Flat punched brushes

Flat punched brushes

Generalities

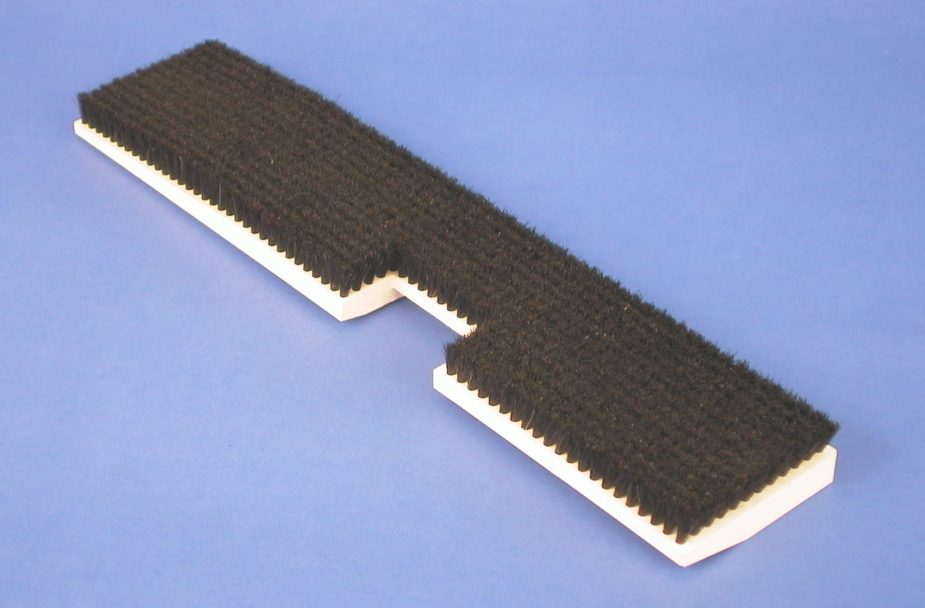

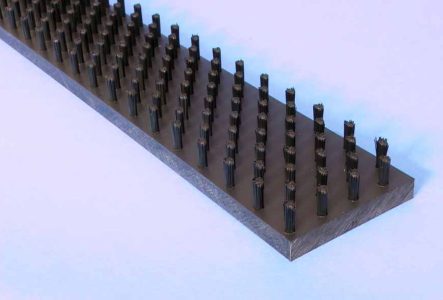

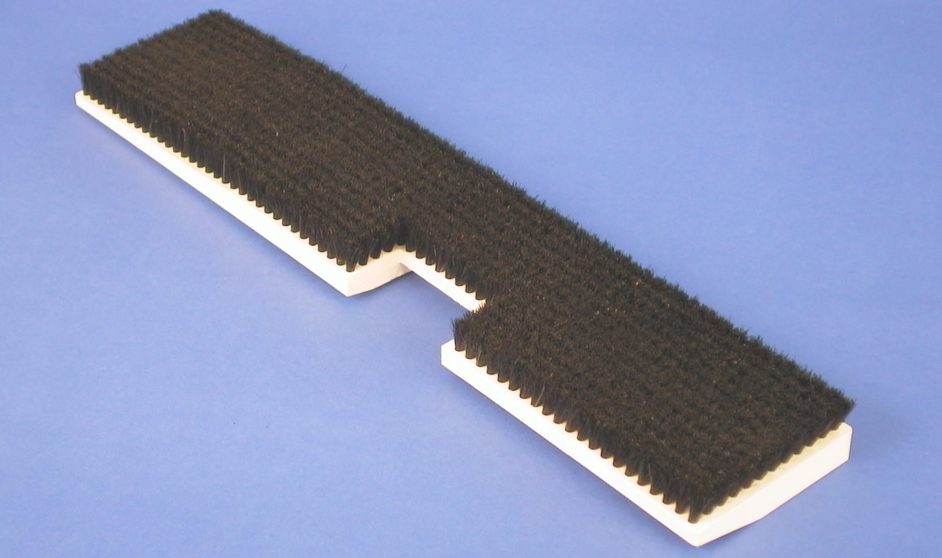

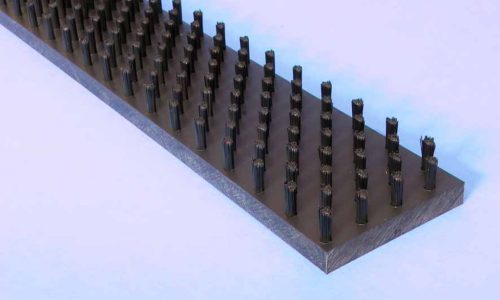

They are generally mounted on fixed parts of machines, sometimes they can also be installed on cylindrical drums to form a roller or on slides with reciprocating motion. The work surface can be continuous, sectoral or shaped according to customer design. In these brushes, flatness is often crucial, both in terms of the brush body and the shaving, which defines the working surface.

