Spazzole punzonate a rullo

Spazzole punzonate a rullo

Generalità

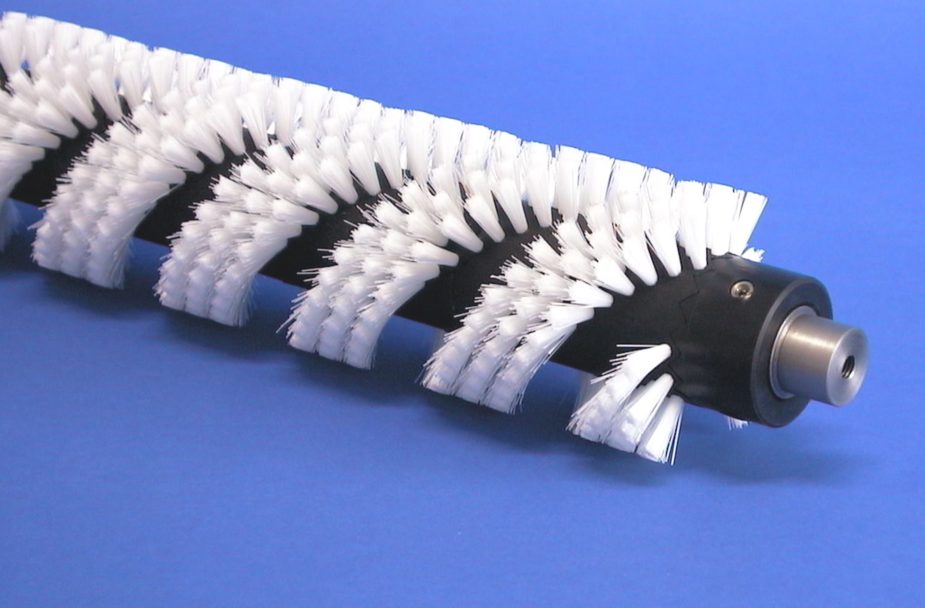

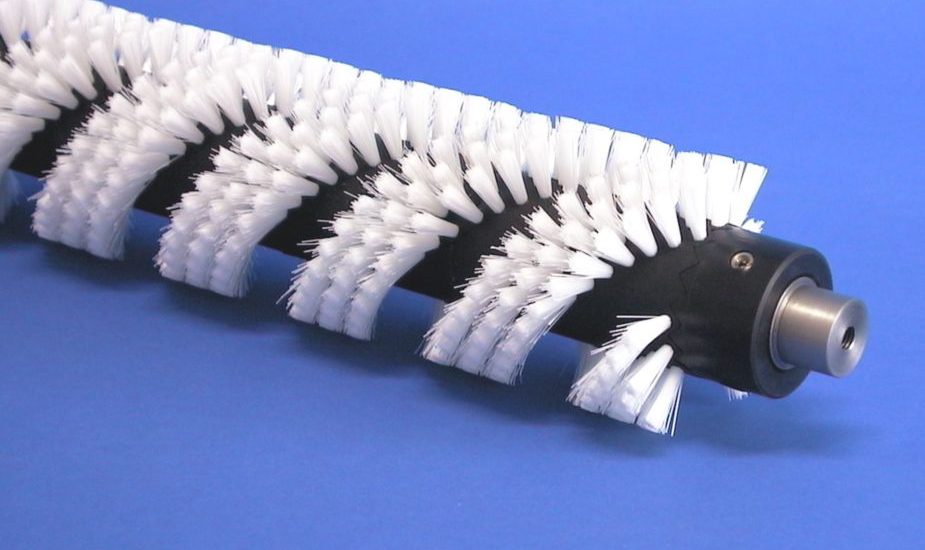

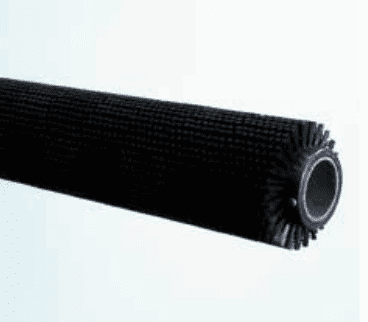

Sono la tipologia più diffusa nell’industria, in quanto utilizzate in molti processi produttivi. Generalmente sono spazzole motorizzate, quindi dotate di nucleo metallico adatto a sopportare notevoli momenti torcenti. Possono tuttavia anche essere fornite senza nucleo metallico. La superficie di lavoro può essere continua, a settori, ad elica, conica, sagomata secondo disegno. Per rulli di grandi dimensioni o rotanti ad elevata velocità è importante l’operazione di equilibratura dinamica, che realizziamo al nostro interno con la possibilità di fornire al cliente il certificato di equilibratura dettagliato.

I rulli sono utilizzati per :

- Spazzole di precisione

- Spazzole con forme geometriche complesse

- Spazzole con filamenti misti o settori alternati di filamenti diversi

- Spazzole modulari componibili

- Spazzole morbide e delicate

I mazzetti sono generalmente radiali, ma è possibile dare loro un’inclinazione trasversale, in modo da rendere rotazionalmente asimmetrica la spazzola.

Ciò può essere utile per rendere più delicata l’azione del rullo o per impedire lo spostamento del materiale in senso contrario al moto. L’angolo α non può generalmente superare i 30°.

