Punched brushes

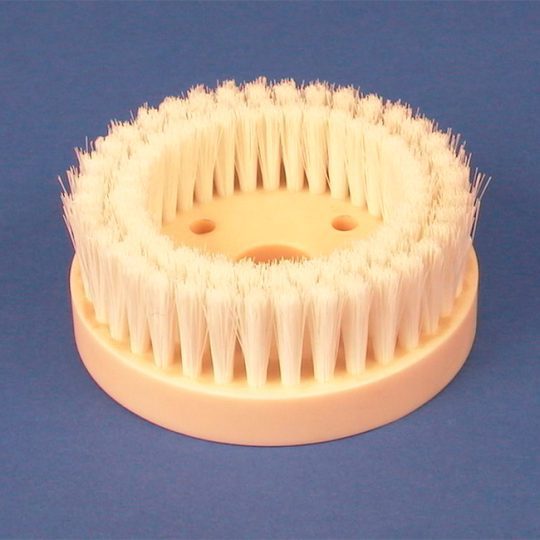

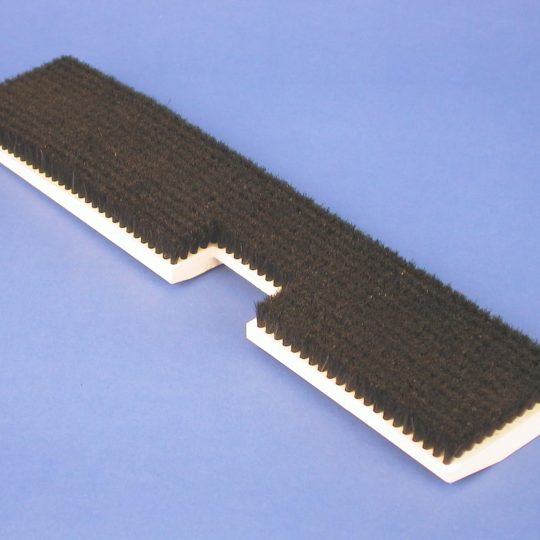

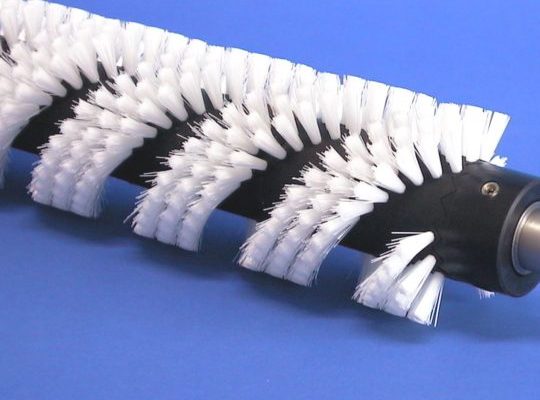

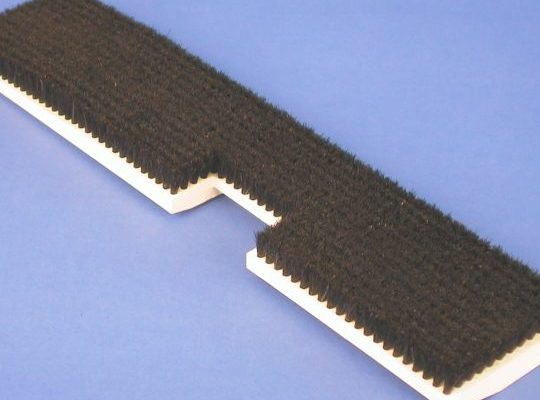

Punched brushes consist of bundles of filament inserted on the brush body by means of a metal element known as an ‘anchor’ that sticks to the bottom of the hole previously made. Depending on the shape of the brushing surface, punched brushes are subdivided into flat, roller and face brushes. We also have belt brushes (flexible) and antistatic brushes, which remove electrostatic charge from surfaces.

