Spazzole punzonate piane

Spazzole punzonate piane

Generalità

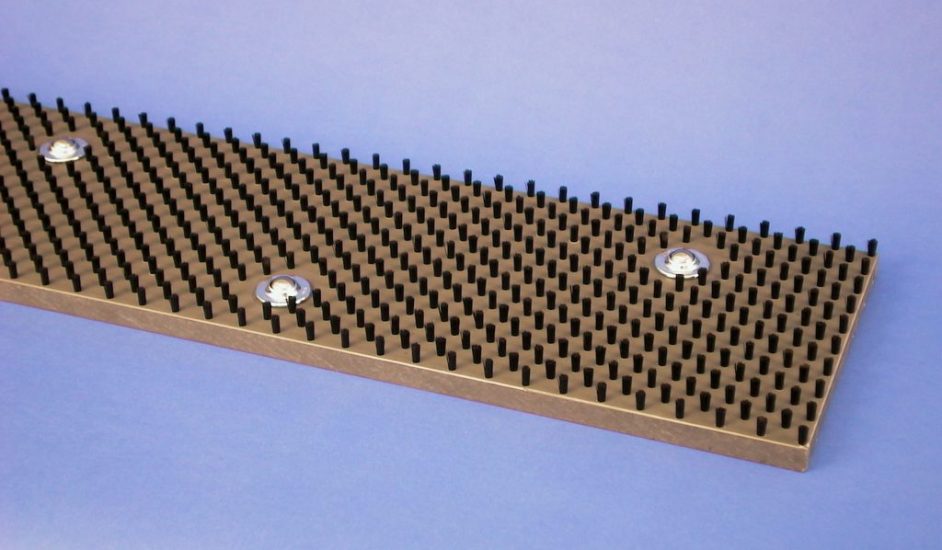

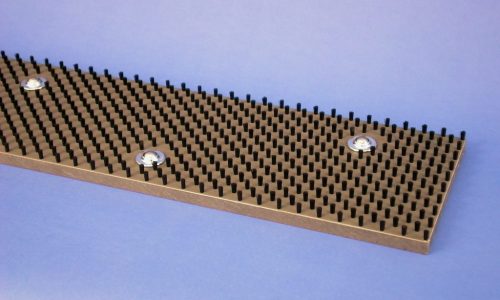

Generalmente sono montate su parti fisse di macchine, a volte possono anche essere installate su tamburi cilindrici a costituire un rullo o su slitte con moto alternativo. La superficie di lavoro può essere continua, a settori o sagomata secondo disegno del cliente. In queste spazzole è spesso fondamentale la planarità, sia per quanto riguarda il corpo spazzola che la rasatura, che definisce la superficie di lavoro.

Le spazzole piane sono utilizzate per:

- Spazzole di precisione

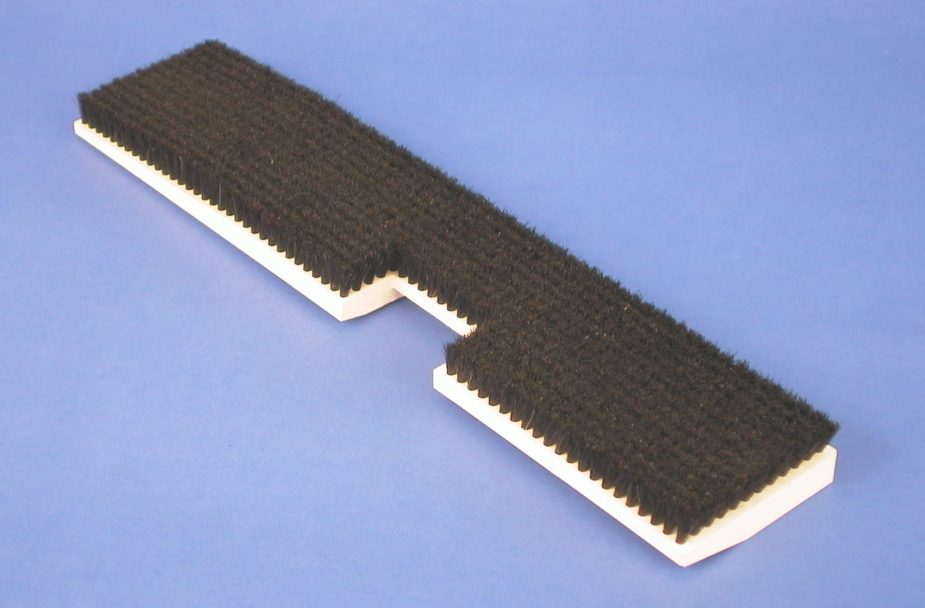

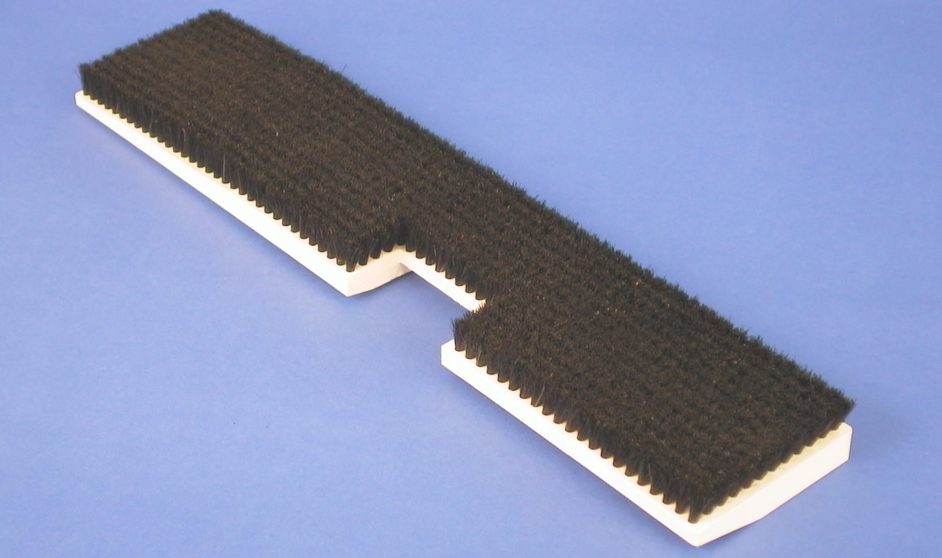

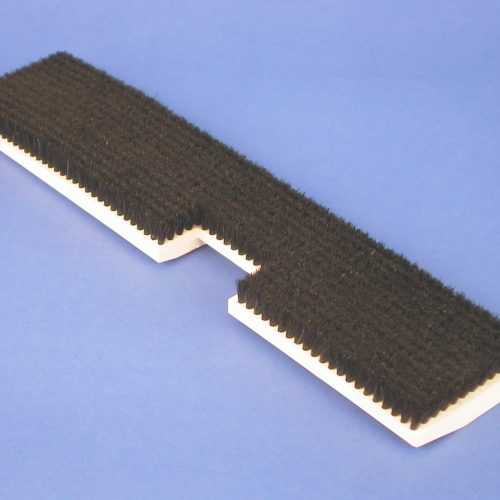

- Spazzole con forme geometriche complesse

- Piani di trasporto

- Guide per lo scorrimento di prodotti

- Barriere di forma complessa per trucioli e polveri

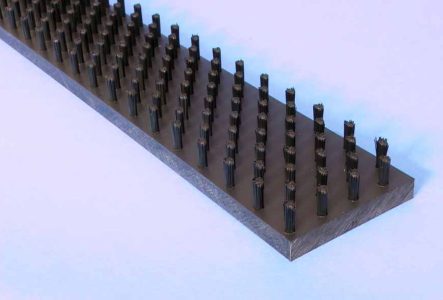

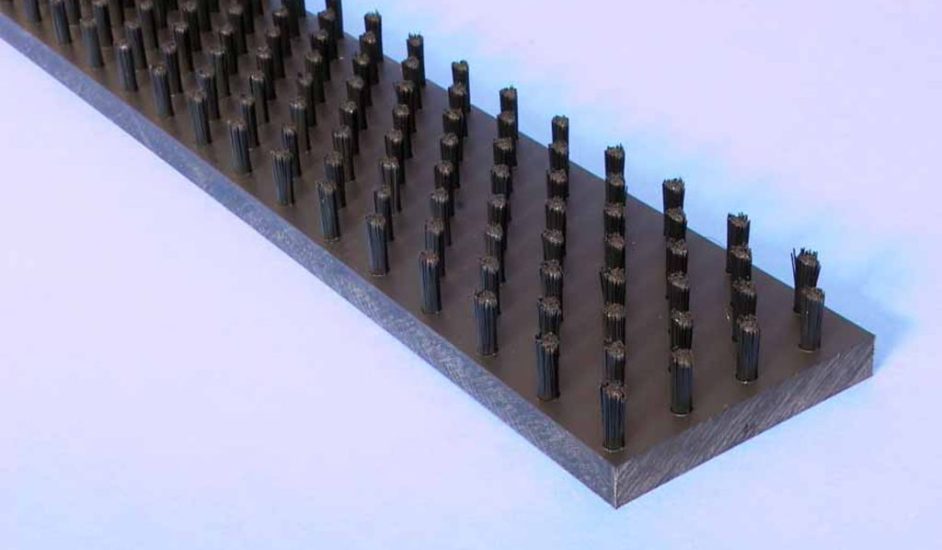

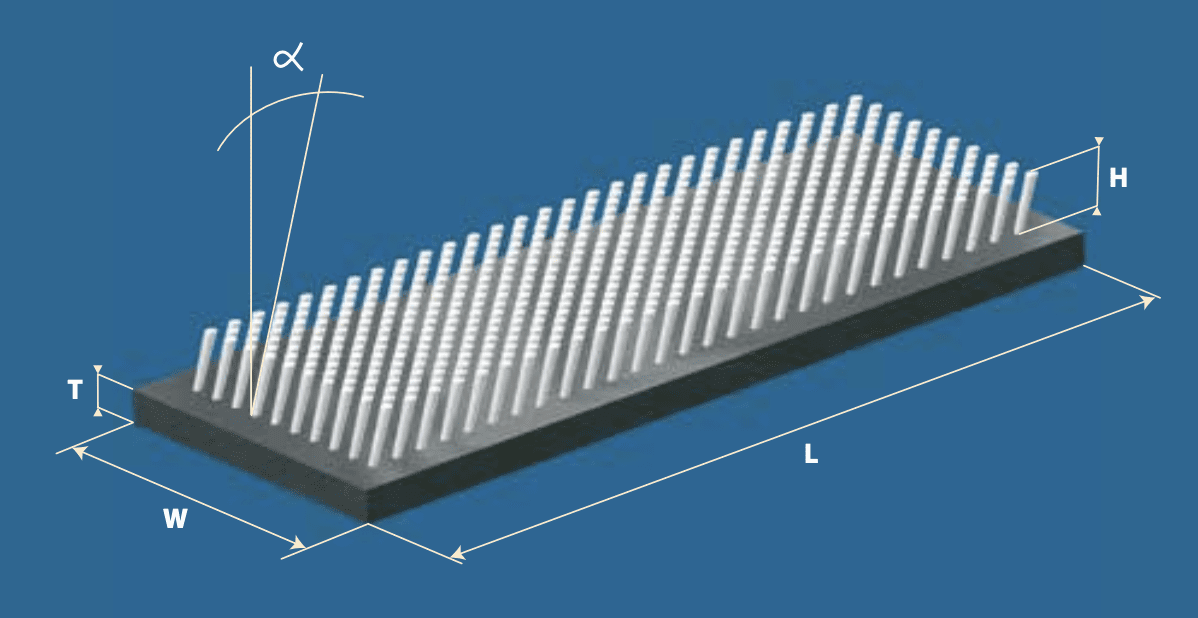

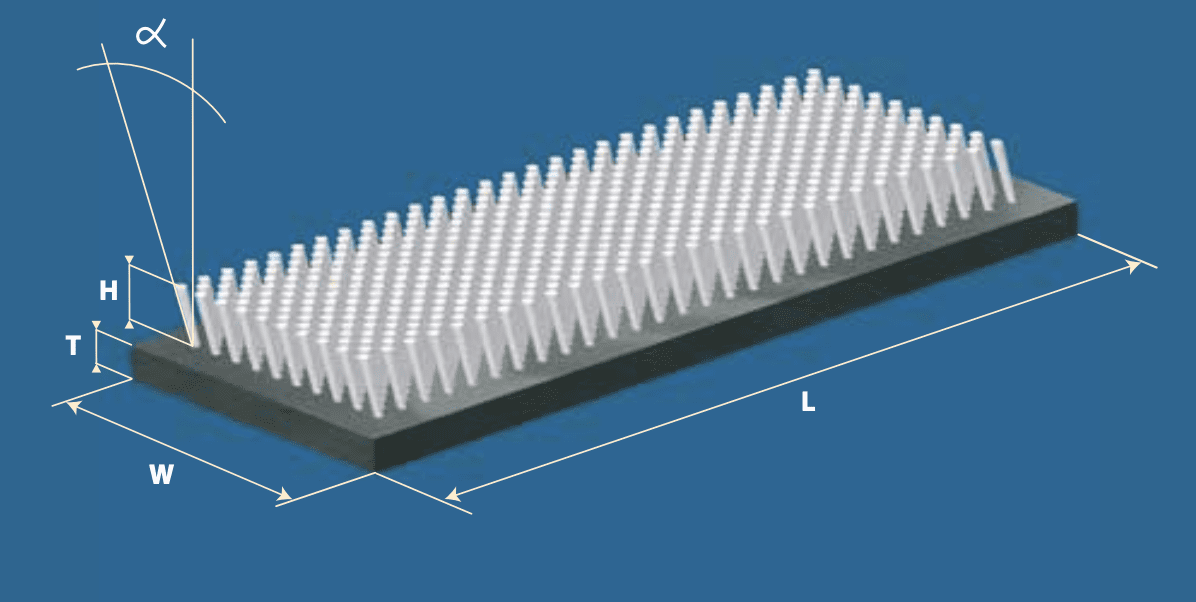