I rulli sono quasi sempre motorizzati. Per questo si prevedono corpi spazzola in acciaio con mozzi, flange, sedi per linguette, ecc.

A volte per motivi tecnici si realizzano rulli su corpo composito con differenti materiali. L’equilibratura dinamica si può eseguire solamente su rulli con corpo metallico, in quanto “non deformabili”.

Le spazzole a rullo con D1>L prendono il nome di spazzole circolari.

Possono lavorare in spazi ridotti ed essere affiancate sullo stesso albero fino ad ottenere un rullo, che però non avrà la stessa continuità di un pezzo unico.

Un dato importante da conoscere in fase di progetto è la velocità di rotazione a cui si può portare un rullo. Questo dato dipende , oltre che dai materiali, dal carico utilizzato sulla spazzola e dal coefficiente di attrito filamento-superficie. Possiamo calcolare il numero di giri accettabile n della spazzola con una funzione ‘f’ dei parametri statici e dinamici e verificare che sia :

n < f (s, Ft, Pm, D1, D2, P) dove s = coefficiente di sicurezza, che deve tenere conto del tipo di carico applicato Ft = resistenza del mazzetto allo strappo [Kg] Pm = peso del mazzetto [gr] P = profondità del foro dei mazzetti [mm].

Siamo a disposizione per fornirvi i necessari dati di progetto. Con elevate velocità occorre in ogni caso realizzare un campione e testarlo in condizioni di sicurezza.