Punched brushes

Punched brushes consist of bundles of filament inserted on the brush body by means of a metal element known as an ‘anchor’ that sticks to the bottom of the hole previously made. Depending on the shape of the brushing surface, punched brushes are subdivided into flat, roller and face brushes. We also have belt brushes (flexible) and antistatic brushes, which remove electrostatic charge from surfaces.

Specifications

Generalities

The main feature of punched brushes is their versatility. In addition, since the bundles are independent of each other, they can be arranged in such a way as to make the brush take on both simple and highly complex shapes. For this reason, punched brushes are particularly suited to be constructed in all shapes and sizes, and are irreplaceable when the holder also has a mechanical function in the system in which they are to be installed. For these reasons, punched brushes are those that guarantee the highest dimensional accuracy and basically the highest quality of execution.

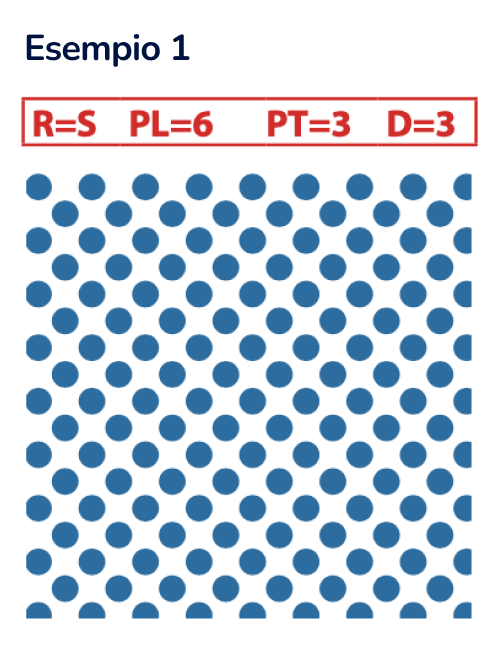

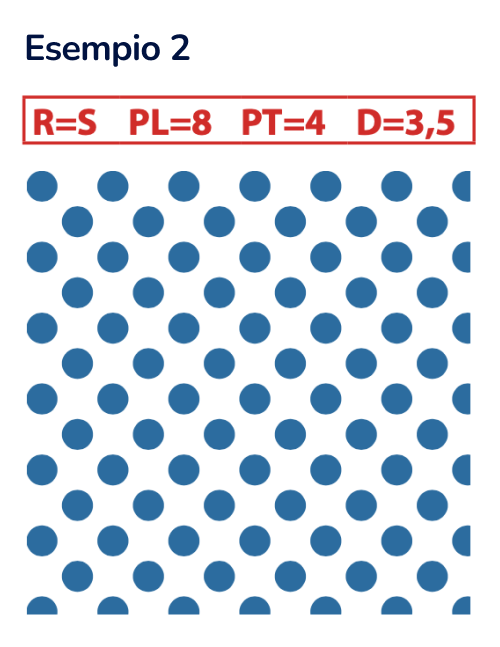

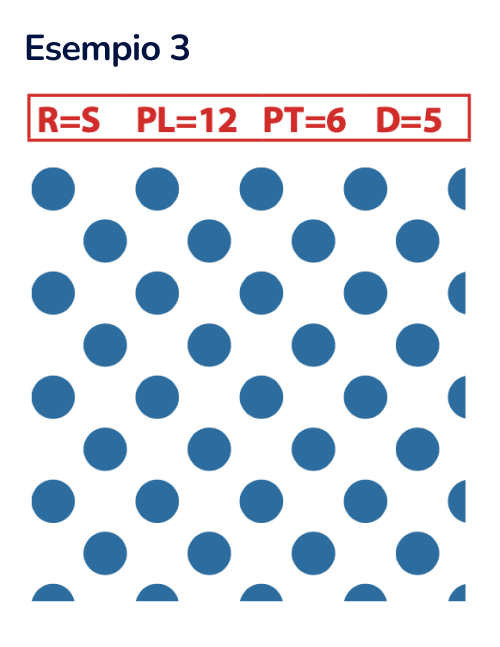

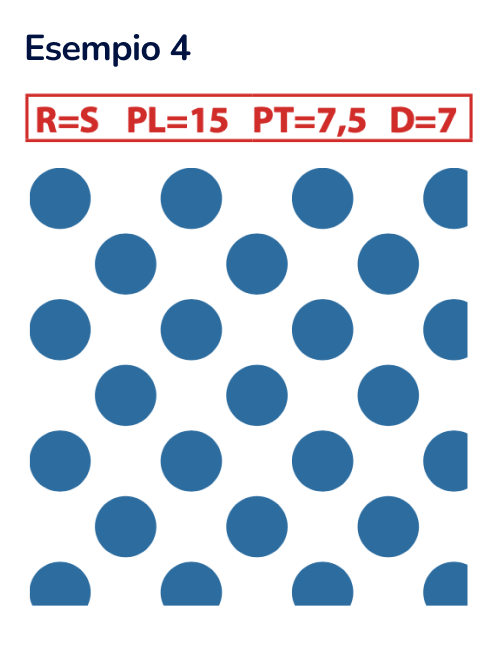