I mazzetti sono generalmente diritti, ma è possibile dare loro un’inclinazione come in Figura, in modo da rendere asimmetrica la spazzola.

Ciò può essere utile per rendere più delicata la sua azione o per impedire lo spostamento del materiale in senso contrario al moto. L’angolo α non può generalmente superare i 30°.

SX: Inclinazione longitudinale ; DX: Inclinazione trasversale

Il corpo spazzola è generalmente sintetico, ma anche in alluminio in caso di tolleranze sulla planarità. Possono essere utilizzati anche materiali compositi, come nocciolo in legno e guaina in alluminio per avere leggerezza e rigidità insieme.

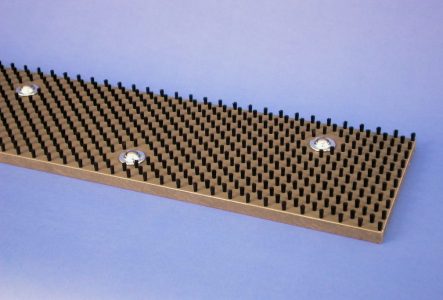

Possiamo anche accoppiare una base sintetica con una lastra metallica sagomata per consentire un solido montaggio. Normalmente le spazzole piane sono montate su piastre. Per questo scopo possiamo prevedere fori lisci o, su materiali rigidi come PVC o alluminio, fori filettati. Possiamo anche montare inserti filettati metallici. Le spazzole in alluminio possono essere autoportanti ed avere incastri per parti meccaniche.

