Filamenti

Filamenti

Generalità

Una spazzola è davvero un oggetto particolare. Complessivamente ha una forma geometrica ben definita e delle dimensioni precise, ma localmente la superficie di lavoro è formata da migliaia o milioni di piccoli cerchi, che sono l’estremità dei filamenti con cui la spazzola è composta. Questa caratteristica rende la spazzola diversa da ogni altro elemento meccanico utilizzato nella tecnica. Infatti la superficie di lavoro di una spazzola può essere rigida o morbida, orientata o isotropa, localmente variabile, e soprattutto ha una grande adattabilità alle irregolarità del pezzo da trattare. Ogni filamento si comporta in modo individuale anche se nel complesso fa parte di un’unica superficie di lavoro. I filamenti sono quindi gli elementi costitutivi fondamentali della spazzola.

Essi possono essere di tre tipologie:

- Sintetici

- Naturali

- Metallici

| Materiale | D | PS | A | Tmax | Tmin | R | RE | RC | FDA | Uso prevalente |

|---|---|---|---|---|---|---|---|---|---|---|

| PA 6 | 0.10-2.00 | 1.13 | 10 | +100 | -40 | 500 | 10¹¹ | X | ✓ | Alimentare, buona memoria elastica |

| PA 6.6 | 0.10-2.00 | 1.14 | 9 | +120 | -40 | 550 | 10¹¹ | X | ✓ | Alimentare, ottima memoria elastica |

| PA 6.12 | 0.07-2.00 | 1.06 | 3.0 | +110 | -40 | 440 | 10¹¹ | X | ✓ | Alimentare, ottima memoria elastica anche con acqua |

| PA 6.12 Abrasivo | 0.50-1.60 | 1.25 | 3.0 | +110 | -40 | 440 | 10¹¹ | X | Levigatura, satinatura, finitura | |

| PA HT | 0.20-0.80 | 1.18 | 3.7 | +160 | -20 | 400 | Alte temperature di esercizio | |||

| PP | 0.15-3.00 | 0.89 | 0.1 | +80 | -20 | 470 | 1016 | XX | ✓ | Alimentare, anche con acqua, sollecitazione meccanica leggera |

| PE | 0.30-1.00 | 0.92 | 0.1 | +70 | -50 | 170 | 10¹² | XXX | ✓ | Ambiente chimicamente aggressivo, superfici delicate |

| PBT | 0.20-3.00 | 1.31 | 0.35 | +100 | -40 | 420 | XX | ✓ | Alimentare, resistenza all’abrasione anche con acqua | |

| PEEK | 0.20-0.80 | 1.32 | 0.15 | +200 | 720 | XX | Alte temperature di esercizio ed elevate sollecitazioni | |||

| FIBRA DI VETRO | 1.00-3.00 | 1.91 | 0.25 | +155 | 1450 | Elevata resistenza all’usura | ||||

| THUNDERON | 0.03 | 1.28 | 0.8 | +150 | 5x10-¹ | Scarica elettrostatica | ||||

| CRINE CAVALLO | 0.12 med | 1.00 | 50 | +150 | -150 | 10¹⁶ | Alte temperature e superfici delicate | |||

| SETOLA MAIALE | 0.15 med | 1.10 | 40 | +150 | -150 | 10¹⁶ | Alte temperature, azione più incisiva rispetto al crine | |||

| PELO CAPRA | 0.05 med | 1.06 | 60 | +150 | -150 | 10¹⁶ | Superfici molto delicate | |||

| TAMPICO | 0.25 med | 0.86 | 35 | +160 | -150 | 10¹⁶ | Alte temperature, leggera abrasione |

|||

| ACCIAIO AR | 0.12-0.70 | 7.85 | +300 | 1900 | 1.7x10-⁵ | X | Pulitura e satinatura metalli duri |

|||

| ACCIAIO AAR | 0.12-0.70 | 7.85 | +300 | - | 2300 | 1.7x10-⁵ | X | Trattamento metalli con forte sollecitazione meccanica | ||

| ACCIAIO INOX | 0.12-0.50 | 7.90 | +450 | 2000 | 1.7x10-⁵ | XXX | ✓ | Alimentare, ambiente umido o aggressivo |

||

| ACCIAIO TEMPERATO | 0.20-0.70 | 7.85 | +350 | 2000 | 1.7x10-⁵ | X | Raschiatura meccanica profonda | |||

| ACCIAIO DOLCE | 0.06-0.40 | 7.85 | +200 | 650 | 1.7x10-⁵ | X | Pulitura e satinatura metalli teneri |

|||

| OTTONE | 0.06-0.30 | 8.50 | +160 | 900 | 7x10-⁶ | XX | Trattamento non aggressivo dei metalli | |||

| BRONZO FOSFOROSO | 0.06-0.50 | 8.80 | +160 | 950 | 7.5x10-⁶ | XXX | Trattamento non aggressivo dei metalli, ambiente chimicamente aggressivo. Anti-scintilla |

