Spazzole strip lineari

Spazzole strip lineari

Generalità

Le spazzole strip lineari sono utilizzate per:

- blocchiere

- barriera di protezione antinfortunistica in macchine utensili

- barriera per trucioli, polveri, vapori

- racle

- raschiamento di superfici

- fonoisolamento di parti mobili di macchine

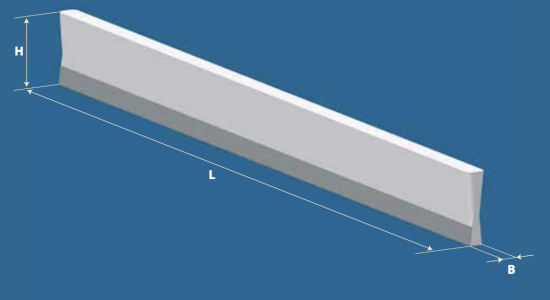

Le spazzole strip lineari hanno lo spessore di base B variabile come indicato in Tabella. La lunghezza L non ha limitazioni, essendo le spazzole prodotte da nastro in modo continuo. Per l’altezza totale H valgono le limitazioni riportate in Tabella.

Non vengono prodotti strip lineari con nastro doppio.

Dimensioni strip lineari (mm)

| B | 4 | 5 | 6 | 8 | 10 | 13 | 14 | 17 | 20 |

|---|---|---|---|---|---|---|---|---|---|

| H MAX | 100 | 150 | 150 | 200 | 200 | 400 | 400 | 400 | 400 |

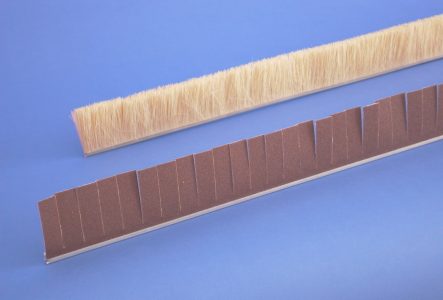

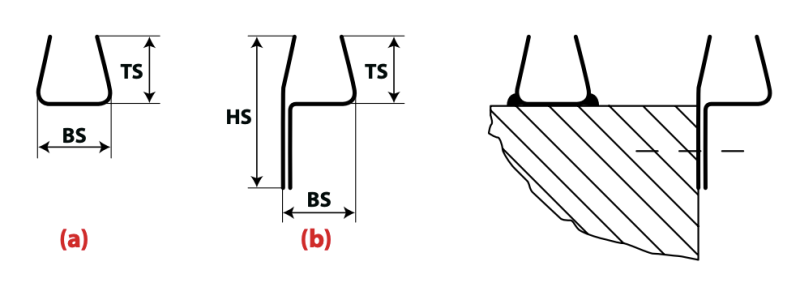

Per il montaggio della spazzola lineare a nastro semplice sono disponibili due tipi di profilato, costruito con robusta lamiera di ferro zincato. Il tipo (a) va saldato al supporto metallico, mentre il tipo (b) va montato tramite viti. Le dimensioni disponibili sono riportate in Tabella. La lunghezza standard è 1000 mm.

Materiali:

- A: alluminio

- AN: alluminio anodizzato nero

- S: acciaio zincato

- X: inox

Dimensioni Guida tipo (a)

| B | 8 | 10 | 13 | 14 | 20 |

|---|---|---|---|---|---|

| BS | 13 | 14 | 19 | 19 | 24 |

| TS | 12 | 12 | 15 | 15 | 27 |

| MAT. | S-X | S-X | S-X | S-X | S |

Dimensioni Guida tipo (b)

| B | 4 | 5 | 8 | 10 | 13 | 14 |

|---|---|---|---|---|---|---|

| BS | 6.5 | 7.1 | 13 | 14 | 19 | 19 |

| TS | 6.5 | 8.8 | 12 | 12 | 17 | 17 |

| HS | 17.5 | 22.3 | 30 | 32 | 40 | 40 |

| MAT. | A-AN | A-AN | A-X | S-X | S | S |

Gli strip lineari possono essere utilizzati anche per ridurre la rumorosità in macchine che hanno parti in movimento, e che quindi non possono essere schermate con elementi rigidi.

Per conoscere il grado di isolamento acustico delle spazzole strip abbiamo costruito un apposito apparato di prova, dove la sorgente di rumore era costituita da un ugello di aria compressa. I risultati sono riportati in Tabella, dove R è il grado di isolamento acustico espresso in dB(A).