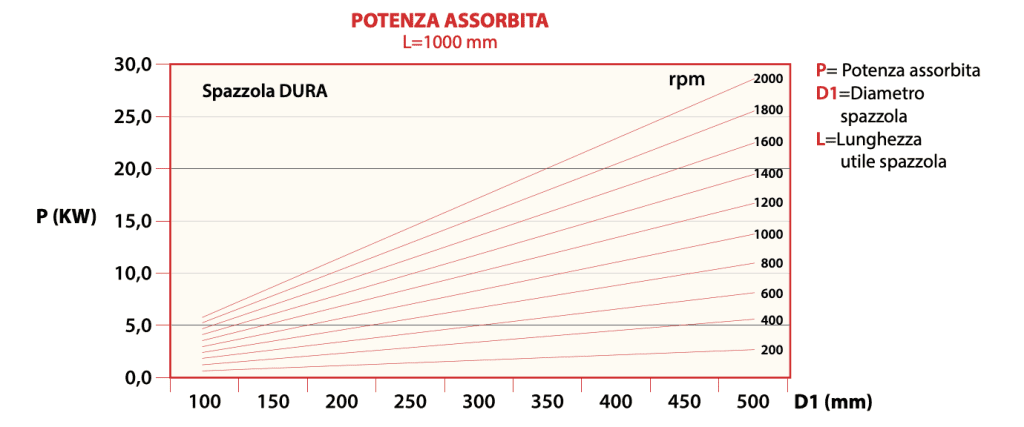

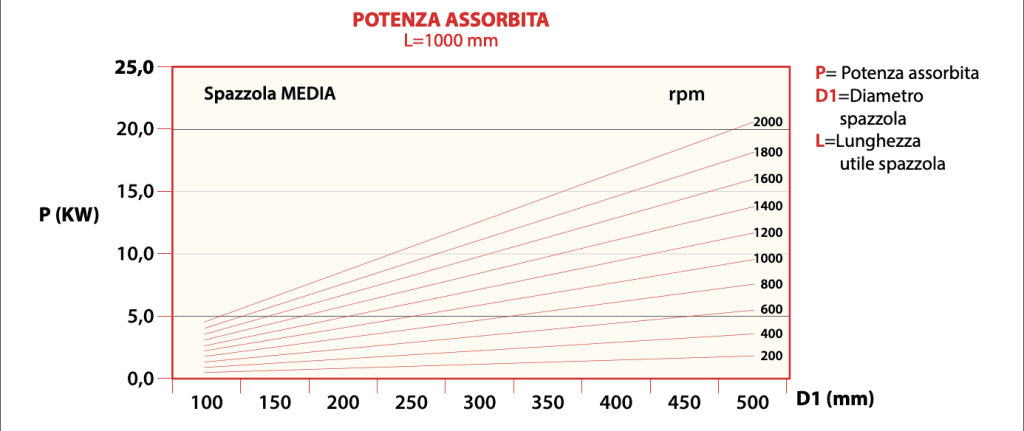

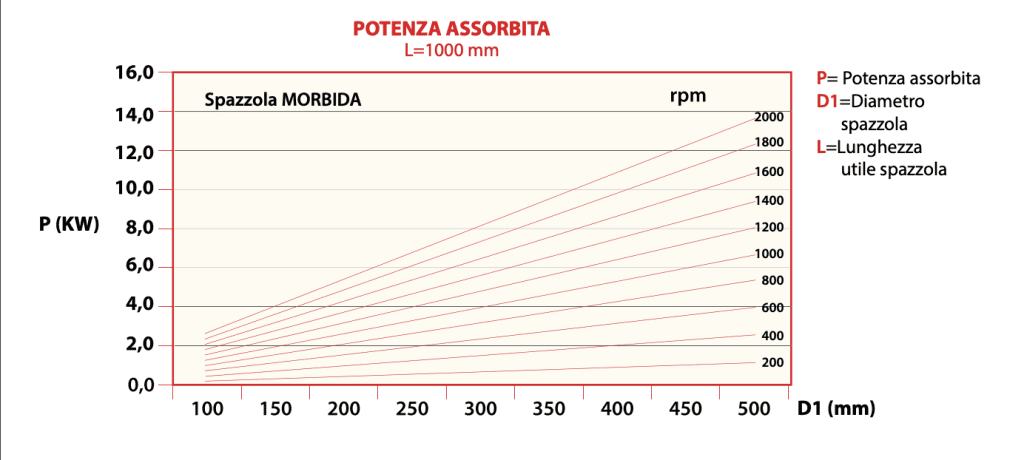

È importante prevedere un idoneo motore per la movimentazione della spazzola a rullo. La potenza assorbita varia in funzione del diametro spazzola, del numero di giri, della lunghezza di lavoro e della durezza del filamento. Inoltre risente in modo determinante della pressione esercitata sulla spazzola.

È pertanto possibile stabilire la potenza solo come valore medio ed in prima approssimazione. I diagrammi riportati forniscono la potenza del motore per una spazzola di lunghezza 1000 mm.

Per lunghezze diverse si segue la proporzione aritmetica.