Flat brushes are used for:

- Precision brushes

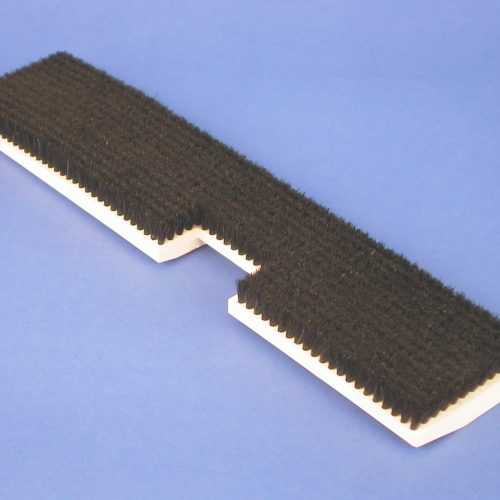

- Brushes with complex geometric shapes

- Transport plans

- Guides for sliding products

- Complex shape barriers for chips and dust

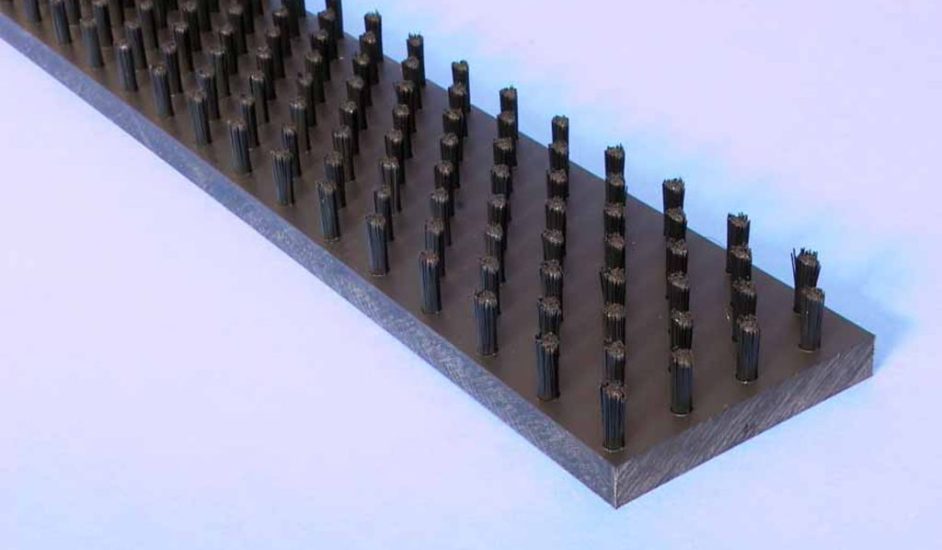

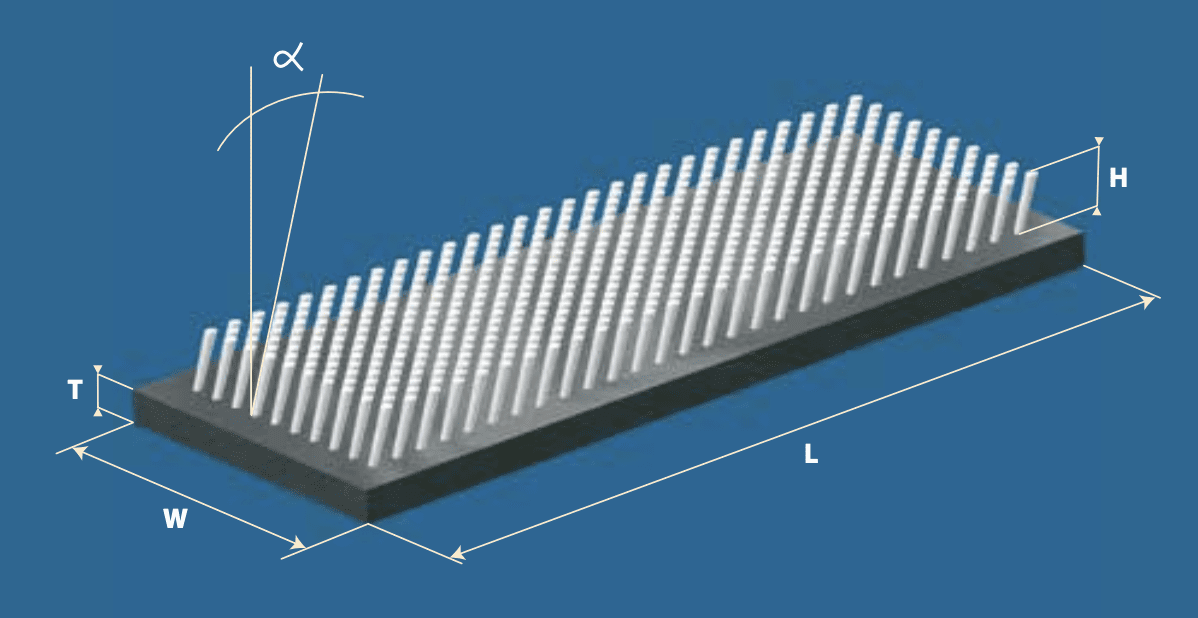