The diameter of the bundles is of paramount importance in the design of the technical brush.

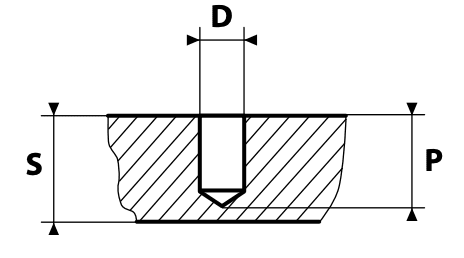

The overall performance at work will also depend on it. There is a relationship between the diameter D of the bundles and the drilling depth P. In turn, the depth P is limited by the thickness S of the substrate.

The table shows the possible bundle diameters and the associated P and S values. When thicker supports are available, the choice of bundle diameter is determined by non-dimensional reasons. For example, one would opt for large bundles for brushes that are subjected to great stress (and therefore require a strong anchorage). Or small bunches are preferred to obtain a high density or very soft brush.

| D (mm) | 2.0 | 2.5 | 3.0 | 3.5 | 4.0 | 4.5 | 5.0 | 5.5 | 6.0 | 6.5 | 7.0 | 7.5 | 8.0 | 9.0 | 10.0 | 11.0 | 12.0 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| P (mm) | 5.0 | 5.0 | 6.0 | 7.0 | 8.0 | 9.0 | 9.5 | 10.0 | 11.0 | 12.0 | 12.5 | 13.0 | 14.0 | 15.5 | 17.0 | 18.5 | 20.0 |

| S≥ (mm) | 6.0 | 6.0 | 7.0 | 8.0 | 9.0 | 10.0 | 11.0 | 12.0 | 13.0 | 14.0 | 15.0 | 15.0 | 16.0 | 18.0 | 20.0 | 22.0 | 24.0 |