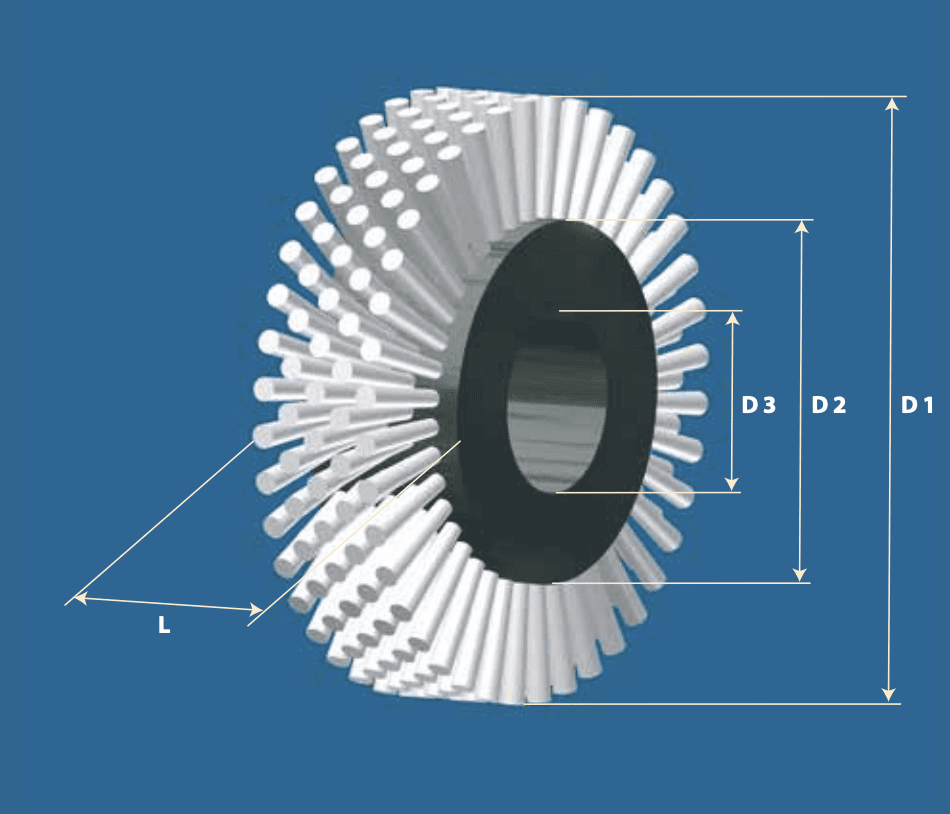

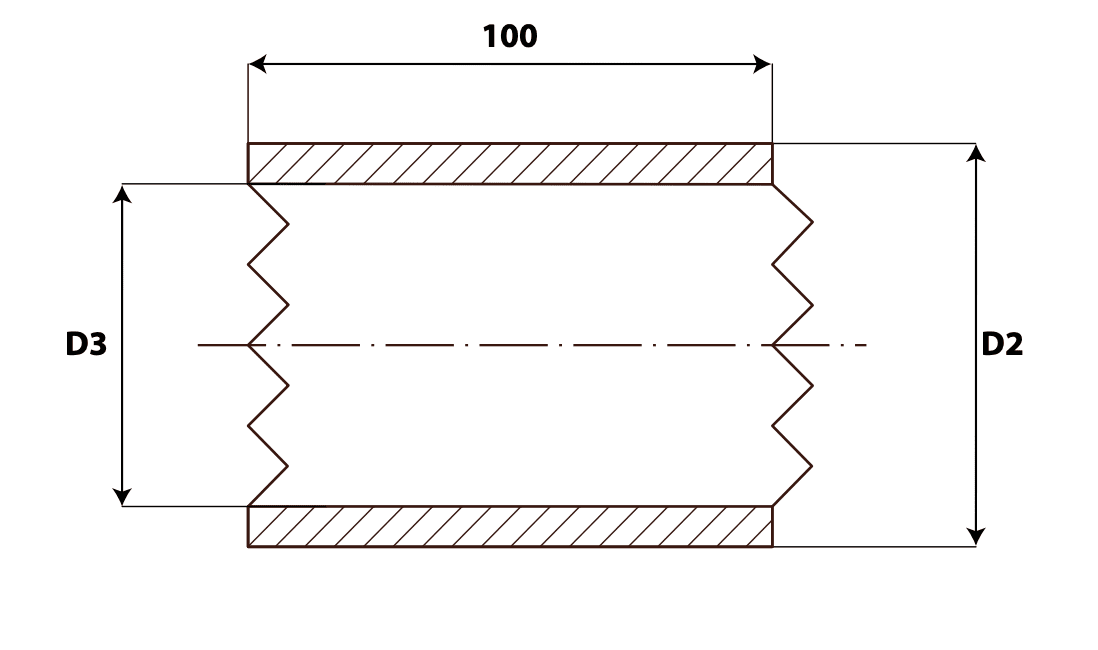

È possibile comporre rulli della lunghezza desiderata utilizzando moduli di lunghezza standard 100 mm.

I moduli sono dei cilindri di vari diametri e fori, che presentano alle due estremità una dentatura che ha due funzioni:

- trasmettere il moto tra due moduli

- realizzare la continuità della superficie spazzolante anche nelle linee di giunzione. Alle estremità del rullo così composto vi sono due collari dentati con grano filettato che bloccano la spazzola.

Il corpo spazzola è costruito in PP, ed è disponibile anche la versione bianca per uso alimentare. La superficie spazzolante può essere continua, a settori o a spirale. Il numero di mazzetti dipende direttamente dal numero dei denti Z, per cui si possono avere spazzole con diverse densità, secondo la tabella. I rulli modulari hanno il vantaggio di poter formare spazzole di diversa lunghezza, sono di facile sostituzione e trasporto. Per contro presentano una certa limitazione in diametri e disposizione dei mazzetti. Infatti questi parametri sono vincolati alle caratteristiche del corpo spazzola, che essendo ottenuto per stampaggio non consente tutte le possibilità. In altri termini, il metodo modulare può sostituire la spazzola tradizionale fatta in un unico pezzo solo per le dimensioni standard riportate in tabella.