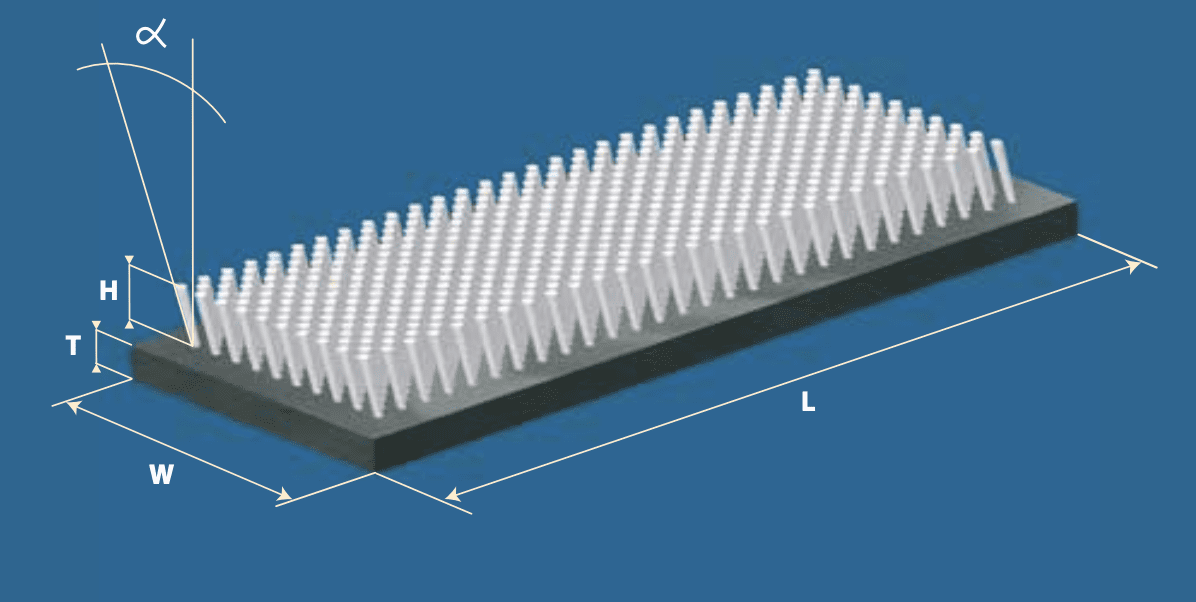

The bundles are generally straight, but it is possible to give them an angle as in the figure, so as to make the brush asymmetrical.

This can be useful to make its action more gentle or to prevent the material from moving in the opposite direction to the motion. The angle α cannot generally exceed 30°.

