Spazzole punzonate frontali

Spazzole punzonate frontali

Generalità

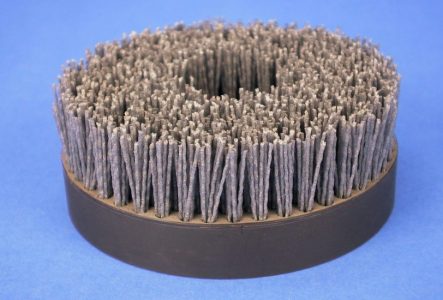

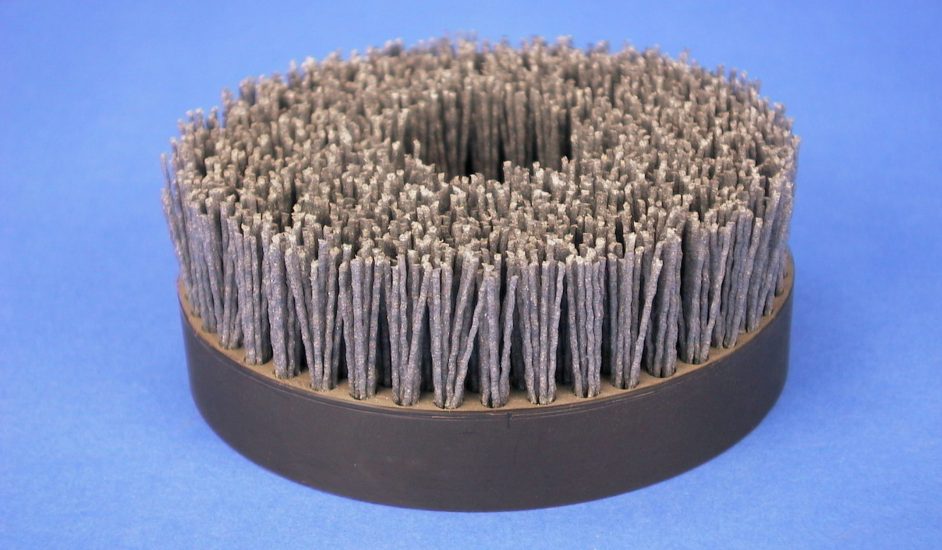

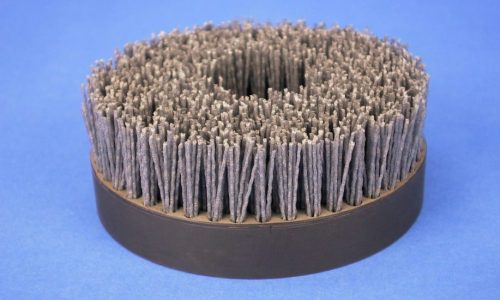

Sono spazzole con la superficie di lavoro perpendicolare al loro asse di rotazione, indicate pertanto nella lavorazione di superfici piane, e sono motorizzate. La superficie di lavoro può essere continua o a settori.

Le spazzole frontali sono utilizzate per :