D: diametro filamento (mm)

PS: peso specifico (Kg/dm³)

A: assorbimento acqua (%)

T max: temperatura massima di esercizio (°C)

T min: temperatura minima di esercizio (°C)

R: carico di rottura a trazione (N/mm²)

RE: resistenza Elettrica (Ohm cm)

RC: resistenza Chimica (X = scarsa, XX = sufficiente, XXX = buona)

FDA: per uso alimentare conforme alla norma Food and Drug Administration (U.S.A.) Solo temperatura ambiente.

PA (nylon) 6 / 6.6 / 6.12

Il nylon (poliammide) è il filamento più utilizzato nelle spazzole tecniche. Per la sua elevata memoria elastica può lavorare sotto sforzo e poi riprendere facilmente la sua configurazione iniziale. È disponibile liscio, ondulato, bianco e nero, in una grande varietà di diametri.

PA 6.12 abrasivo

Il nylon abrasivo è molto utile in tutte le applicazioni che richiedono una notevole aggressività del filamento. È costituito da granuli di abrasivo in una base di nylon 6.12. I granuli possono essere di due tipi: Carburo di Silicio (SC) e Ossido di Alluminio (AO), che forniscono due qualità diverse di nylon abrasivo. Il filamento SC è più tagliente e quindi più adatto all’asportazione di materiale. Il filamento AO ha il granulo più arrotondato, pertanto è più adatto alle lavorazioni di finitura e lucidatura. La percentuale di abrasivo nel nylon è mediamente 30%. Sono poi disponibili varie granulometrie di abrasivo (esattamente come per la carta abrasiva) con differenti diametri del filamento (vedi Tabella).

PA HT

È un filamento a base nylon resistente alla temperatura fino a 160°C. Disponibile liscio in vari diametri.

PP

Il polipropilene ha meno memoria elastica del nylon, ma ha minor assorbimento all’acqua e maggior resistenza agli agenti chimici, quindi è preferibile in ambienti aggressivi. Disponibile in molti diametri fino ai più grossi (ovale mm 2×3), bianco, nero, liscio o ondulato.

PE

Il polietilene è il materiale che meglio resiste agli ambienti chimicamente aggressivi. È normalmente disponibile liscio nella tipica sezione ad X, che gli consente un effetto spazzolante delicato, e ciò può essere accentuato tramite la “piumatura”. Si tratta della sfrangiatura della parte terminale di ogni filamento, ottenuta con un apposito utensile. Le 4 canaline formate dalla sezione a X, per capillarità, rendono il filamento di PE adatto a trattenere liquidi, quindi indicato nelle operazioni di lavaggio di prodotti delicati, es. frutta.

PBT

Il poliestere è un filamento molto elastico ma che non deve essere soggetto a forti carichi in quanto se giunge allo snervamento perde le sue proprietà meccaniche. Ha buona resistenza all’abrasione e discreta resistenza chimica.

PEEK

È un filamento ad alta tecnologia che consente l’utilizzo con temperature di esercizio elevate, fino a 200 °C. È inoltre adatto ad elevate sollecitazioni meccaniche. Disponibile liscio in vari diametri.

Thunderon® (Acrilico Conduttore)

Thunderon è un filamento altamente tecnologico. Su base acrilica viene legato chimicamente del solfuro di rame. Ciò consente di ottenere un prodotto con la consistenza di un filamento sintetico ma con elevata conducibilità elettrica. È pertanto adatto a scaricare elettrostaticamente le superfici.