Corpi spazzola modulari L = 100 mm

| D2 (mm) | D3 (mm) | Z | R |

|---|---|---|---|

| 31 | 20 | 6 | B |

| 31 | 20 | 8 | M |

| 31 | 20 | 10 | A |

| 45 | 25 | 8 | B |

| 45 | 25 | 12 | M |

| 45 | 25 | 16 | A |

| 50 | 30 | 10 | B |

| 50 | 30 | 12 | M |

| 50 | 30 | 16 | A |

| 57 | 35 | 10 | B |

| 57 | 35 | 15 | M |

| 57 | 35 | 18 | A |

| 65 | 40 | 12 | B |

| 65 | 40 | 17 | M |

| 65 | 40 | 20 | A |

| 75 | 50 | 12 | B |

| 75 | 50 | 18 | M |

| 75 | 50 | 30 | A |

| 86 | 60 | 12 | B |

| 86 | 60 | 20 | M |

| 86 | 60 | 30 | A |

| 100 | 75 | 14 | B |

| 100 | 75 | 18 | M |

| 100 | 75 | 22 | A |

| 125 | 100 | 18 | B |

| 125 | 100 | 24 | M |

| 125 | 100 | 28 | A |

Z = Numero denti; R = Reticolo; B = Bassa intensità; M = Media intensità; A = Alta intensità

è una spazzola studiata appositamente per la pulizia dei pannelli fotovoltaici e solari. È noto infatti che i pannelli necessitano di una pulizia periodica per evitare che, a causa di polveri di vario genere, riducano la loro efficienza. Sunny Brush è modulare, in modo da adattarsi alle varie tipologie di pannelli esistenti in commercio.

