Air conveyors

Air conveyors

Generalities

Compressed Air Conveyors inject a small amount of compressed air in order to create a vacuum that carries solid material, as well as fumes and gases, for long distances. Unlike the Coanda effect, which moves large volumes and creates a low vacuum in airflow amplifiers, this system moves a smaller volume but creates a larger vacuum similar to a venturi effect.

A major advantage of these systems is their compact size, along with portability. They don’t possess moving parts. The flow rate can be easily controlled with a pressure regulator.

Common applications include loading freight wagons (resin in the plastics industry, bottle caps in the bottle industry, transporting materials of all types, removing scrap and waste, transferring parts from one place to another, removing splinters, tensioning fibers, and filling operations.

Available air conveyors

Blind-hole cleaning systems

This system has a powerful blower to remove dust and debris from deep holes in components that are difficult to safely clean. The unit is designed so that the hole is completely covered to solve safety problems, while some compressed air is blown inside the hole through specially designed nozzles. In this way, all materials down to the bottom of the hole end up in an attached and easily removable bag. For a more effective and safe cleaning operation, no material is blown out of the component or into the surrounding area.

Smoke and dust extractors

A special item included in the air conveyor section but not a unit that uses the Venturi effect is the Nex Flow® smoke and dust extraction system. In many industrial operations, a small, portable extraction system operating with very little compressed air can be easier to use than expensive and heavy electric-powered units, especially in welding and spot welding operations where a small, portable unit is needed. All you need is a small supply of compressed air.

Drum pumps

The Drum Angel reversible drum pump is a maintenance-free system that uses only compressed air to recover scattered liquids, coolants, sludge, waste oil, wastewater, and other liquids. It easily attaches to any cylindrical vessel (113 L, 204 L, 205 L or 208 L). La sua reversibilità permette di riempire o svuotare il recipiente in meno di due minuti semplicemente girando una maniglia. Without any need for electricity, the Drum Angel system attaches to the small hole above the metal vessel, creating pressure (instead of suction) inside to blow away the liquid.

Ring Vac Conveyors

Available in heavy-duty reinforced anodized aluminum, or stainless steel. Simply attach a standard-sized pump to each end of the Ring-Vac® to create a powerful transport system. There are no moving parts, leading to maintenance-free operation, while capacity and flow are controlled by a pressure regulator.

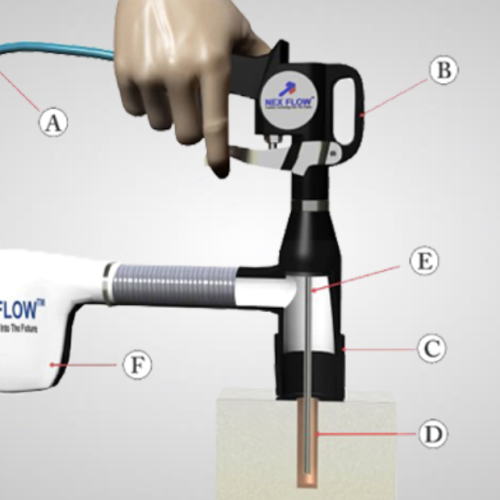

X-Stream suction/blow gun

The X-StreamTM Hand Vac system is the low-cost answer to a variety of industrial cleaning applications. It can become a compressor, an aspirator, a collection system, and a transfer system. It is lightweight, made of aluminum, and consumes less compressed air than a regular compressor. This system creates a powerful suction from one end of it to collect or transport materials. In suction mode, it can be used to suck up debris, which can be collected in a reusable suction bag that is already included in the system.

Do you want to request an offer?

Are you interested in receiving more information and being contacted by one of our specialized operators?

Request your offer now

Do you want to request an offer?

Are you interested in receiving more information and being contacted by one of our specialized operators?

Request your offer now