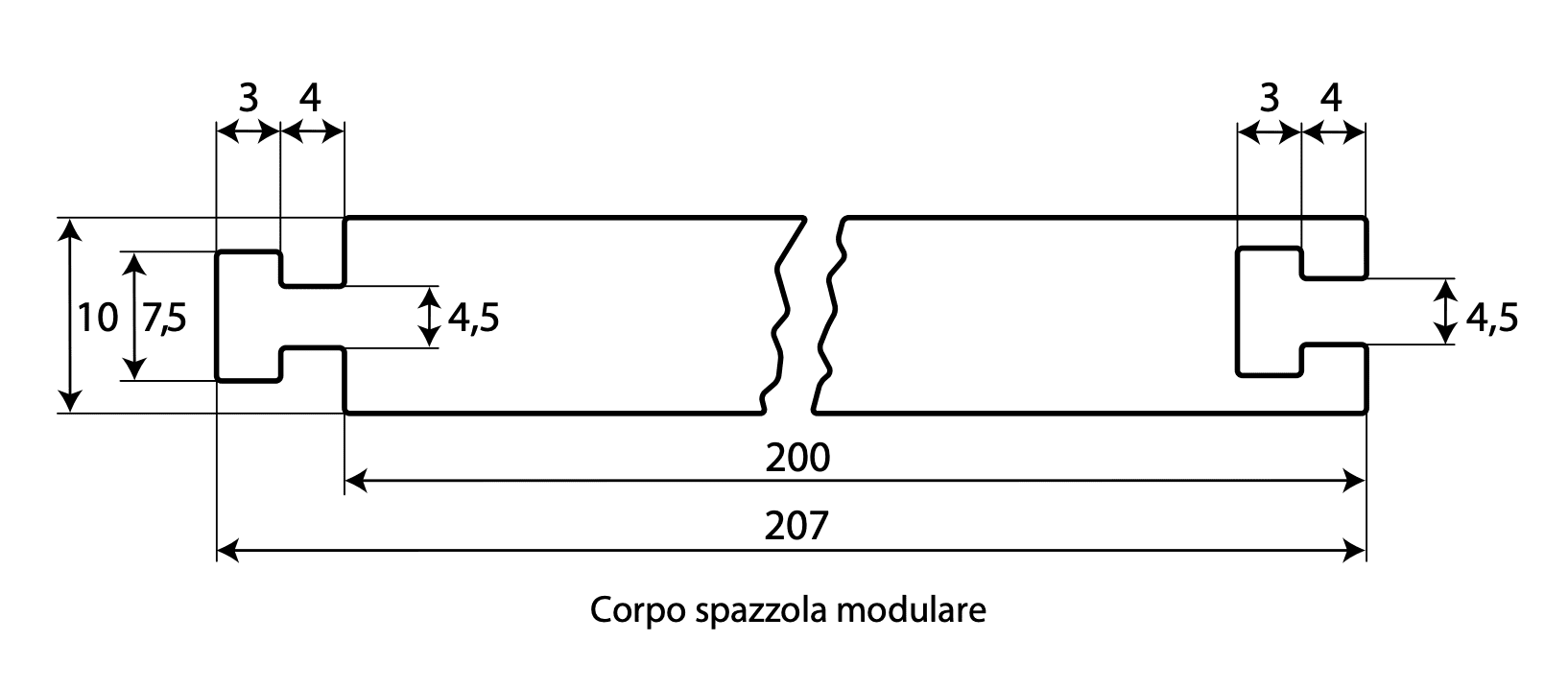

Per ottenere piani a spazzola di grandi dimensioni, su cui movimentare o lavorare lastre, occorre comporre più spazzole una a fianco dell’altra. Abbiamo quindi sviluppato un prodotto modulare che non ha praticamente limiti dimensionali. Si tratta di una lastra di PVC di 10 mm di spessore con misure 200×1500 mm, che presenta ai lati degli incastri.

Le spazzole vengono prodotte velocemente su questa base e poi assemblate ed infine tagliate secondo il disegno del cliente. Questo sistema, che è stato da noi brevettato, ci consente di produrre pezzi grandi e speciali anche in piccole quantità mantenendo un prezzo competitivo.

