SORT-L

Generalità

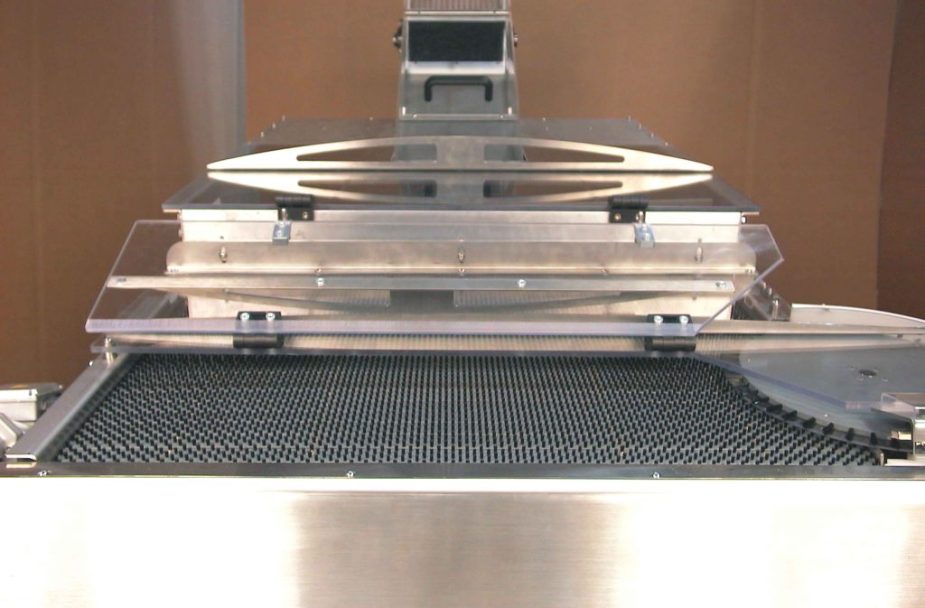

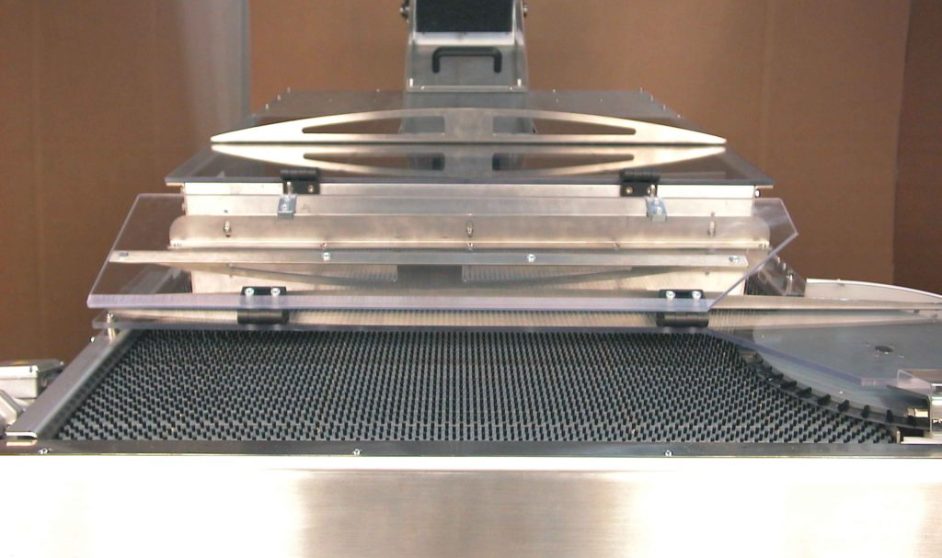

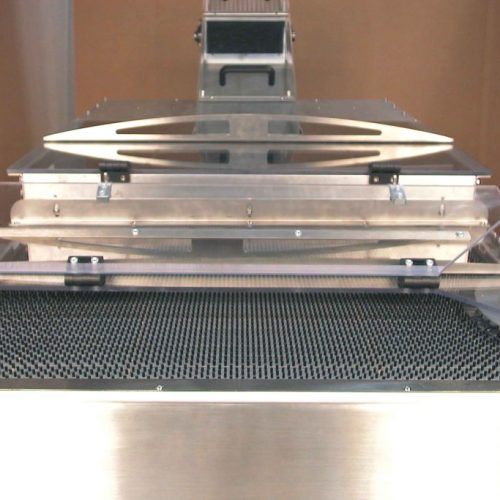

È un orientatore per tappi e oggetti cavi, che sfrutta l’azione di un tappeto setolato mobile e inclinato per orientare gli oggetti.

Utilizza un fronte di selezione piuttosto ampio, per cui è possibile orientare portate rilevanti anche su molte piste. Questo sistema è particolarmente efficiente quando l’oggetto da orientare presenta una superficie liscia in grado di scivolare sul piano di spazzole.

Video e immagini

GALLERIA

Vuoi richiedere un’offerta?

Sei interessato a ricevere maggiori informazioni e ad essere ricontattato da un nostro operatore specializzato?

Richiedi ora la tua offerta

Vuoi richiedere un’offerta?

Sei interessato a ricevere maggiori informazioni e ad essere ricontattato da un nostro operatore specializzato?

Richiedi ora la tua offerta

Domande frequenti

Cosa si intende per “Macchine a spazzole”?

Sono macchine che utilizzano spazzole tecniche nel loro processo produttivo.

Quali sono le principali tipologie di macchine a spazzole?

Depolveratori, orientatori, elevatori, trasportatori.

Quali sono i vantaggi di questo tipo di macchina?

Le spazzole industriali sono caratterizzate da una grande adattabilità alle superfici, da grande flessibilità di utilizzo e varietà di forme e durezza praticamente illimitata. Per questo l’uso di spazzole nelle macchine riesce ad essere molto efficiente in numerosi processi industriali.

In particolare i depolveratori con spazzole sono più efficienti di quelli tradizionali senza contatto, mentre nel caso degli orientatori le spazzole sostituiscono altre tecniche (aria compressa, vibrazione ecc.) riuscendo a trattare i pezzi con bassi consumi energetici, in modo delicato e silenzioso. L’ingombro ridotto è un altro importante vantaggio.

Le spazzole contenute nelle macchine possono causare contaminazione del prodotto per perdita di filamento?

Può succedere solo se la spazzola si danneggia per una causa imprevedibile, come un prodotto difettoso che entra nella macchina e si incastra nella spazzola distruggendola, come d’altra parte può avvenire per ogni altro tipo di particolare presente nella macchina. Va ricordato che lo stesso tipo di spazzola viene correntemente utilizzato in campo farmaceutico ed alimentare senza problemi.

Le vostre macchine sono economicamente competitive?

Parlando dei depolveratori sono sicuramente più economiche rispetto ai principali concorrenti.

Per quanto riguarda gli orientatori sono allineati, ma se si guarda al risparmio energetico e di spazio risultano anch’essi più vantaggiosi.

Ogni quanto tempo occorre sostituire le spazzole?

Non esiste una risposta univoca, dipendendo questo tempo da molti fattori, come velocità del prodotto, materiali, pressione, turni di lavoro, ecc. Come indicazione di larga massima si può dire che un set di spazzole può durare tra uno e due anni, a volte di più.