Coolers

Coolers

Generalities

Why use vortex tubes for industrial and switchboard cooling?

Accessories related to these systems are equipped with highly specialized technologies. Several vendors exist, but few of them seriously understand such technologies. Nex Flow is one of the few doing this and actively researching the field.

A vortex tube is a device that takes compressed air, spins it one way and brings it back, literally dividing the flow into hot and cold air. Cold flow is used for cooling all types of electrical panels and especially for compartments, control panels and industrial camera systems.

The vortex tube technology provided by Nex Flow uses compressed air, but can also use other inert gases, such as nitrogen. Nex Flow has produced special formats and designs and even a model for a natural gas utilization project. Through research and development, Nex Flow continues to come up with new applications for this unique technology and improve product efficiency, which depends on several patented factors

Vortex Tubes offer the following advantages:

- Compactness

- No moving parts

- No electricity

- Lightness

- Portability

Available coolers

Vortex tubes

Vortex tubes are an effective and low-cost solution for a wide variety of industrial spot and process cooling needs.

Frigid-X Panelboard Coolers

Wide range of coolers for panels requiring maintenance. They are ideal for difficult-to-cool environments such as control panels, cabinets, and containers

Silent X-stream Frigid-x series switchboard cooler

They reduce noise levels to 64 dba or more and prevent downtime due to overheating of electronic control panels.

Adjustable coolers

Variable temperature and flow for ideal cooling of laboratories and tests where spot cooling is needed.

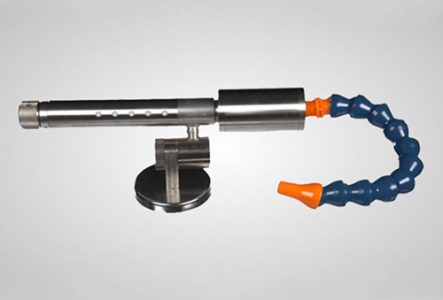

Mini vortex tube

The Mini Spot Cooler is a low-cost, quiet, compact, and maintenance-free system. It uses a vortex tube to produce cold air at one end. The magnetic base is standard to ensure portability and easy mounting of the cooler. Designed for small parts.

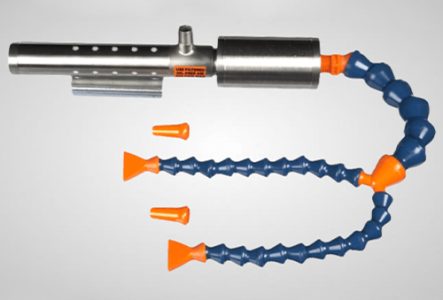

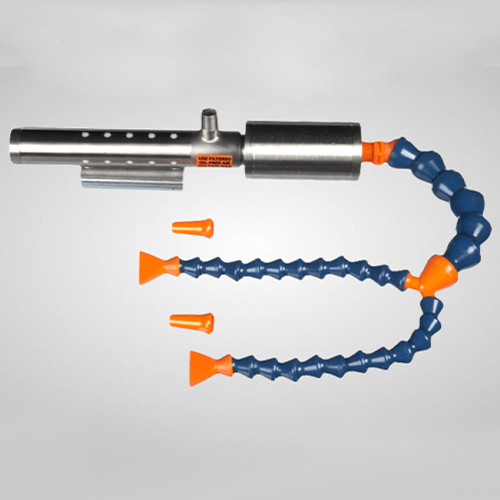

Cutting tool cooling system

The Frigid-X cutting tool cooling system is the ideal product for improving dry machining applications. The traditional emulsified water cooling system is being abandoned wherever possible because of the increased cost of operating and even disposing of the emulsified water coolant. The machines are designed to address many problems in the transition from wet to dry processing, which relate to cleanliness, waste removal, and quality.

Mist systems for tool cooling

Oil-based coolant should be treated and disposed of. Disposal costs are one of the main reasons why efforts are being made to reduce the use of these lubricants. The Mist System is a tool cooler that uses an easily disposable water-based mist. This is when dry cooling is not sufficient.

Do you want to request an offer?

Are you interested in receiving more information and being contacted by one of our specialized operators?

Request your offer now

Do you want to request an offer?

Are you interested in receiving more information and being contacted by one of our specialized operators?

Request your offer now