- Pulizia meccanizzata di superfici piane

- Levigatura meccanizzata di superfici piane

- Sbavatura di parti meccaniche, come ruote dentate, ecc…

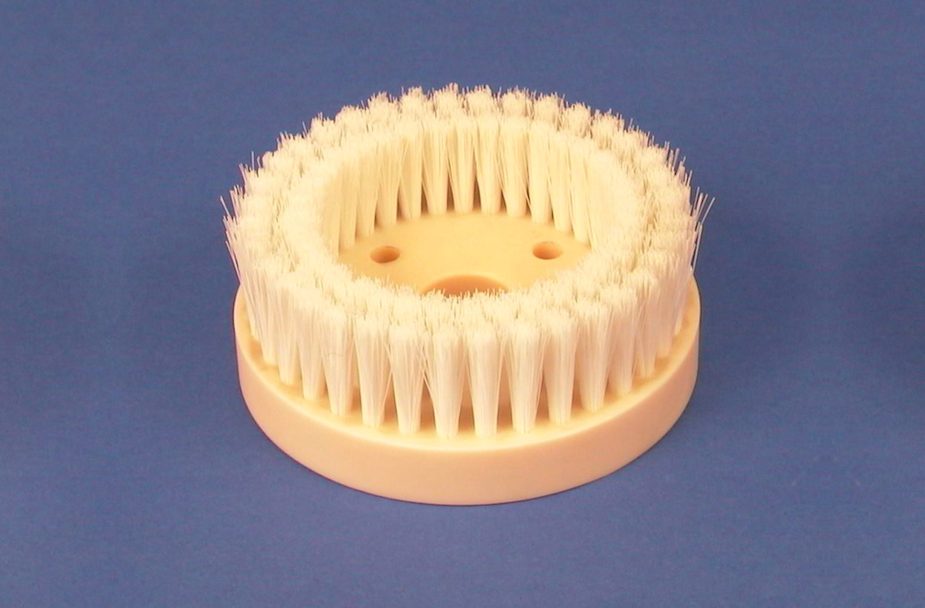

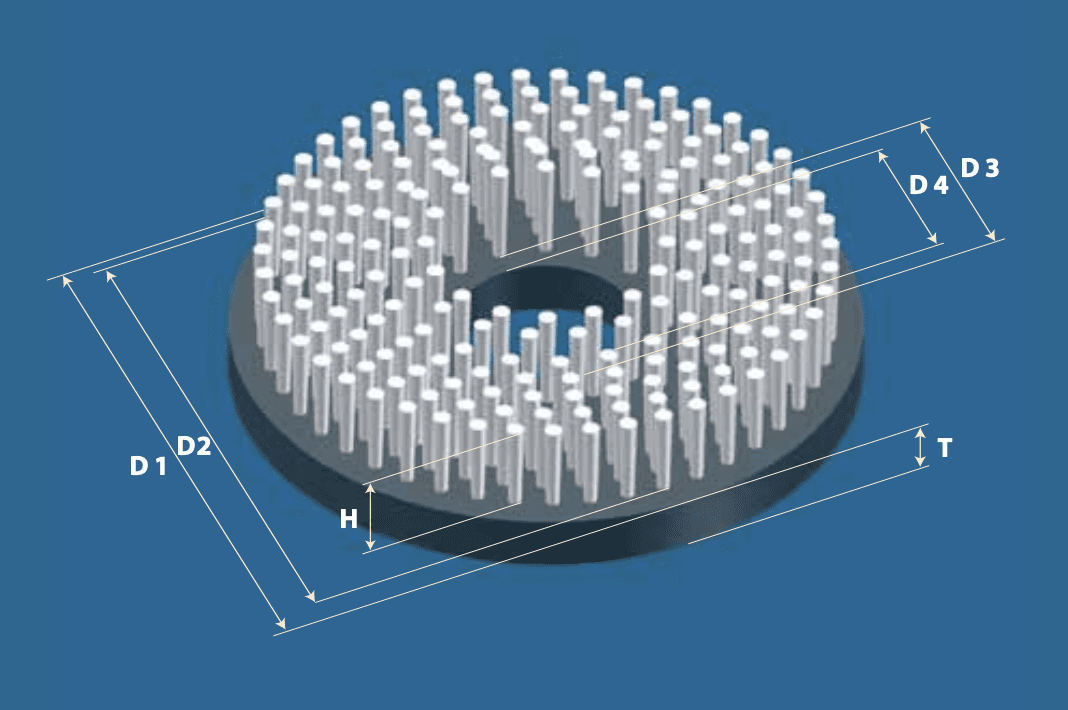

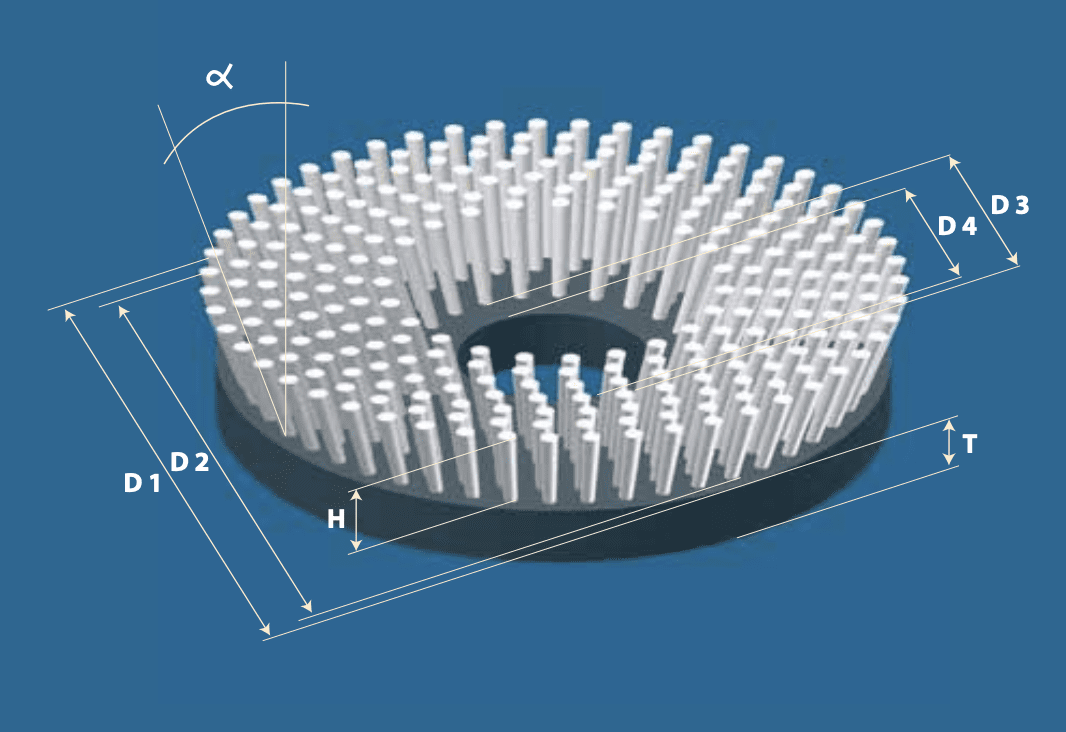

I mazzetti sono generalmente diritti, ma è possibile dare loro un’inclinazione come nella Figura a destra.