Si può vedere che l’isolamento acustico è massimo con filamenti lisci e minimo con filamenti ondulati, indipendentemente dal materiale. Questi risultati sono ottenibili solamente con un’installazione accurata delle spazzole e accertandosi che vi sia contatto tra spazzola e superficie.

Isolamento acustico strip lineari [dB(A)]

| FILAMENTI | R |

|---|---|

| PA 66 0.30 liscio | 8.2 |

| PA 66 0.50 liscio | 7.1 |

| PA 66 1.0 liscio | 5.7 |

| Piattina Acciaio 1.1x0.25 | 5.1 |

| PA 66 0.30 ondulato | 1.5 |

| Ottone 0.30 ondulato | 1.2 |

| Acciaio AR 0.30 ondulato | 0.7 |

| Acciaio AR 0.50 ondulato | 0.7 |

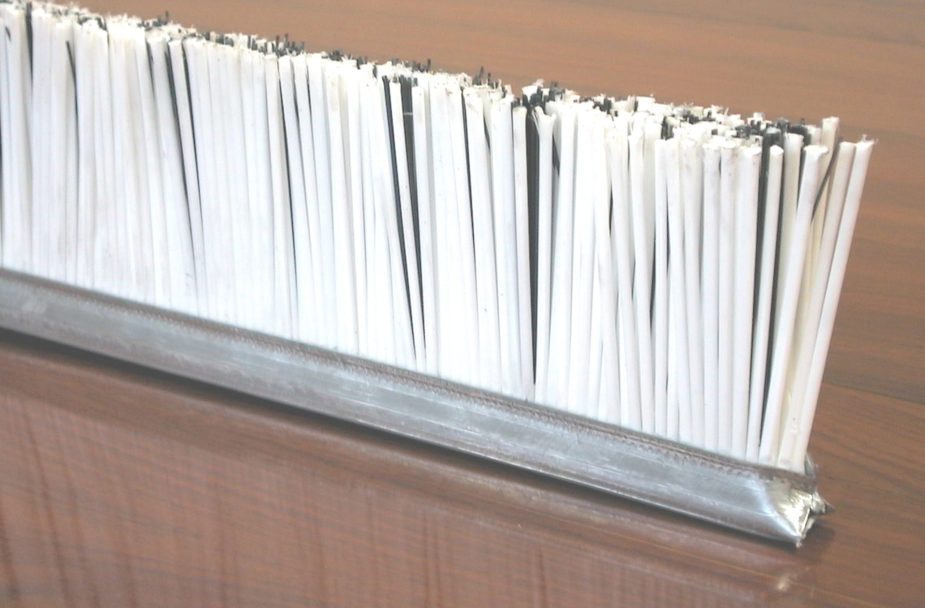

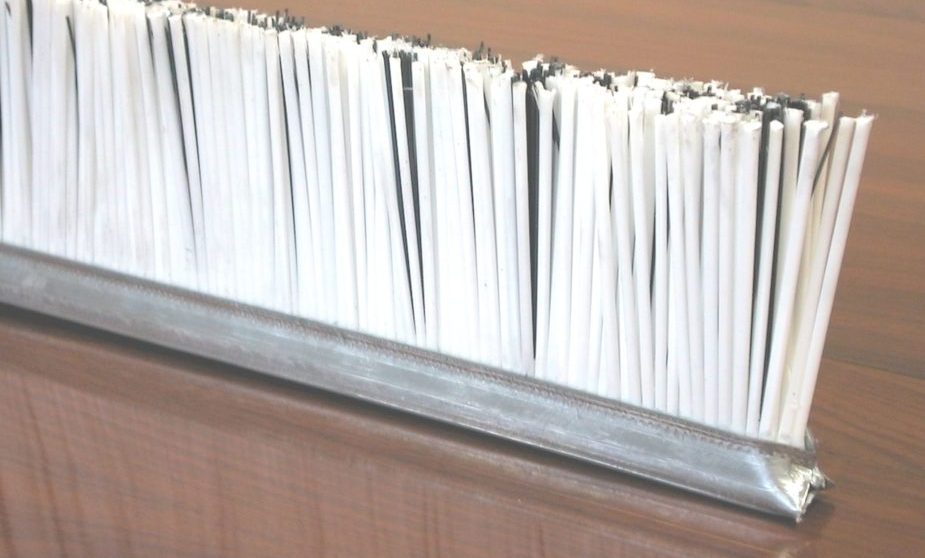

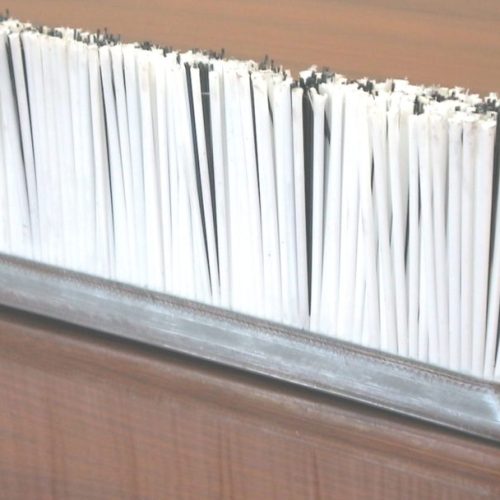

Video e immagini

GALLERIA

Vuoi richiedere un’offerta?

Sei interessato a ricevere maggiori informazioni e ad essere ricontattato da un nostro operatore specializzato?

Richiedi ora la tua offerta

Vuoi richiedere un’offerta?

Sei interessato a ricevere maggiori informazioni e ad essere ricontattato da un nostro operatore specializzato?

Richiedi ora la tua offerta

Domande frequenti

Qual è il vantaggio di usare una spazzola invece di un altro oggetto deformabile?

La caratteristica peculiare della spazzola è che la superficie di lavoro è costituita da milioni di elementi singoli, che sono l’estremità dei singoli filamenti.

Questo conferisce alla spazzola una adattabilità che nessun altro elemento, per quanto deformabile, può avere.

Quanto deve interferire la spazzola sul pezzo da lavorare?

Dipende da vari fattori. In estrema sintesi si può dire che 2 mm è un buon compromesso. L’importante è che i filamenti della spazzola lavorino “di punta” e non sul fianco.

Un mazzetto di filamento si può staccare dal corpo spazzola?

A seconda dei materiali usati e delle dimensioni, esiste un carico limite a trazione che un singolo mazzetto può sopportare.