SX: longitudinal tilt; DX: transverse tilt

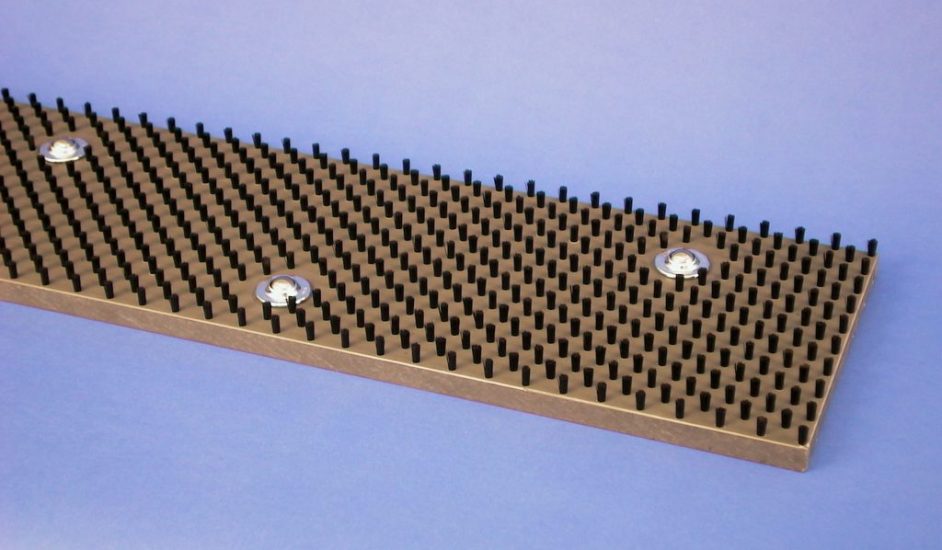

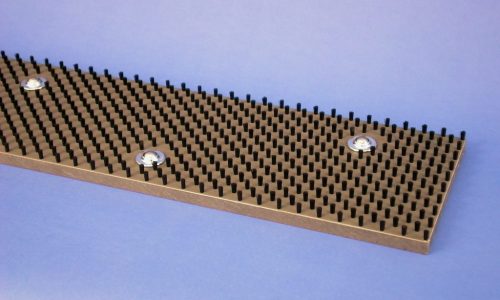

The brush body is generally synthetic, but also made of aluminium in the case of flatness tolerances. Composite materials, such as wooden core and aluminium sheathing, can also be used to achieve lightness and rigidity together.

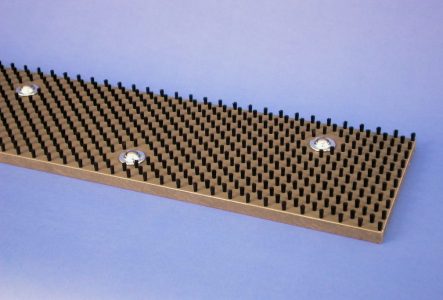

We can also couple a synthetic base with a shaped metal plate to allow for a solid assembly. Normally, flat brushes are mounted on plates. For this purpose, we can provide smooth holes or, on rigid materials such as PVC or aluminium, threaded holes. We can also mount metal threaded inserts. The aluminium brushes can be self-supporting and have slots for mechanical parts.

In order to obtain large brush tables, on which to move or process slabs, several brushes must be arranged side by side. We have therefore developed a modular product that has virtually no size limits. It is a 10 mm thick PVC sheet measuring 200×1500 mm, which has joints on the sides.

The brushes are quickly produced on this basis and then assembled and finally cut to the customer’s drawing. This system, which has been patented by us, allows us to produce large and special parts even in small quantities while maintaining a competitive price.