Rispetto alla fibra di carbonio ha numerosi vantaggi:

- maggiore conducibilità elettrica

- la fibra di carbonio non ha consistenza, mentre il Thunderon può spazzolare i pezzi

- mescolando Thunderon e nylon si possono ottenere tutte le durezze desiderate

- mentre le spazzole in fibra di carbonio sono disponibili solo in forma lineare, con il Thunderon è possibile costruire spazzole di ogni forma, anche rulli

Fibra di vetro

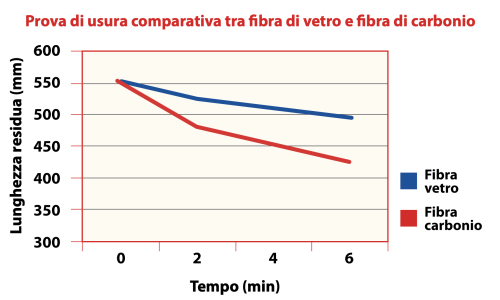

È un filamento molto rigido che ha come principale caratteristica quella di essere fortemente resistente all’usura. Disponibile solo diritto con diametri da 1 a 3 mm. È convinzione di molti che la fibra più resistente all’usura sia quella di carbonio. Per verificare abbiamo testato in laboratorio le due tipologie misurandone il consumo su carta abrasiva in funzione del tempo. Dal grafico riportato in figura si può vedere che la fibra di carbonio si usura ben più velocemente di quella di vetro

Caratteristiche PA 6.12 Abrasivo

| GRANA | DIAMETRO (mm) | SEZIONE e FORMA |

|---|---|---|

| 46 SC | 1.30 | tondo ondulato |

| 60 SC | 1.20 | tondo ondulato |

| 80 SC | 1.10 | tondo ondulato |

| 80 SC | 1.30 | tondo ondulato |

| 80 SC | 1.2x2.4 | piatto liscio |

| 120 SC | 0.60 | tondo ondulato |

| 120 SC | 1.10 | tondo ondulato |

| 120 SC | 1.30 | tondo ondulato |

| 120 SC | 1.2x2.4 | piatto liscio |

| 180 SC | 0.90 | tondo ondulato |

| 180 SC | 1.2x2.4 | piatto liscio |

| 240 SC | 0.80 | tondo ondulato |

| 320 SC | 0.60 | tondo ondulato |

| 320 SC | 1.2x2.4 | piatto liscio |

| 500 SC | 0.50 | tondo ondulato |

| 80 AO | 1.10 | tondo ondulato |

| 80 AO | 1.2x2.4 | piatto liscio |

| 120 AO | 1.2x2.4 | piatto liscio |

| 180 AO | 0.90 | tondo ondulato |

| 180 AO | 1.2x2.4 | piatto liscio |

| 320 AO | 0.60 | tondo ondulato |

| 320 AO | 1.2x2.4 | piatto liscio |

| 500 AO | 0.50 | tondo ondulato |

| 600 AO | 0.50 | tondo ondulato |

| 600 AO | 0.40 | tondo ondulato |

Crine di cavallo

È il materiale più tradizionale, con cui si sono sempre fabbricate le spazzole. È molto elastico e nello stesso tempo delicato, per cui può pulire a fondo il pezzo senza alterarne le superficie. Molto indicato anche per alte temperature e per rilasciare film liquidi sulle parti da trattare.

Setola di maiale

È leggermente più spessa del crine di cavallo, quindi un po’ meno delicata. Il filamento all’origine è molto più corto rispetto al crine, per cui non è possibile realizzare spazzole con mazzetti lunghi più di circa 30 mm.

Pelo di capra

Filamento molto fine e morbido, si utilizza per il trattamento delle superfici più delicate. Le spazzole in pelo di capra devono solo sfiorare la superficie in quanto le sua morbidezza non consente di applicare carichi.

Fibra vegetale Tampico

Dall’agave essiccata si ottiene la fibra di Tampico (o Mexico), che prende il nome dal porto da cui tradizionalmente partivano le navi con l’esotico materiale. È una fibra dal caratteristico colore giallo, che resiste a temperature elevate ed ha anche un’azione leggermente abrasiva. Si possono realizzare ottime mescole con il nylon ottenendo un’ampia gamma di durezze.

Acciaio Alta Resistenza (AR)

Trafilando l’acciaio la struttura cristallina del metallo si orienta in modo da ottenere un carico di resistenza a rottura (R) molto superiore a quello del metallo in barra. Noi utilizziamo normalmente un filamento con R=1900 N/mm2. È disponibile ondulato, zincato o nero. La composizione chimica dell’acciaio è riportata in tabella.

Composizione chimica media dell’acciaio AR

| Elemento | % |

|---|---|

| C | 0.520 |

| Mn | 0.623 |

| P | 0.004 |

| S | 0.010 |

| Si | 0.203 |

Acciaio Altissima Resistenza (AAR)

È un filamento di qualità superiore, con R=2300 N/mm2. È quindi indicato per notevoli sollecitazioni meccaniche, e soprattutto per cicli di fatica, come avviene nelle spazzole rotanti. È disponibile ondulato, normalmente ottonato.