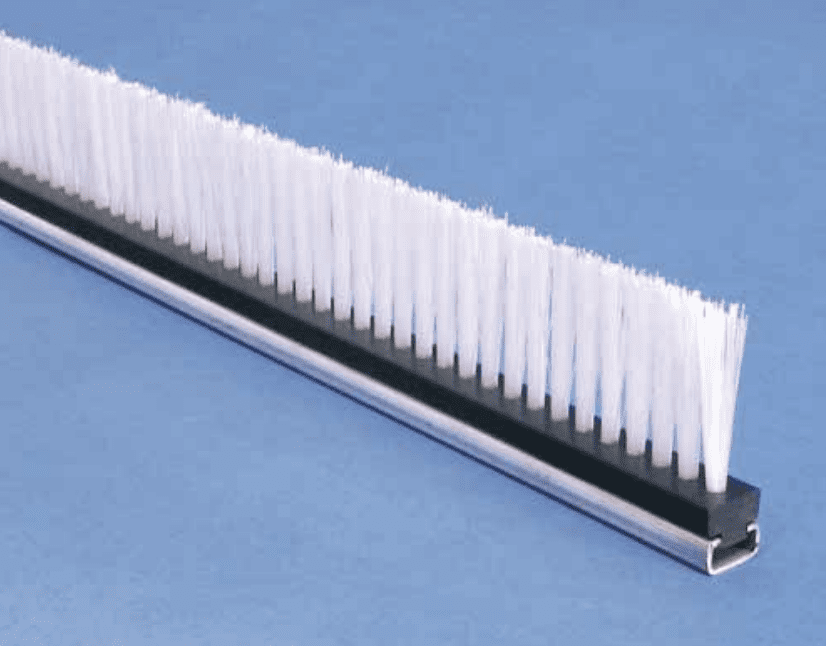

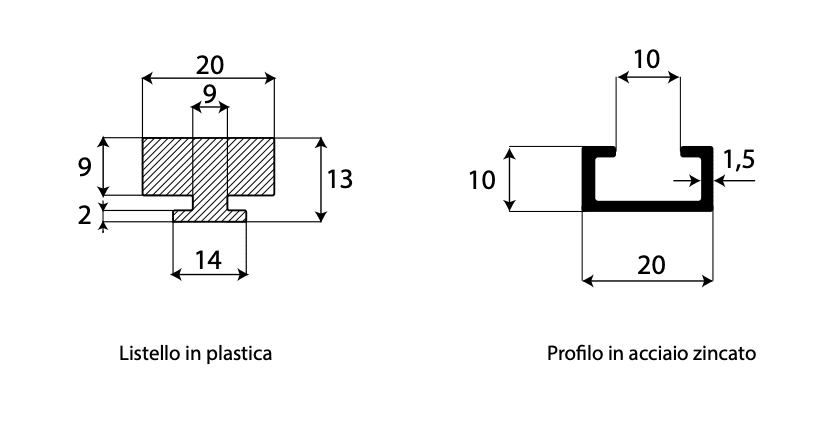

Sono disponibili spazzole lineari con una o più file di mazzetti, da montare su profilo metallico. Quest’ultimo conferisce rigidità e planarità alla spazzola con corpo sintetico, e permette al cliente di sostituire i listelli usurati senza intervenire sul sistema di montaggio.

È disponibile, su richiesta, anche il profilo inox. Riportiamo di seguito la misura standard del corpo spazzola e del relativo profilo. Altre misure sono disponibili su richiesta.

Video e immagini

GALLERIA

Vuoi richiedere un’offerta?

Sei interessato a ricevere maggiori informazioni e ad essere ricontattato da un nostro operatore specializzato?

Richiedi ora la tua offerta

Vuoi richiedere un’offerta?

Sei interessato a ricevere maggiori informazioni e ad essere ricontattato da un nostro operatore specializzato?

Richiedi ora la tua offerta

Domande frequenti

Qual è il vantaggio di usare una spazzola invece di un altro oggetto deformabile?

La caratteristica peculiare della spazzola è che la superficie di lavoro è costituita da milioni di elementi singoli, che sono l’estremità dei singoli filamenti.

Questo conferisce alla spazzola una adattabilità che nessun altro elemento, per quanto deformabile, può avere.

Quanto deve interferire la spazzola sul pezzo da lavorare?

Dipende da vari fattori. In estrema sintesi si può dire che 2 mm è un buon compromesso. L’importante è che i filamenti della spazzola lavorino “di punta” e non sul fianco.

Un mazzetto di filamento si può staccare dal corpo spazzola?

A seconda dei materiali usati e delle dimensioni, esiste un carico limite a trazione che un singolo mazzetto può sopportare.

Oltre questo limite il mazzetto si stacca, quindi la spazzola va calcolata a seconda dell’utilizzo. Si può aumentare moltissimo questo limite costruendo spazzole “cucite” o “legate” a mano, dove invece che un elemento di ancoraggio singolo si mette un filo di acciaio continuo.

È più economica una spazzola punzonata o una strip?

Non c’è una risposta univoca. Parlando ad es.di spazzole cilindriche la spazzola strip è in genere più economica quando le dimensioni sono importanti (es.oltre il metro di lunghezza). Per piccole dimensioni le spazzole punzonate sono sicuramente più adatte e convenienti.

È possibile che un singolo filamento si sfili dal mazzetto contaminando il prodotto?

Può succedere solo se la spazzola ha un difetto di fabbricazione, come d’altra parte ogni altro tipo di oggetto (ad es. un rullo fatto con lamelle di silicone di cui una è difettosa e si spezza).

Quando è importante che non avvenga alcuna contaminazione è opportuno utilizzare fibre sintetiche (non naturali) con diametro maggiore o uguale a 0.15 mm.

Quale morbidezza o durezza di spazzola posso ottenere?

Praticamente si possono avere tutti i gradi di durezza, da morbidissima a durissima. Infatti la durezza è data dalla combinazione tra il diametro del filamento, la sua lunghezza libera e la densità dei mazzetti.

È possibile avere una spazzola certificata “alimentare”?

Certamente, possiamo fornire certificazioni FDA o FOOD GRADE e rintracciabilità del filamento.

È possibile avere una spazzola certificata ATEX?

Purtroppo no, in quanto è l’insieme macchina + spazzola a dover essere certificata ATEX, non la sola spazzola.

E’ comunque possibile fornire i materiali che il certificatore richiede, ad es. basi conduttive, filamenti conduttivi ecc…

È possibile “rigenerare” una spazzola consumata?

In linea generale è possibile, bisogna però valutare se è economicamente conveniente, e non sempre lo è. Inoltre, nel caso di una spazzola punzonata, è sconsigliabile rigenerare la spazzola più di due volte per non ridurre la tenuta dei mazzetti.