Cleaning products during an industrial process: Dust collectors

Cleaning products during an industrial process: Dust collectors

What are dust collectors?

Machines capable of removing dust and other residues from product surfaces during industrial processes.

Why is it important to have clean products?

- Many modern production processes cannot tolerate dust and other residues on the surface of products

- Dust and other particles can damage or contaminate end products. This causes a high level of production waste, higher costs, more non-conforming returns and, consequently, lower customer satisfaction

Different ways to clean your products

Dust collectors can be divided into two main types: Contact or non-contact.

- Non-contact means that the dust collector does not physically touch the products to be cleaned

- With contact means that the dust collector physically touches the products to be cleaned through a brush

Intuitively, contact dedusting guarantees better results with significantly deeper and more precise cleaning. For this reason, non-contact dedusting is only recommended when the product to be cleaned is particularly fragile and delicate.

Non-contact cleaning

- PRO: suitable for particularly delicate products, which could be damaged if touched even gently

- CON: Some types of dust require contact through mechanical action to be removed. In this case, the non-contact cleaning method would be ineffective

Contact cleaning

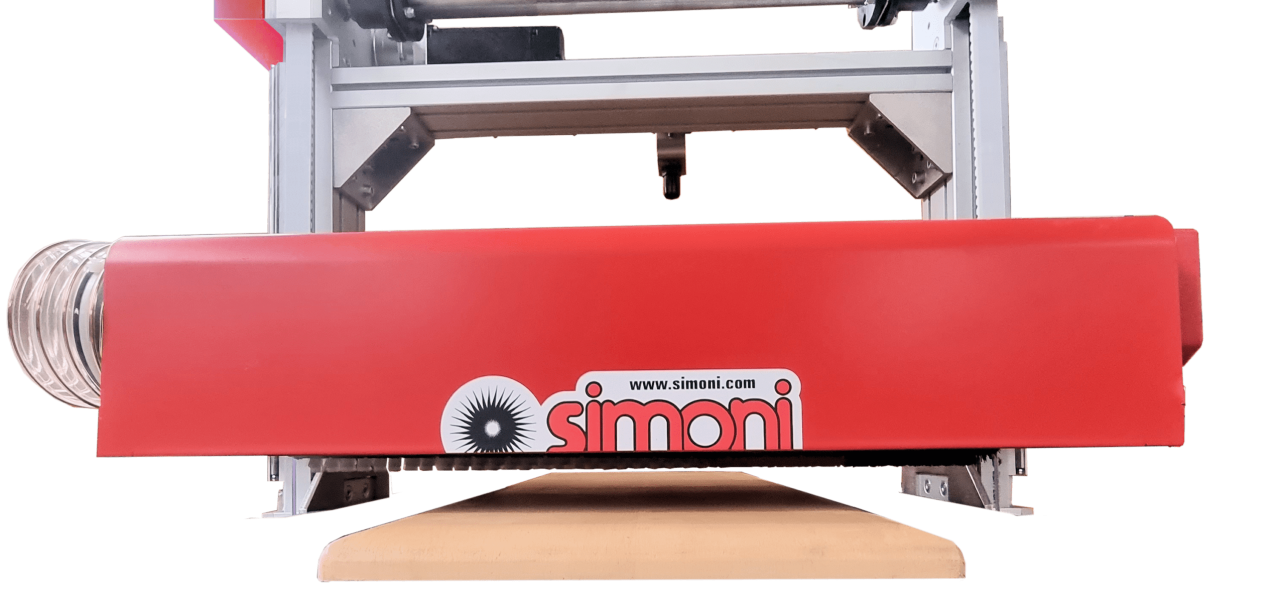

Brushes + ionised (compressed or ventilated) and simultaneously sucked air.

Simoni’s ‘contact’ cleaning method also provides significant benefits over the competition:

- Dry cleaning method. It is therefore also suitable for moisture-sensitive products (e.g. paper/cardboard products)

- High degree of cleanliness

- Highly adaptable to surfaces

- Low operating and maintenance costs

- No risk due to human error, as everything is fully automatic. Our dust collectors can work 24 hours a day, 7 days a week, without the need for operators

Our dust collectors as a result of a long history

Our dust collectors are the result of almost 200 years of continuous evolution, which began in 1830 as manufacturers of industrial brushes. We were able to use our deep experience and long tradition in industrial brushes to create the most efficient and flexible dust collectors on the market, as they are based on brush technology.