Acciaio inox

Disponibile nella qualità AISI 304 e solo su ordinazione nella qualità AISI 316. Molto utilizzato non solamente nelle applicazioni per uso alimentare ma anche per trattamenti superficiali di particolari inox, in modo da evitare il deposito di particelle che con il tempo si potrebbero ossidare.

Acciaio temperato

È un filamento molto duro indicato per forti raschiamenti. Deve lavorare di punta in quanto raggiunge facilmente la rottura per fatica se piegato. Disponibile solo liscio.

Acciaio Dolce (Bessemer)

È un filamento molto tenero, con elasticità quasi nulla. Viene utilizzato prevalentemente in diametri molto piccoli per trattamenti di superfici metalliche delicate. È disponibile solo ondulato.

Ottone

Viene utilizzato per la pulizia di superfici metalliche soprattutto non ferrose, quando si richiede una aggressività minore di quella dell’acciaio. Disponibile in diversi diametri ed ondulato.

Bronzo Fosforoso

Ha un utilizzo simile a quello dell’ottone, ed inoltre è indicato in ambienti chimicamente aggressivi per la sua ottima resistenza. Viene inoltre utilizzato per evitare scintille durante il contatto con le superfici.

Gli utilizzatori di spazzole metalliche spesso richiedono dati tecnici sui carichi massimi a cui le stesse possono essere sottoposte durante il lavoro. Questo carico varia a seconda dell’utilizzo della spazzola (moto alternativo/rotante), della velocità e della geometria.

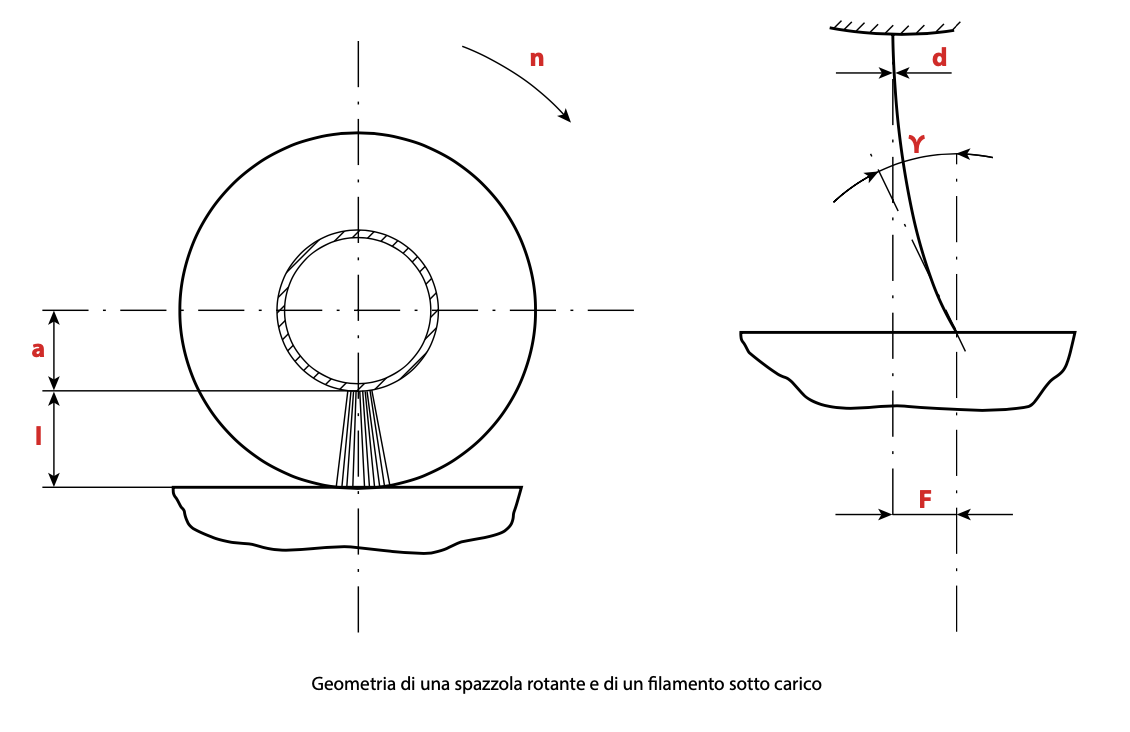

Il problema è stato da noi studiato teoricamente basandosi sulle ipotesi di lavoro più generali possibile, ottenendone una relazione matematica. In figura è mostrata la geometria di una spazzola rotante con i relativi parametri.