Gli elementi costitutivi sono:

- nucleo in alluminio in moduli da 1.000 mm

- spazzola D=200 mm in nylon in moduli da 100 mm

- boccole di giunzione in POM-C con inserti filettati

- collari di bloccaggio e finitura delle estremità La modularità consente all’utilizzatore di ordinare una spazzola della lunghezza desiderata (anche molti metri) e di assemblarla facilmente anche sul tetto utilizzando delle semplici viti. Altri vantaggi della modularità (sia del nucleo che delle spazzole) sono l’economicità e la semplicità di trasporto.

Video e immagini

GALLERIA

Vuoi richiedere un’offerta?

Sei interessato a ricevere maggiori informazioni e ad essere ricontattato da un nostro operatore specializzato?

Richiedi ora la tua offerta

Vuoi richiedere un’offerta?

Sei interessato a ricevere maggiori informazioni e ad essere ricontattato da un nostro operatore specializzato?

Richiedi ora la tua offerta

Domande frequenti

Qual è il vantaggio di usare una spazzola invece di un altro oggetto deformabile?

La caratteristica peculiare della spazzola è che la superficie di lavoro è costituita da milioni di elementi singoli, che sono l’estremità dei singoli filamenti.

Questo conferisce alla spazzola una adattabilità che nessun altro elemento, per quanto deformabile, può avere.

Quanto deve interferire la spazzola sul pezzo da lavorare?

Dipende da vari fattori. In estrema sintesi si può dire che 2 mm è un buon compromesso. L’importante è che i filamenti della spazzola lavorino “di punta” e non sul fianco.

Un mazzetto di filamento si può staccare dal corpo spazzola?

A seconda dei materiali usati e delle dimensioni, esiste un carico limite a trazione che un singolo mazzetto può sopportare.

Oltre questo limite il mazzetto si stacca, quindi la spazzola va calcolata a seconda dell’utilizzo. Si può aumentare moltissimo questo limite costruendo spazzole “cucite” o “legate” a mano, dove invece che un elemento di ancoraggio singolo si mette un filo di acciaio continuo.

È più economica una spazzola punzonata o una strip?

Non c’è una risposta univoca. Parlando ad es.di spazzole cilindriche la spazzola strip è in genere più economica quando le dimensioni sono importanti (es.oltre il metro di lunghezza). Per piccole dimensioni le spazzole punzonate sono sicuramente più adatte e convenienti.

È possibile che un singolo filamento si sfili dal mazzetto contaminando il prodotto?

Può succedere solo se la spazzola ha un difetto di fabbricazione, come d’altra parte ogni altro tipo di oggetto (ad es. un rullo fatto con lamelle di silicone di cui una è difettosa e si spezza).

Quando è importante che non avvenga alcuna contaminazione è opportuno utilizzare fibre sintetiche (non naturali) con diametro maggiore o uguale a 0.15 mm.

Quale morbidezza o durezza di spazzola posso ottenere?

Praticamente si possono avere tutti i gradi di durezza, da morbidissima a durissima. Infatti la durezza è data dalla combinazione tra il diametro del filamento, la sua lunghezza libera e la densità dei mazzetti.

È possibile avere una spazzola certificata “alimentare”?

Certamente, possiamo fornire certificazioni FDA o FOOD GRADE e rintracciabilità del filamento.

È possibile avere una spazzola certificata ATEX?

Purtroppo no, in quanto è l’insieme macchina + spazzola a dover essere certificata ATEX, non la sola spazzola.

E’ comunque possibile fornire i materiali che il certificatore richiede, ad es. basi conduttive, filamenti conduttivi ecc…

È possibile “rigenerare” una spazzola consumata?

In linea generale è possibile, bisogna però valutare se è economicamente conveniente, e non sempre lo è. Inoltre, nel caso di una spazzola punzonata, è sconsigliabile rigenerare la spazzola più di due volte per non ridurre la tenuta dei mazzetti.