Spazzole punzonate

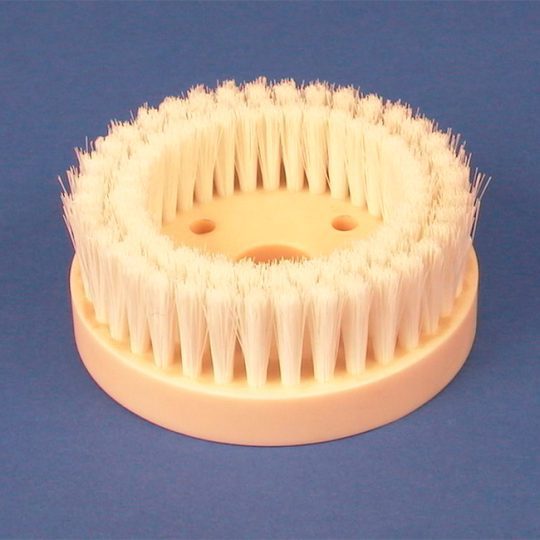

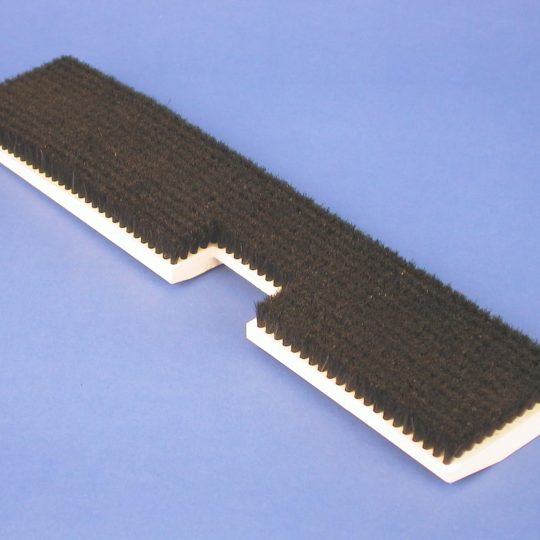

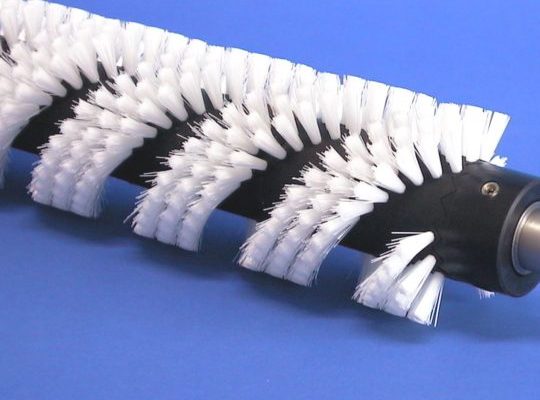

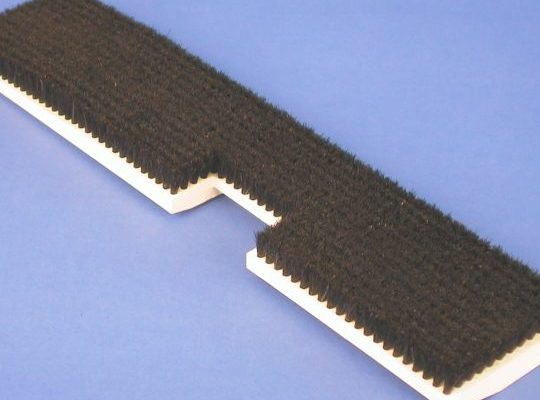

Le spazzole punzonate sono costituite da mazzetti di filamento inseriti sul corpo spazzola per mezzo di un elemento metallico detto “ancora” che si conficca sul fondo del foro preventivamente effettuato. A seconda della forma assunta dalla superficie spazzolante le spazzole punzonate si suddividono in piane, a rullo e frontali. Abbiamo poi spazzole a cinghia (flessibili) e spazzole antistatiche, che eliminano la carica elettrostatica dalle superfici.