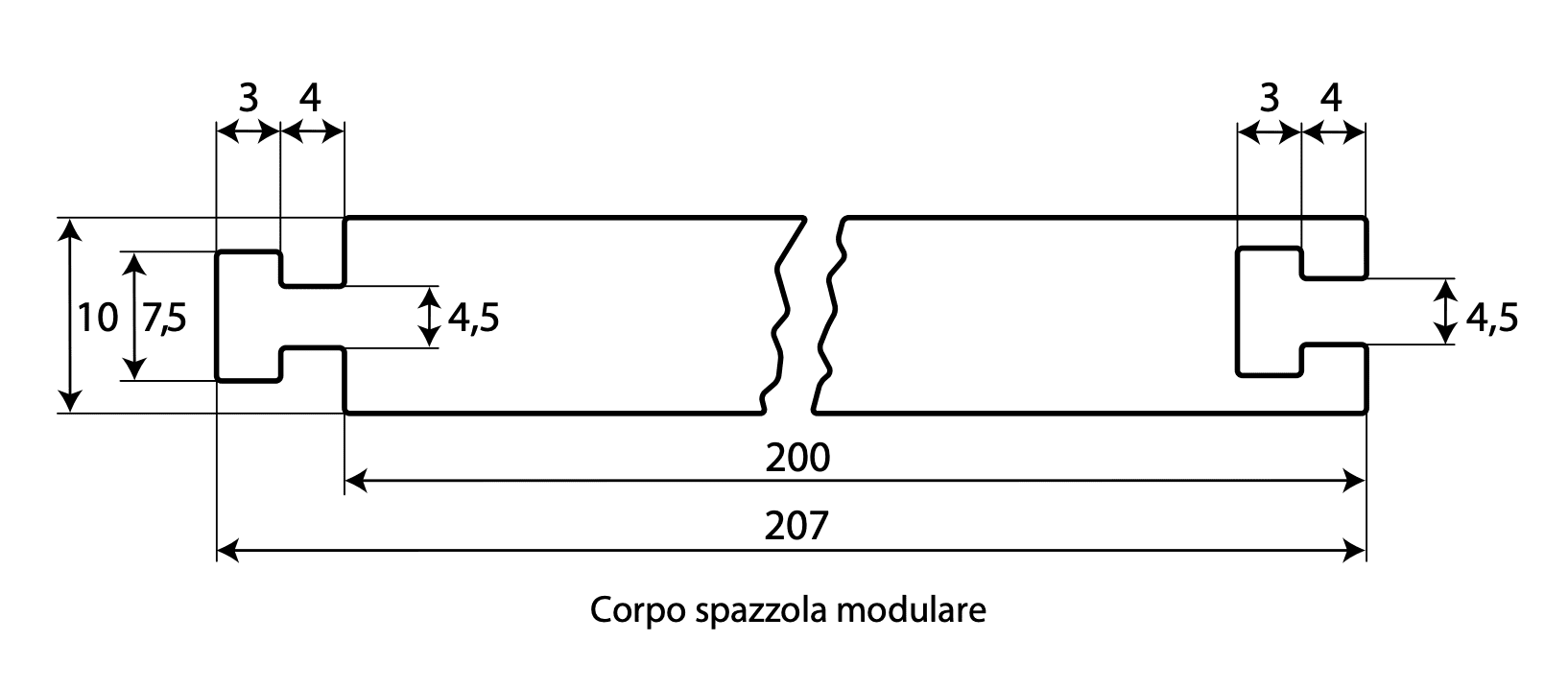

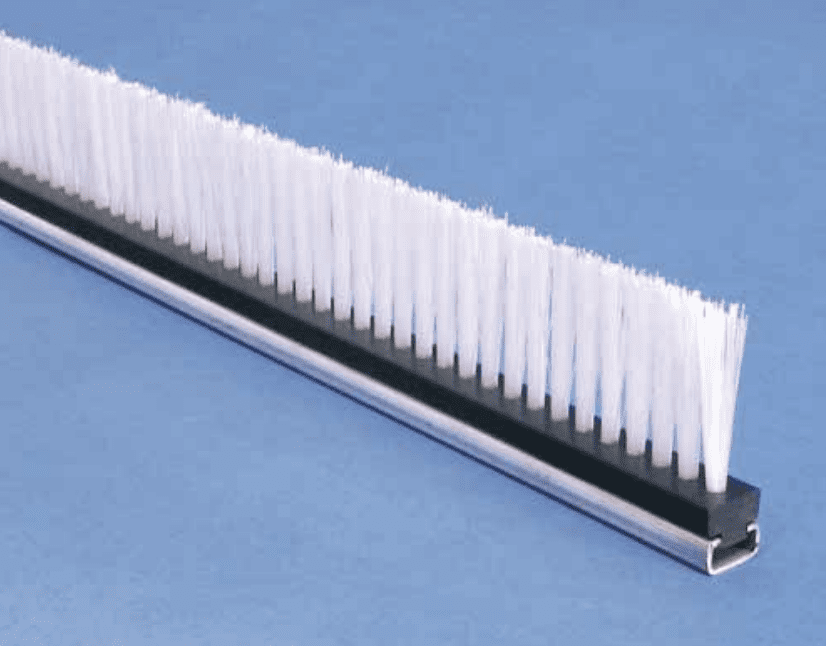

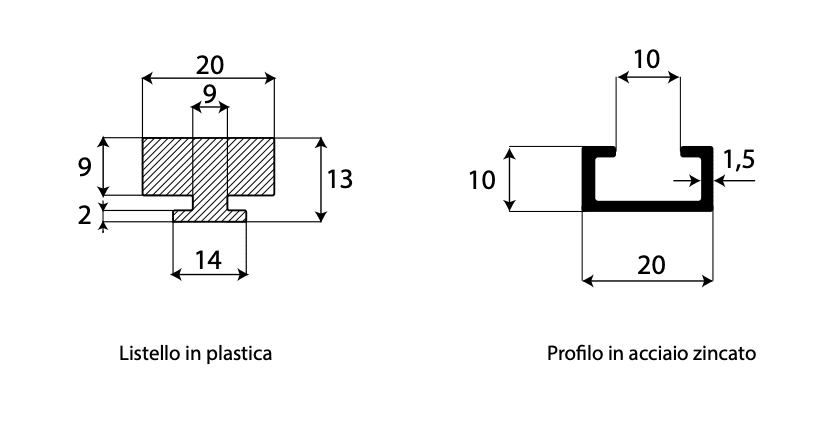

Linear brushes with one or more rows of bundles, to be mounted on a metal profile, are available. The latter gives rigidity and flatness to the brush with a synthetic body, and allows the customer to replace worn strips without changing the mounting system.

A stainless steel profile is also available on request. Below are the standard dimensions of the brush body and its profile. Other sizes are available on request.

Videos and images

GALLERY

Do you want to request an offer?

Are you interested in receiving more information and being contacted by one of our specialized operators?

Request your offer now

Do you want to request an offer?

Are you interested in receiving more information and being contacted by one of our specialized operators?

Request your offer now

Frequently asked questions

What is the advantage of using a brush instead of another deformable object?

The special feature of the brush is that the working surface consists of millions of individual elements, which are the ends of individual filaments.

This gives the brush an adaptability that no other element, however deformable, can have.

How much must the brush interfere with the workpiece?

It depends on various factors. In a nutshell, it can be said that 2 mm is a good compromise. The important thing is that the brush filaments work ‘on the tip’ and not on the side.

Can a bundle of filament be detached from the brush body?

Depending on the materials used and the dimensions, there is a limiting tensile load that an individual bundle can withstand.

Beyond this limit, the bundle comes off, so the brush must be calculated according to use. This limit can be greatly increased by constructing ‘sewn’ or ‘tied’ brushes by hand, where instead of a single anchoring element, a continuous steel wire is placed.