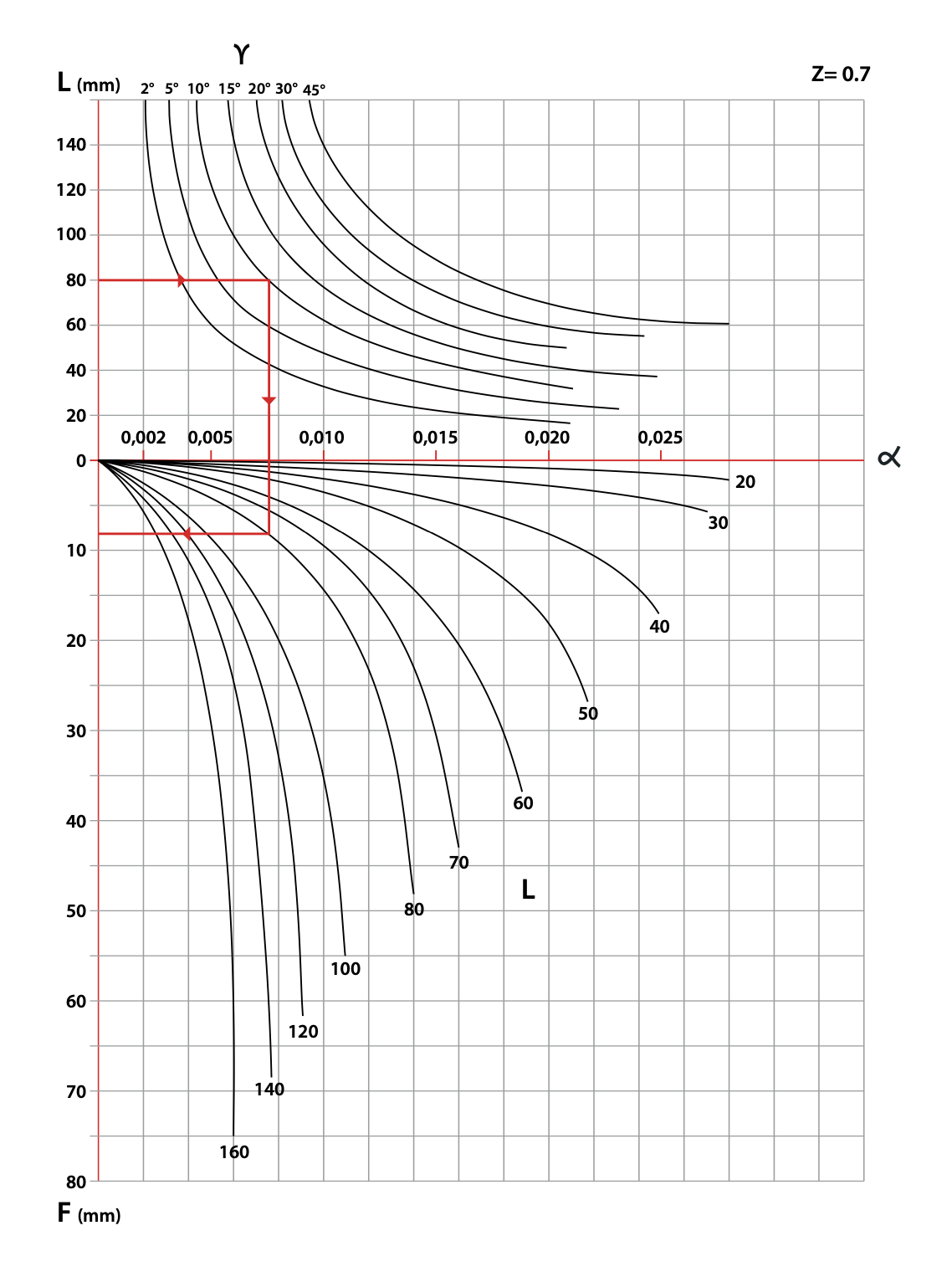

I valori di a, l, d, n sono noti. La determinazione della freccia F richiede tuttavia la soluzione di alcune equazioni abbastanza complesse. Le relazioni tra i parametri sono state riassunte in diagrammi come quello riportato a pag. 11. Il diagramma è riferito ad un coefficiente di attrito tra filamento e superficie metallica Z=0.7, valore abbastanza comune. È stato considerato un acciaio ad alta resistenza. Tramite una diseguaglianza del tipo: f (α , d, F, l, a, n) < = 1 è possibile verificare se l’angolo di lavoro Υ è accettabile. Se la diseguaglianza non è rispettata significa che il carico è troppo grande ed il filamento si rompe in poco tempo (ciclo di fatica).

