Blowers

Blowers

Generalities

Why use energy-efficient and compressed air blowing products?

Energy-efficient blowing products from Nex Flow reduce noise and improve blowing, cooling and ventilation operations. The use of compressed air is most effective when “designed” appropriately following the laws of pneumatics. The most effective method involves the use of the “Coanda” effect, which inserts atmospheric air into the compressed air that escapes from a small “vacuum” or hole in the blowing product, so as to convert the pressure that is normally lost and noise into a usable flow. This has the additional effect of considerably reducing noise levels. Other ideas, such as the “Laval effect,” have been tried, but with poor results in performance and real noise reduction and energy savings. The “Coanda” effect remains the most reliable and effective way to improve the effectiveness of a blowing product, although it is not the only factor. Any turbulence must be reduced. As air moves in, out and around the blowing product, it affects its performance. An appropriately designed nozzle “converts” pressure into flow with minimal energy loss. This requires a balanced approach. By considering air movement and minimizing turbulence, it optimizes the ideal amount of inlet air for a particular application. When air comes out of a small “hole” in the blowing product, it is “atmospheric air” that is mixed with discharged air. Even if the airflow remains laminar for a long distance, the velocity will decrease. The blowing force that “hits” the target depends on both mass flow and velocity. There is a balance and a “range” within which flow and speed are most effective. If the incoming air is too much, the velocity will drop to a level where the blowing force is negligible. This provides a particularly interesting result relative to air nozzles and for the real effectiveness of “Air Conveyors,” or annular units called Air Amplifiers.

The main products for air amplification are air blades, air nozzles, air sprayers, air conveyors or air amplifiers, and air dryers. Air amplification technology is simple, lightweight, compact, low-cost, and easy to install and will offer immediate benefits on energy savings by reducing noise levels and improving your industrial environment.

Available blowers

Air amplifiers

Nex Flow air amplifiers are low-cost, maintenance-free devices. They are used to convey vapors, smoke, light materials and move a large amount of air for cooling, blowing and drying operations. Due to the “Coanda” effect to convey the surrounding air, they use small amounts of compressed air. They can amplify airflow up to 17 times (depending on size) with reduced noise levels.

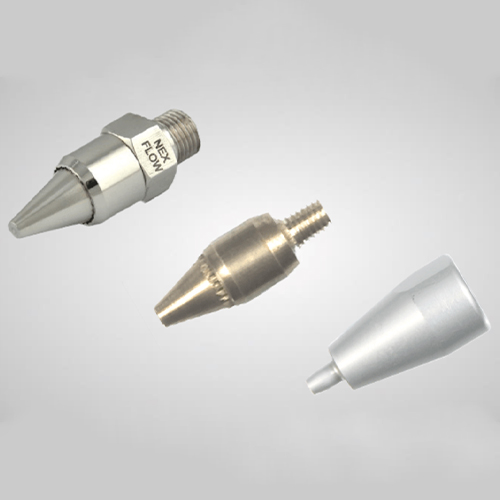

Air nozzles

Air nozzles are small flow amplifiers to be used at a specific point. There are conical ones and those with a star shape (Air Mag). The latter provide a powerful laminar outflow. Thus, star nozzles provide greater force with higher air consumption.

Air Dryer Ring Blade

The Ring Blade Air Dryeris by Nex Flow is a lightweight, compact and easy-to-use tool that produces a 360-degree jet of air around the object. It reduces the use of compressed air to save energy and greatly reduces noise levels. Such systems are essentially maintenance-free, and the jet can be easily controlled with a regulator.

Air blades

Nex Flow Air Blade Systems utilize compressed air for industrial cooling and blowing operations. They are used intensively to replace sets of air nozzles, sprayers or perforated tubes to reduce energy. The curtain airflow of the Air Blades is an effective way to dry, clean and cool. Energy reduction by air blades is between 30% and 90% depending on the application, and can have a noise reduction of 10 to 15 dBA and more.

Air Edger Flat Air Sprayers

The Model 47011 Air Edger Flat Jet air sprayer is designed to provide a powerful source of laminar flow at high speed and force, to cool and blow where air blades are not powerful enough. Air blades are ideal for blowing away liquids and dust, but when heavier materials require more “force” to be moved, this product is what is needed for the job.

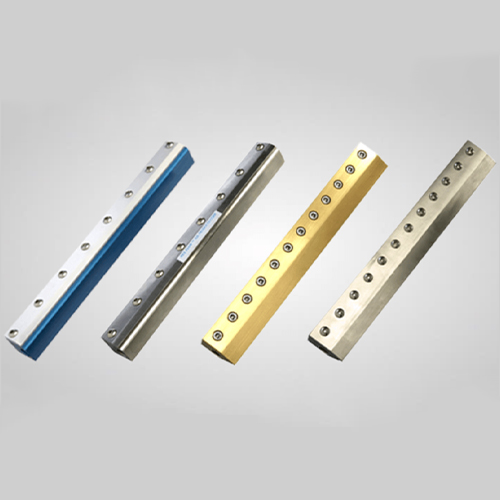

Multi-channel mounting systems

Multi-channel systems allow nozzles to be mounted in combination between two, four or six tools for blowing and cooling applications where air blades cannot be used and where some blowing power is required.

Safety air guns

Nex Flow safety air guns are durable, safe and convenient to use and incorporate our efficient air nozzles and jets to produce high-performance air and “laminar” flow, minimizing compressed air use and noise levels.

Do you want to request an offer?

Are you interested in receiving more information and being contacted by one of our specialized operators?

Request your offer now

Do you want to request an offer?

Are you interested in receiving more information and being contacted by one of our specialized operators?

Request your offer now