Is a punched brush or a strip cheaper?

There is no single answer. Speaking of e.g. cylindrical brushes, the strip brush is generally cheaper when the dimensions are large (e.g. over one metre in length). For small dimensions, punched brushes are certainly more suitable and convenient.

Is it possible for a single filament to slip out of the bundle and contaminate the product?

This can only happen if the brush has a manufacturing defect, like any other type of object (e.g. a roller made of silicone flakes, one of which is defective and breaks).

When it is important that no contamination occurs, synthetic (not natural) fibres with a diameter greater than or equal to 0.15 mm should be used.

What softness or hardness of brush can I achieve?

Practically all degrees of hardness are possible, from very soft to very hard. In fact, hardness is a combination of the filament diameter, its free length and the density of the bundles.

Is it possible to have a certified 'food grade' brush?

Of course, we can provide FDA or FOOD GRADE certification and filament traceability.

Is it possible to have an ATEX-certified brush?

Unfortunately not, as it is the machine + brush assembly that needs to be ATEX certified, not the brush alone.

However, it is possible to supply the materials that the certifier requires, e.g. conductive bases, conductive filaments, etc.

Is it possible to 'regenerate' a worn-out brush?

Generally speaking, it is possible, but one has to assess whether it is cost-effective, which is not always the case. In addition, in the case of a punched brush, it is inadvisable to regenerate the brush more than twice, so as not to reduce the tightness of the bundles.