Oltre questo limite il mazzetto si stacca, quindi la spazzola va calcolata a seconda dell’utilizzo. Si può aumentare moltissimo questo limite costruendo spazzole “cucite” o “legate” a mano, dove invece che un elemento di ancoraggio singolo si mette un filo di acciaio continuo.

È più economica una spazzola punzonata o una strip?

Non c’è una risposta univoca. Parlando ad es.di spazzole cilindriche la spazzola strip è in genere più economica quando le dimensioni sono importanti (es.oltre il metro di lunghezza). Per piccole dimensioni le spazzole punzonate sono sicuramente più adatte e convenienti.

È possibile che un singolo filamento si sfili dal mazzetto contaminando il prodotto?

Può succedere solo se la spazzola ha un difetto di fabbricazione, come d’altra parte ogni altro tipo di oggetto (ad es. un rullo fatto con lamelle di silicone di cui una è difettosa e si spezza).

Quando è importante che non avvenga alcuna contaminazione è opportuno utilizzare fibre sintetiche (non naturali) con diametro maggiore o uguale a 0.15 mm.

Quale morbidezza o durezza di spazzola posso ottenere?

Praticamente si possono avere tutti i gradi di durezza, da morbidissima a durissima. Infatti la durezza è data dalla combinazione tra il diametro del filamento, la sua lunghezza libera e la densità dei mazzetti.

È possibile avere una spazzola certificata “alimentare”?

Certamente, possiamo fornire certificazioni FDA o FOOD GRADE e rintracciabilità del filamento.

È possibile avere una spazzola certificata ATEX?

Purtroppo no, in quanto è l’insieme macchina + spazzola a dover essere certificata ATEX, non la sola spazzola.

E’ comunque possibile fornire i materiali che il certificatore richiede, ad es. basi conduttive, filamenti conduttivi ecc…

È possibile “rigenerare” una spazzola consumata?

In linea generale è possibile, bisogna però valutare se è economicamente conveniente, e non sempre lo è. Inoltre, nel caso di una spazzola punzonata, è sconsigliabile rigenerare la spazzola più di due volte per non ridurre la tenuta dei mazzetti.