Spazzole punzonate

Le spazzole punzonate sono costituite da mazzetti di filamento inseriti sul corpo spazzola per mezzo di un elemento metallico detto “ancora” che si conficca sul fondo del foro preventivamente effettuato. A seconda della forma assunta dalla superficie spazzolante le spazzole punzonate si suddividono in piane, a rullo e frontali. Abbiamo poi spazzole a cinghia (flessibili) e spazzole antistatiche, che eliminano la carica elettrostatica dalle superfici.

Specifiche

Generalità

La caratteristica principale delle spazzole punzonate è la loro versatilità. Infatti, essendo i mazzetti degli elementi indipendenti l’uno dall’altro, essi possono essere disposti in modo da fare assumere alla spazzola sia forme semplici che notevolmente complesse. Per questo motivo le spazzole punzonate sono particolarmente indicate per essere costruite in tutte le forme e dimensioni, e sono insostituibili quando il supporto abbia anche una funzione meccanica nell’impianto in cui andranno installate. Per questi motivi le spazzole punzonate sono quelle che garantiscono la maggiore precisione dimensionale e sostanzialmente la massima qualità di esecuzione.

Il diametro dei mazzetti è di fondamentale importanza nel progetto della spazzola tecnica.

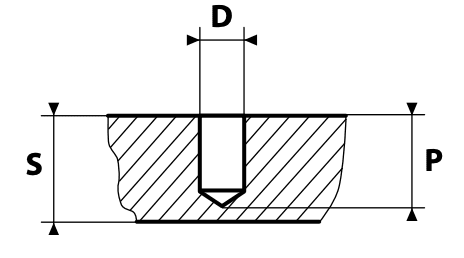

Anche da esso, infatti, dipenderà il rendimento complessivo in fase di lavoro. Esiste una relazione tra il diametro D dei mazzetti e la profondità di foratura P. A sua volta la profondità P è limitata dallo spessore S del supporto.

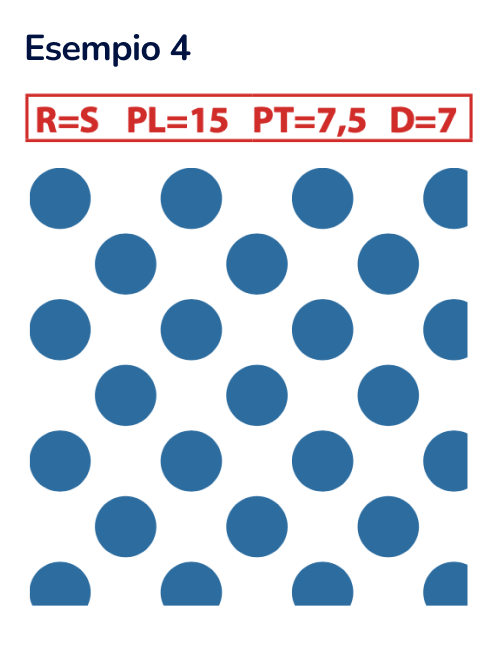

In Tabella sono riportati il possibile diametro dei mazzetti ed i relativi valori di P e S. Quando si hanno a disposizione supporti di grosso spessore la scelta del diametro dei mazzetti è determinata da motivazioni non dimensionali. Ad esempio ci si orienterà su mazzetti grandi per spazzole sottoposte a grosso sforzo (e che quindi necessitano di un robusto ancoraggio). Oppure si preferiranno mazzetti piccoli per ottenere una spazzola di elevata densità o molto morbida.

| D (mm) | 2.0 | 2.5 | 3.0 | 3.5 | 4.0 | 4.5 | 5.0 | 5.5 | 6.0 | 6.5 | 7.0 | 7.5 | 8.0 | 9.0 | 10.0 | 11.0 | 12.0 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| P (mm) | 5.0 | 5.0 | 6.0 | 7.0 | 8.0 | 9.0 | 9.5 | 10.0 | 11.0 | 12.0 | 12.5 | 13.0 | 14.0 | 15.5 | 17.0 | 18.5 | 20.0 |

| S≥ (mm) | 6.0 | 6.0 | 7.0 | 8.0 | 9.0 | 10.0 | 11.0 | 12.0 | 13.0 | 14.0 | 15.0 | 15.0 | 16.0 | 18.0 | 20.0 | 22.0 | 24.0 |

