are your machines economically competitive?

Speaking of dust collectors, they are definitely cheaper than the main competitors.

As far as the orienters are concerned, they are aligned, but when looking at energy and space savings they are also more advantageous.

How is the choice between different models of dust collectors made?

The customer sends us a few panels (sheet, film, etc.) that are treated in the lab with various dust collectors so that we can choose the one that gives the best results. The processed samples are then reviewed by the client for approval.

Is it possible to test a dust collector before purchase?

We generally have field test dust collectors available, which can be sent to the customer for limited periods of time.

Is your assistance needed to install a dust collector on a production line?

No, the installation is done directly by the customer given its extreme simplicity. One must first evaluate the available spaces on the line, which sometimes contribute to the choice of the dust collector itself.

How often should the brushes be replaced?

There is no one answer, as this time depends on many factors, such as product speed, materials, pressure, shifts, etc. As a broad indication, it can be said that a set of brushes can last between one and two years, sometimes longer.