Ciò può essere utile per aumentare la superficie di lavoro a parità di ingombro del corpo spazzola. L’angolo α non può generalmente superare i 15°.

Per quanto riguarda la motorizzazione, il caso della spazzola frontale è il più gravoso.

Infatti, rispetto per esempio ad un rullo di pari lunghezza, qui tutti i mazzetti sono contemporaneamente in presa. È possibile dimensionare il motore utilizzando la seguente formula: P = (n x N x F1 x R) / 1000 dove: P è la potenza richiesta al motore [KW] N è il numero dei mazzetti R è il raggio della spazzola [m] n è la velocità della spazzola [rpm] F1 è la forza tangenziale massima applicabile al singolo mazzetto [Kg] ed è un dato sperimentale. La potenza varia da 0 a P a seconda della pressione applicata alla spazzola.

Il corpo spazzola è generalmente sintetico, ma anche in alluminio in caso di tolleranze sulla planarità.

Normalmente queste spazzole sono montate su albero motorizzato. Per questo scopo si può realizzare un’incameratura per il contenimento del dado di serraggio, ed una sede per linguetta per il trascinamento. Il corpo spazzola può avere anche forme particolari per il montaggio e la movimentazione su macchine automatiche. Generalmente viene ottenuto con lavorazione meccanica, ma quando presenta forme complesse può essere prodotto per stampaggio 3D o, con quantità elevate, per stampaggio a iniezione.

Video e immagini

GALLERIA

Vuoi richiedere un’offerta?

Sei interessato a ricevere maggiori informazioni e ad essere ricontattato da un nostro operatore specializzato?

Richiedi ora la tua offerta

Vuoi richiedere un’offerta?

Sei interessato a ricevere maggiori informazioni e ad essere ricontattato da un nostro operatore specializzato?

Richiedi ora la tua offerta

Domande frequenti

Qual è il vantaggio di usare una spazzola invece di un altro oggetto deformabile?

La caratteristica peculiare della spazzola è che la superficie di lavoro è costituita da milioni di elementi singoli, che sono l’estremità dei singoli filamenti.

Questo conferisce alla spazzola una adattabilità che nessun altro elemento, per quanto deformabile, può avere.

Quanto deve interferire la spazzola sul pezzo da lavorare?

Dipende da vari fattori. In estrema sintesi si può dire che 2 mm è un buon compromesso. L’importante è che i filamenti della spazzola lavorino “di punta” e non sul fianco.

Un mazzetto di filamento si può staccare dal corpo spazzola?

A seconda dei materiali usati e delle dimensioni, esiste un carico limite a trazione che un singolo mazzetto può sopportare.

Oltre questo limite il mazzetto si stacca, quindi la spazzola va calcolata a seconda dell’utilizzo. Si può aumentare moltissimo questo limite costruendo spazzole “cucite” o “legate” a mano, dove invece che un elemento di ancoraggio singolo si mette un filo di acciaio continuo.

È più economica una spazzola punzonata o una strip?

Non c’è una risposta univoca. Parlando ad es.di spazzole cilindriche la spazzola strip è in genere più economica quando le dimensioni sono importanti (es.oltre il metro di lunghezza). Per piccole dimensioni le spazzole punzonate sono sicuramente più adatte e convenienti.

È possibile che un singolo filamento si sfili dal mazzetto contaminando il prodotto?

Può succedere solo se la spazzola ha un difetto di fabbricazione, come d’altra parte ogni altro tipo di oggetto (ad es. un rullo fatto con lamelle di silicone di cui una è difettosa e si spezza).

Quando è importante che non avvenga alcuna contaminazione è opportuno utilizzare fibre sintetiche (non naturali) con diametro maggiore o uguale a 0.15 mm.

Quale morbidezza o durezza di spazzola posso ottenere?

Praticamente si possono avere tutti i gradi di durezza, da morbidissima a durissima. Infatti la durezza è data dalla combinazione tra il diametro del filamento, la sua lunghezza libera e la densità dei mazzetti.

È possibile avere una spazzola certificata “alimentare”?

Certamente, possiamo fornire certificazioni FDA o FOOD GRADE e rintracciabilità del filamento.

È possibile avere una spazzola certificata ATEX?

Purtroppo no, in quanto è l’insieme macchina + spazzola a dover essere certificata ATEX, non la sola spazzola.

E’ comunque possibile fornire i materiali che il certificatore richiede, ad es. basi conduttive, filamenti conduttivi ecc…

È possibile “rigenerare” una spazzola consumata?

In linea generale è possibile, bisogna però valutare se è economicamente conveniente, e non sempre lo è. Inoltre, nel caso di una spazzola punzonata, è sconsigliabile rigenerare la spazzola più di due volte per non ridurre la tenuta dei mazzetti.