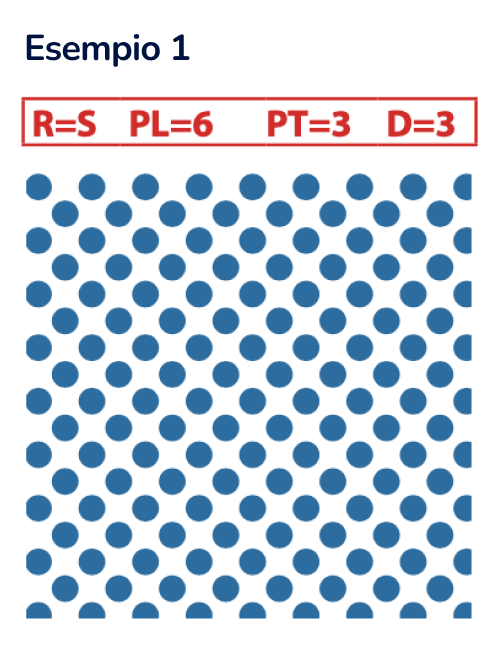

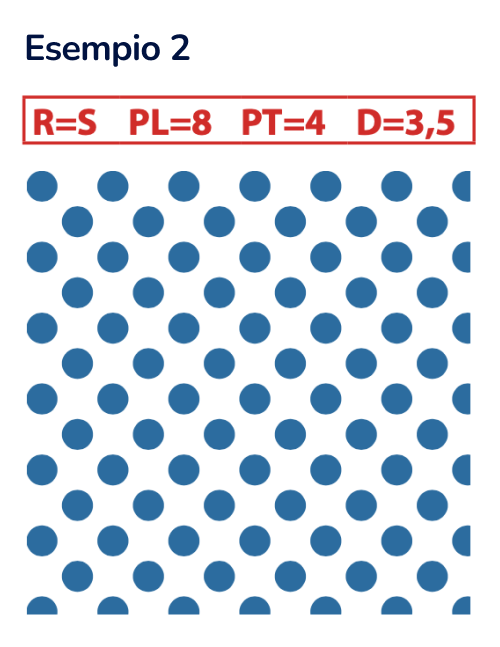

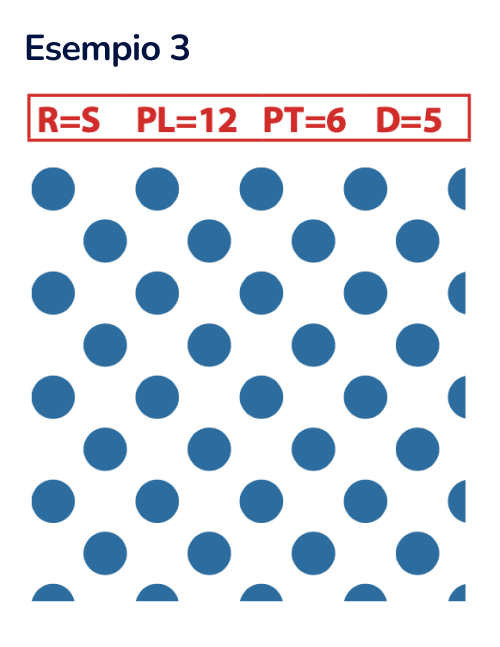

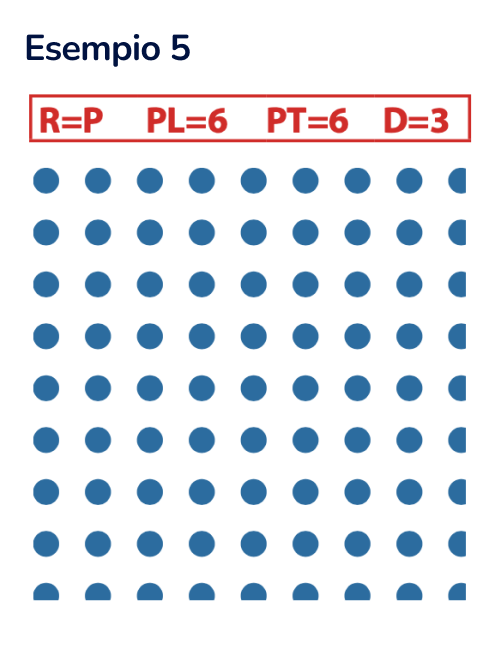

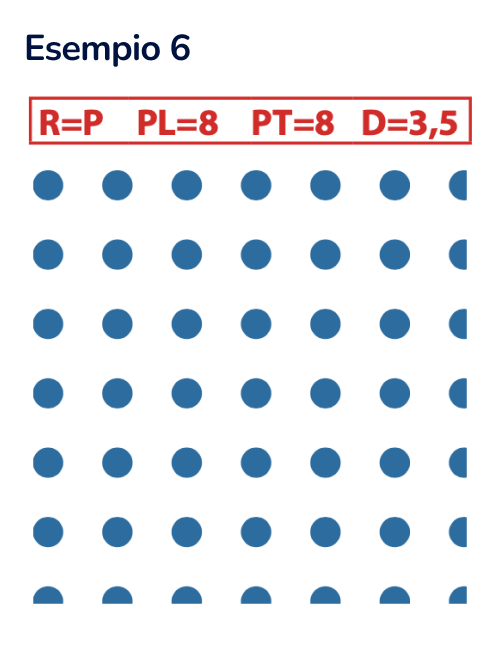

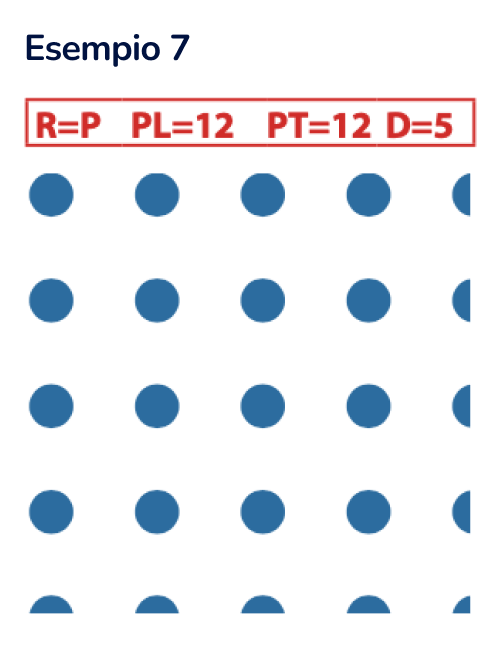

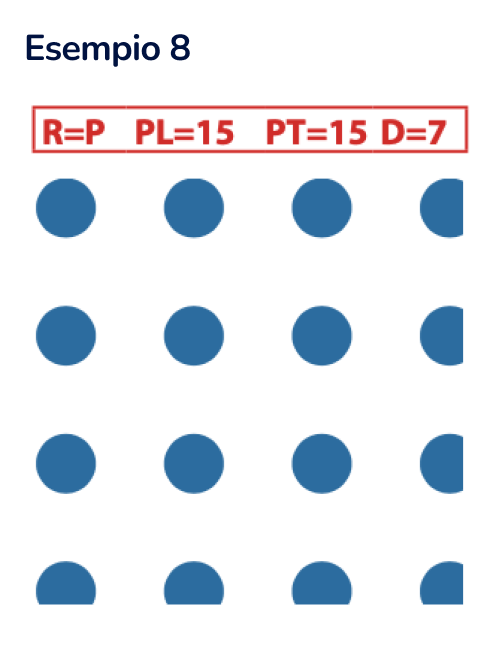

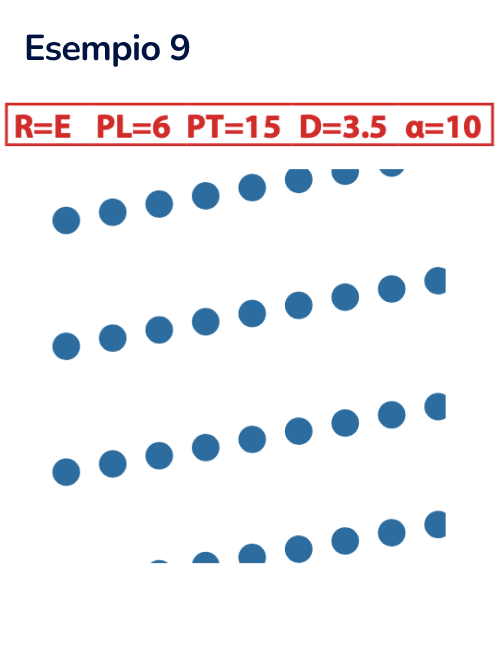

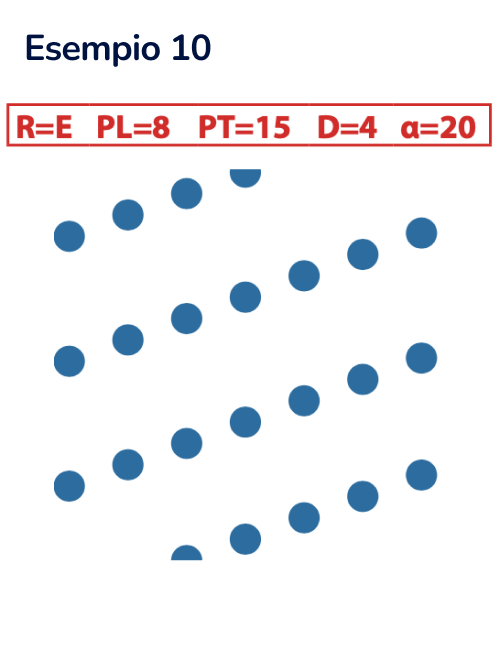

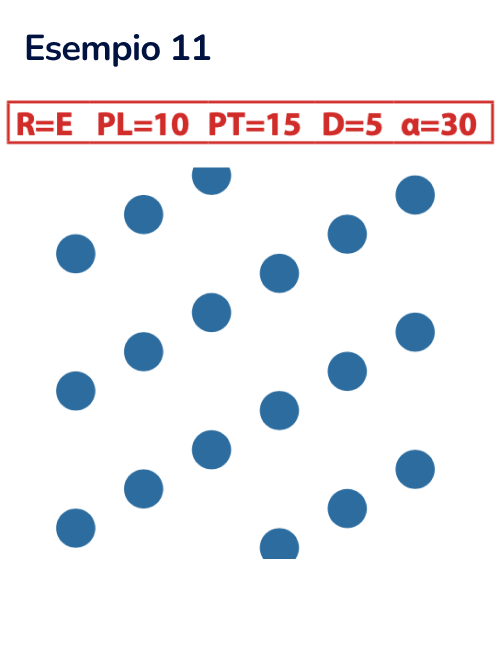

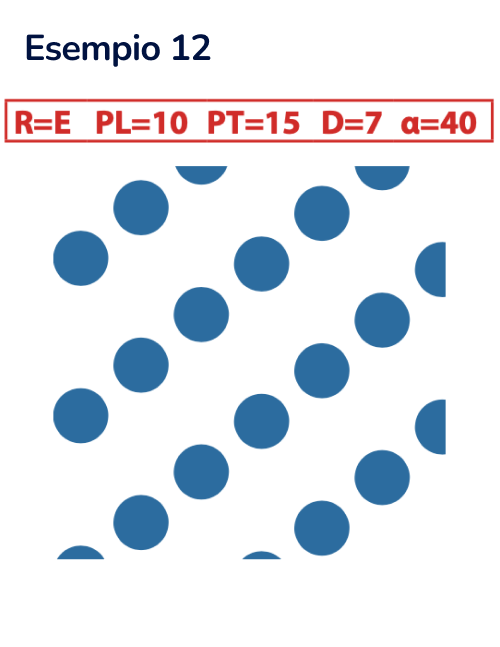

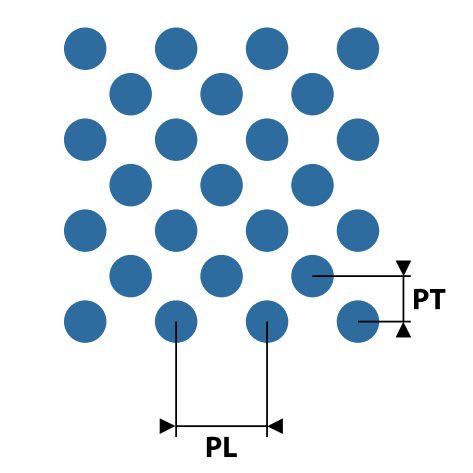

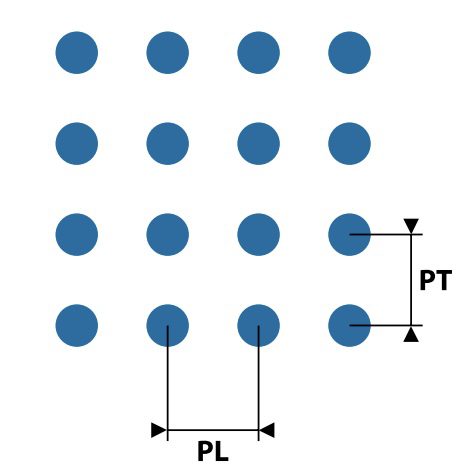

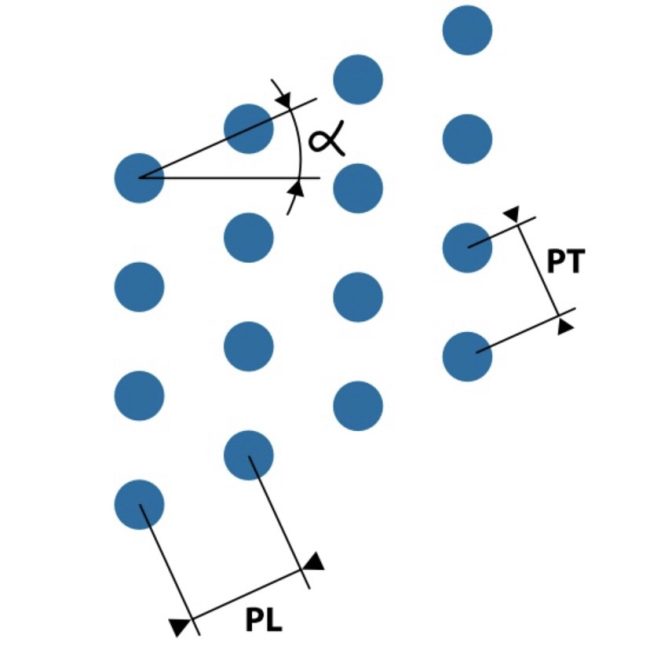