Occorre in questo caso ridurre Υ. α è un coefficiente di carico del filamento. Tramite il diagramma è possibile ricavare il valore della freccia F, oppure il valore dell’angolo Υ. Per ragioni di efficienza complessiva della spazzola occorre tenere presente che è bene non superare un angolo Υ di 15°.

Siamo a disposizione per fornirvi i necessari dati di progetto.

All’arrivo in magazzino tutti i tipi di filamento vengono accuratamente controllati, soprattutto il diametro. Inoltre viene verificata la loro buona lavorabilità.

I filamenti sintetici in particolare hanno una memoria elastica caratteristica del polimero di cui sono costituiti. Quando una partita di filamento sintetico entra in azienda ne viene controllata anche l’elasticità. Per questo da molti anni abbiamo standardizzato il metodo di misura per mezzo di un apparecchio di prova che carica i campioni di filamento con un peso noto per poi misurare il ritorno elastico dello stesso.

Ogni materiale ha un campo di accettabilità, se il risultato non rientra in questo campo il filamento viene rifiutato. Questo controllo elimina la difettosità dovuta ad una errata fabbricazione dei filamenti, garantendo così una qualità costante nelle forniture di spazzole.

I filamenti vengono spesso analizzati al microscopio per verificarne il livello di finitura. Ad esempio con questo metodo si può controllare la corretta distribuzione delle particelle di SC o AO all’interno del nylon abrasivo. Il metodo è utile anche per verificare la qualità della rasatura di una spazzola, analizzando le estremità dei singoli filamenti.

Domande frequenti

Qual è il vantaggio di usare una spazzola invece di un altro oggetto deformabile?

La caratteristica peculiare della spazzola è che la superficie di lavoro è costituita da milioni di elementi singoli, che sono l’estremità dei singoli filamenti.

Questo conferisce alla spazzola una adattabilità che nessun altro elemento, per quanto deformabile, può avere.

Quanto deve interferire la spazzola sul pezzo da lavorare?

Dipende da vari fattori. In estrema sintesi si può dire che 2 mm è un buon compromesso. L’importante è che i filamenti della spazzola lavorino “di punta” e non sul fianco.

Un mazzetto di filamento si può staccare dal corpo spazzola?

A seconda dei materiali usati e delle dimensioni, esiste un carico limite a trazione che un singolo mazzetto può sopportare. Oltre questo limite il mazzetto si stacca, quindi la spazzola va calcolata a seconda dell’utilizzo. Si può aumentare moltissimo questo limite costruendo spazzole “cucite” o “legate” a mano, dove invece che un elemento di ancoraggio singolo si mette un filo di acciaio continuo.

È possibile che un singolo filamento si sfili dal mazzetto contaminando il prodotto?

Può succedere solo se la spazzola ha un difetto di fabbricazione, come d’altra parte ogni altro tipo di oggetto (ad es. un rullo fatto con lamelle di silicone di cui una è difettosa e si spezza).

Quando è importante che non avvenga alcuna contaminazione è opportuno utilizzare fibre sintetiche (non naturali) con diametro maggiore o uguale a 0.15 mm.

Quale morbidezza o durezza di spazzola posso ottenere?

Praticamente si possono avere tutti i gradi di durezza, da morbidissima a durissima. Infatti la durezza è data dalla combinazione tra il diametro del filamento, la sua lunghezza libera e la densità dei mazzetti.

È possibile avere una spazzola certificata “alimentare”?

Certamente, possiamo fornire certificazioni FDA o FOOD GRADE e rintracciabilità del filamento.

È possibile avere una spazzola certificata ATEX?

Purtroppo no, in quanto è l’insieme macchina + spazzola a dover essere certificata ATEX, non la sola spazzola.

E’ comunque possibile fornire i materiali che il certificatore richiede, ad es. basi conduttive, filamenti conduttivi ecc…

È possibile “rigenerare” una spazzola consumata?

In linea generale è possibile, bisogna però valutare se è economicamente conveniente, e non sempre lo è. Inoltre, nel caso di una spazzola punzonata, è sconsigliabile rigenerare la spazzola più di due volte per non ridurre la tenuta dei mazzetti.