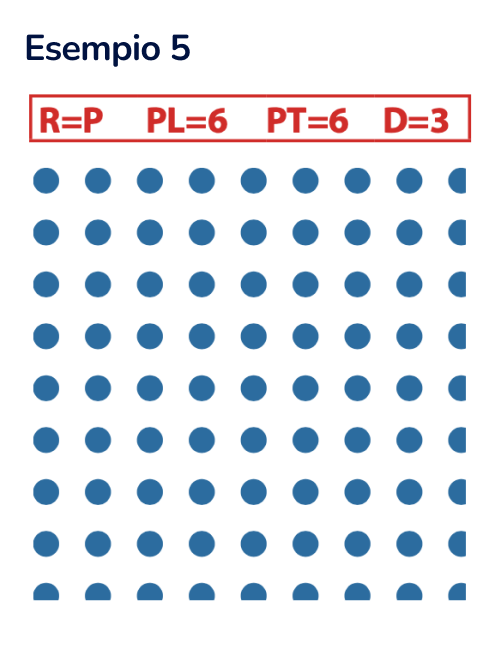

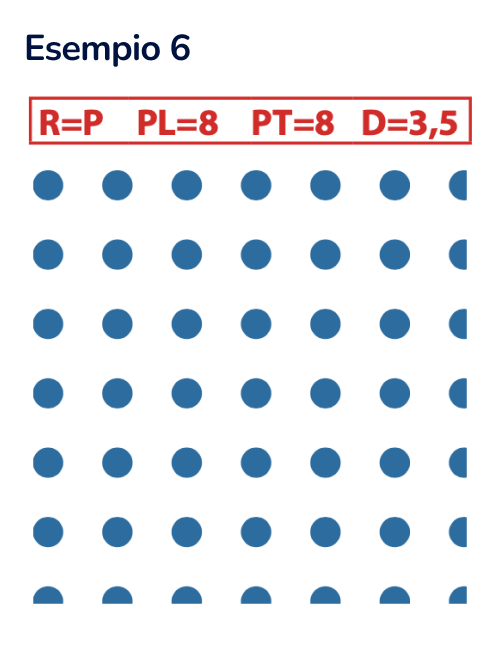

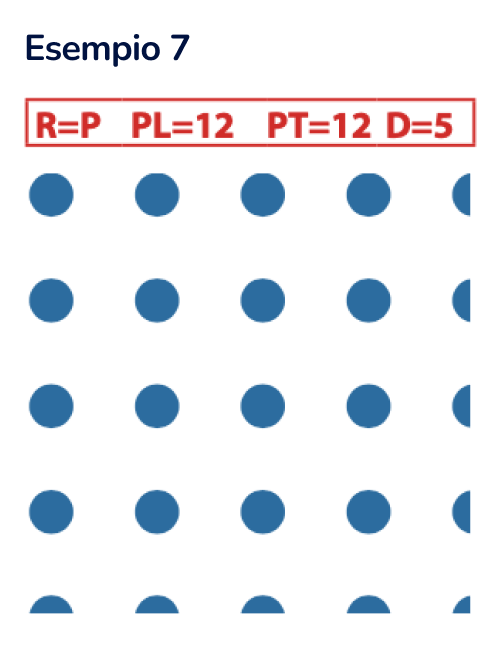

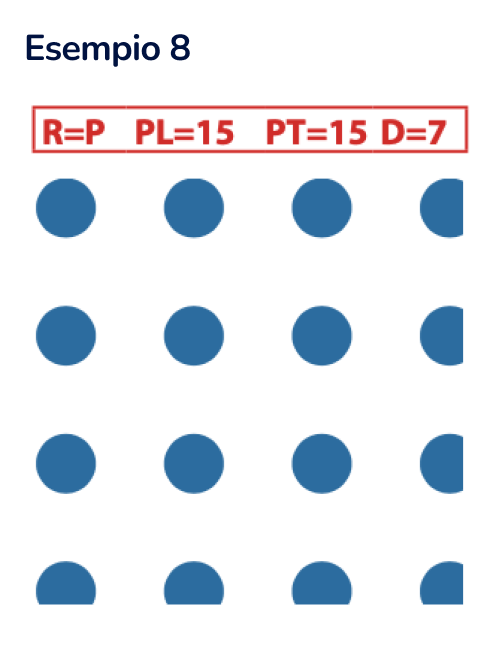

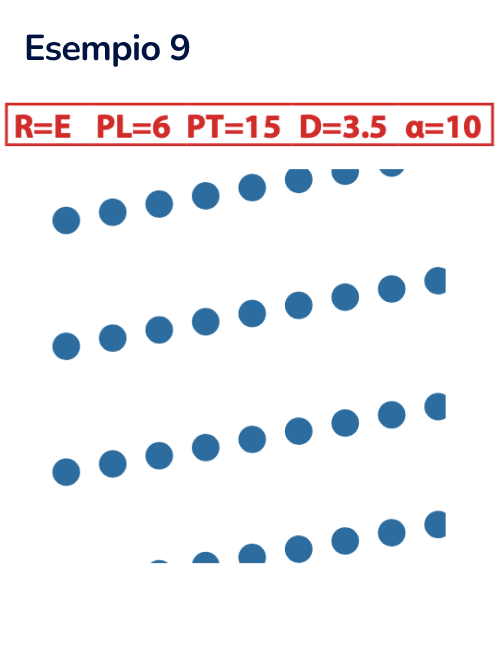

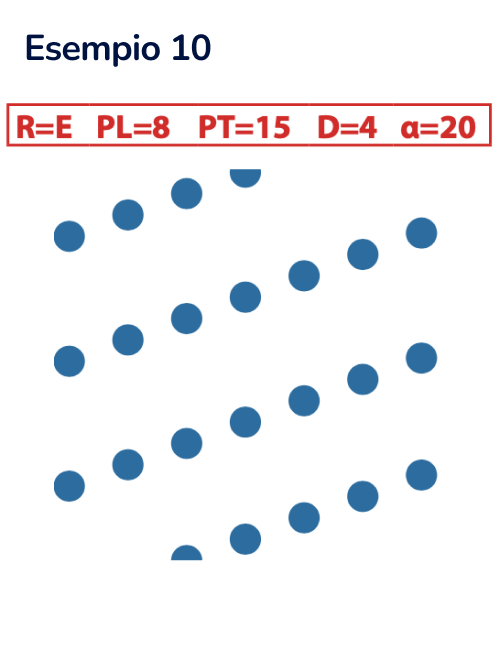

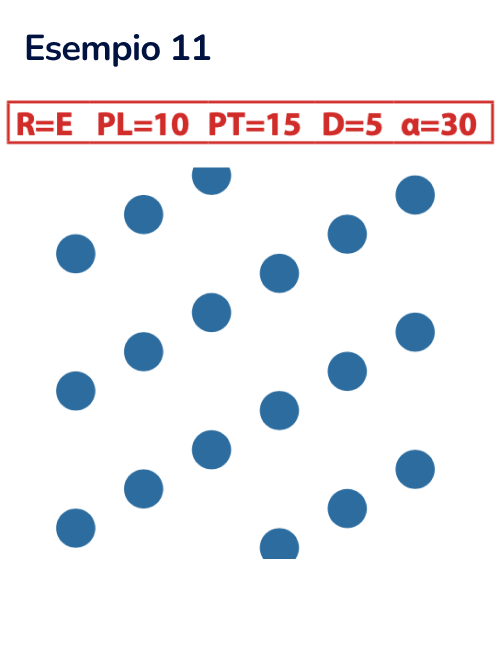

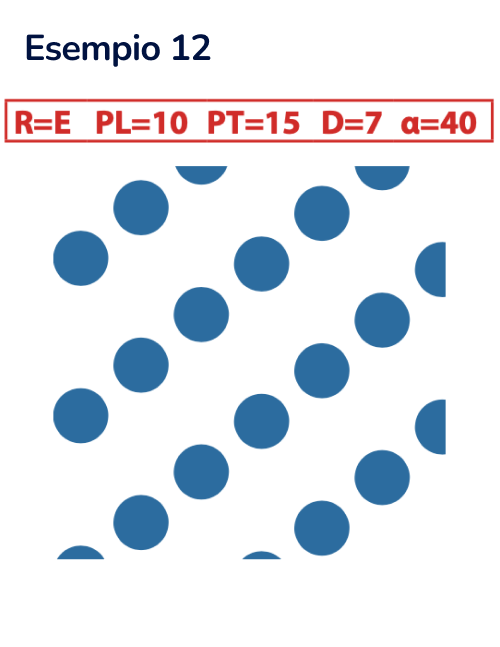

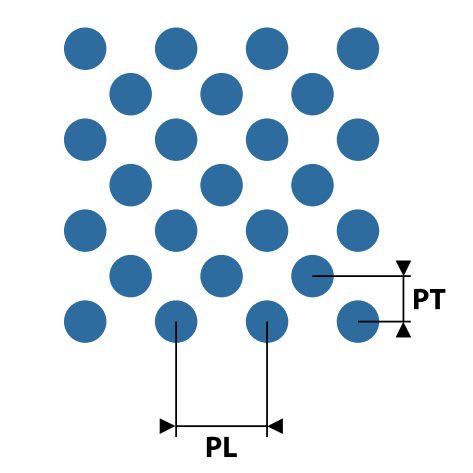

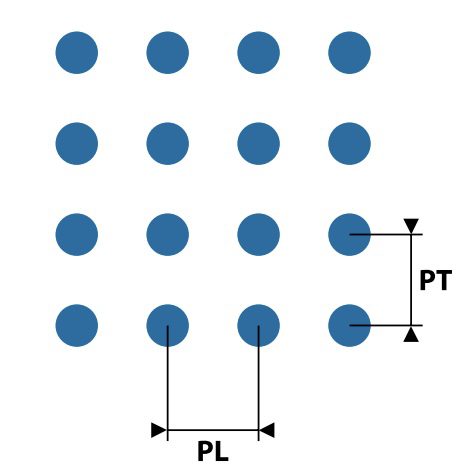

The bundles can be arranged in any way on the brush body. When the arrangement takes on a regular characteristic, it is called a NETWORK. Of course, there can be infinite types of lattice, but the most commonly used are those shown below.

OFFSET GRID

is the most commonly used and is used in the following cases:

- particularly dense brushing surface;

- extremely even brushing surface.

PARALLEL GRID

is used in the following cases:

- the brush must easily discharge debris without clogging;

- mechanical parts must run between the bundles;

- the brush must be cut into parts by the user.

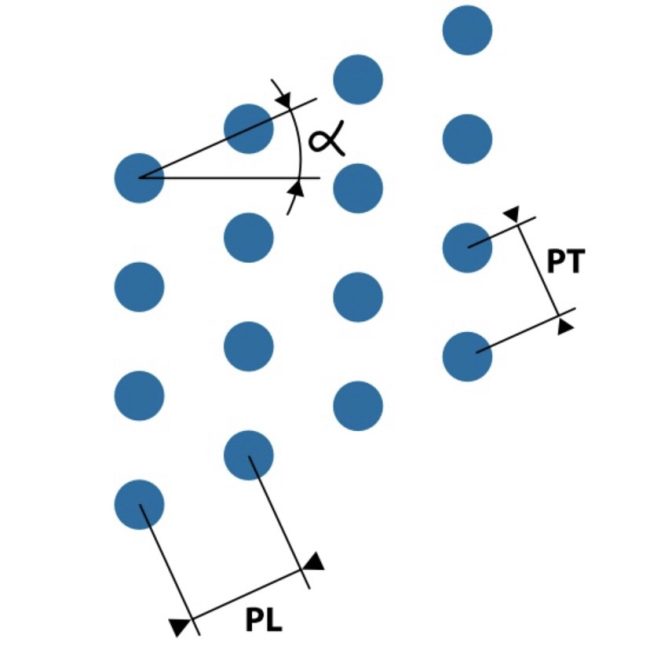

HELICOIDAL GRID (rollers only)

is used for rollers in the following cases

- the brush must convey the treated material to one side;

- the brush must act on the surface to be treated gradually and gently;

- any possibility of scoring on delicate surfaces must be avoided.

The helix can consist of several principles, each having several rows of bundles.

Our technical department is at your disposal to advise on the most suitable bundle arrangement depending on the use of the brush.

In order for you to have a clear idea of what we are proposing, or to make a choice yourself, we consider it useful to list the most commonly used grids in practice.

It is understood that all intermediate and even extreme solutions are possible.

Types of punched brushes:

Do you want to request an offer?

Please select for which type of brush you would like to request more information

Do you want to request an offer?

Please select for which type of brush you would like to request more information

Do you want to request an offer?

Please select for which type of brush you would like to request more information