I mazzetti possono essere disposti in qualunque modo sul corpo spazzola. Quando la disposizione assume una caratteristica regolare, prende il nome di RETICOLO. Naturalmente vi possono essere infiniti tipi di reticolo, tuttavia i più utilizzati sono quelli sotto rappresentati.

RETICOLO SFALSATO

è quello più utilizzato e trova impiego nei seguenti casi:

- superficie spazzolante particolarmente densa;

- superficie spazzolante estremamente uniforme.

RETICOLO PARALLELO

viene utilizzato nei seguenti casi:

- la spazzola deve scaricare facilmente i detriti senza intasarsi;

- tra i mazzetti devono scorrere parti meccaniche;

- la spazzola deve essere tagliata in parti dall’utilizzatore.

RETICOLO ELICOIDALE (solo rulli)

viene utilizzato per i rulli nei seguenti casi:

- la spazzola deve convogliare da un lato il materiale trattato;

- la spazzola deve agire sulla superficie da trattare con gradualità e delicatezza;

- deve essere evitata ogni possibilità di rigatura su superfici delicate.

L’elica può essere formata da vari principi aventi ognuno più file di mazzetti.

Il nostro ufficio tecnico è a vostra disposizione per consigliare la più idonea disposizione dei mazzetti a seconda dell’utilizzo della spazzola.

Affinché possiate avere un’idea ben precisa di ciò che vi proponiamo o per fare voi stessi una scelta, riteniamo utile riportare lo schema dei reticoli più utilizzati nella pratica.

Resta inteso che sono possibili tutte le soluzioni intermedie ed anche quelle più estreme.

Tipologie di spazzole punzonate:

Vuoi richiedere un’offerta?

Seleziona per quale tipo di spazzola vuoi richiedere maggiori informazioni

Vuoi richiedere un’offerta?

Seleziona per quale tipo di spazzola vuoi richiedere maggiori informazioni

Vuoi richiedere un’offerta?

Seleziona per quale tipo di spazzola vuoi richiedere maggiori informazioni